Electricity connection method for electric heating film

A technology of electric heating film and electric method, which is applied in the direction of electric heating device, ohmic resistance heating, conductive adhesive connection, etc., can solve the problems of unreliable connection between connecting wire and electric heating film, complicated process, etc., and achieve improved reliability and firm connection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

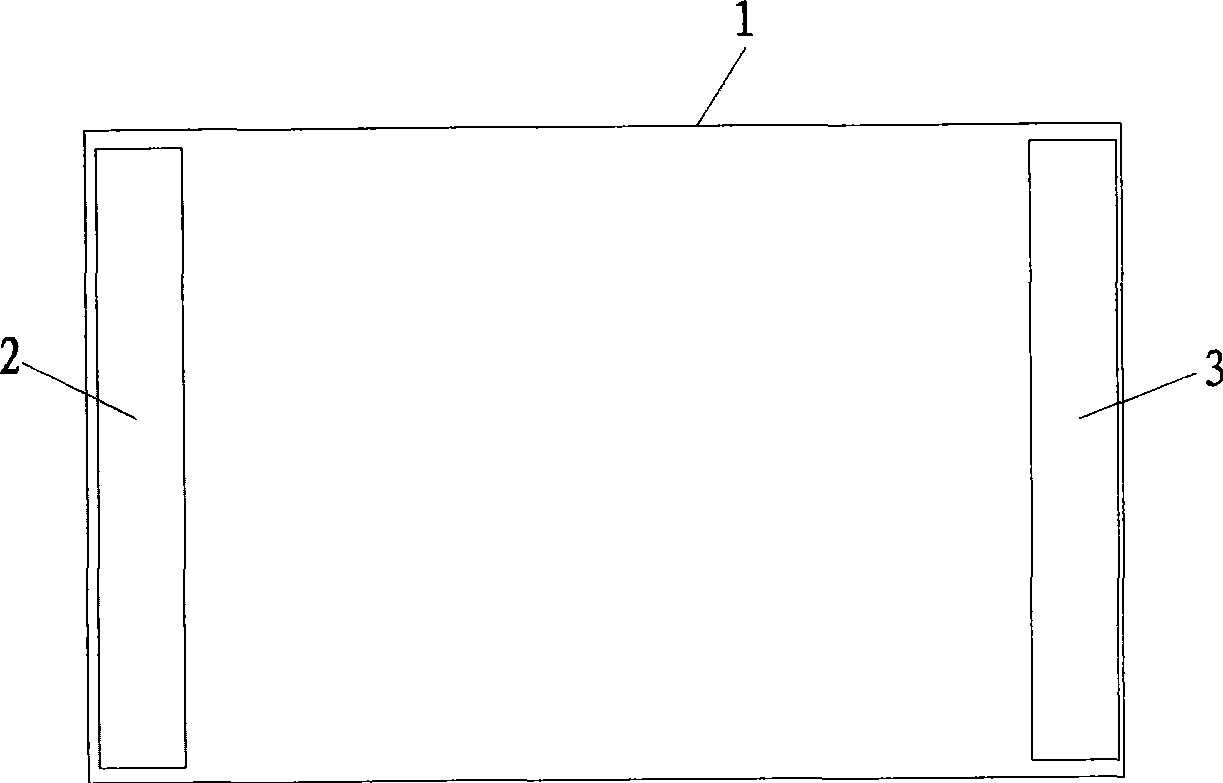

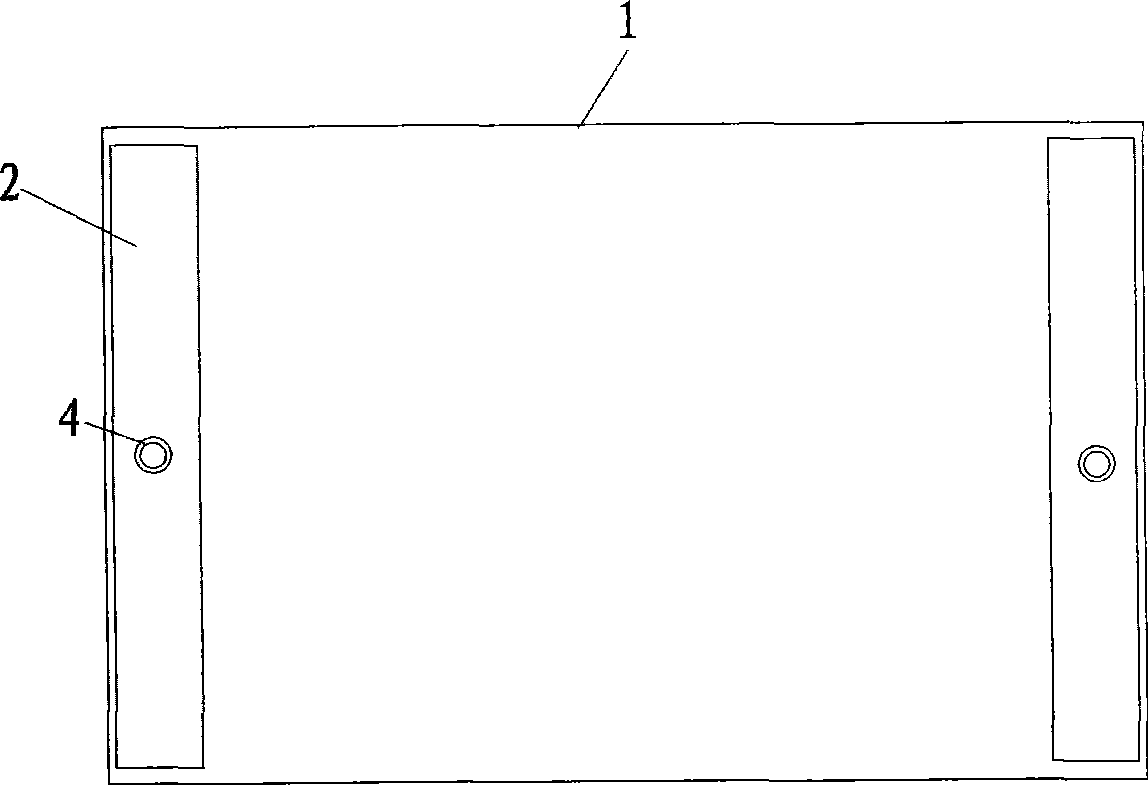

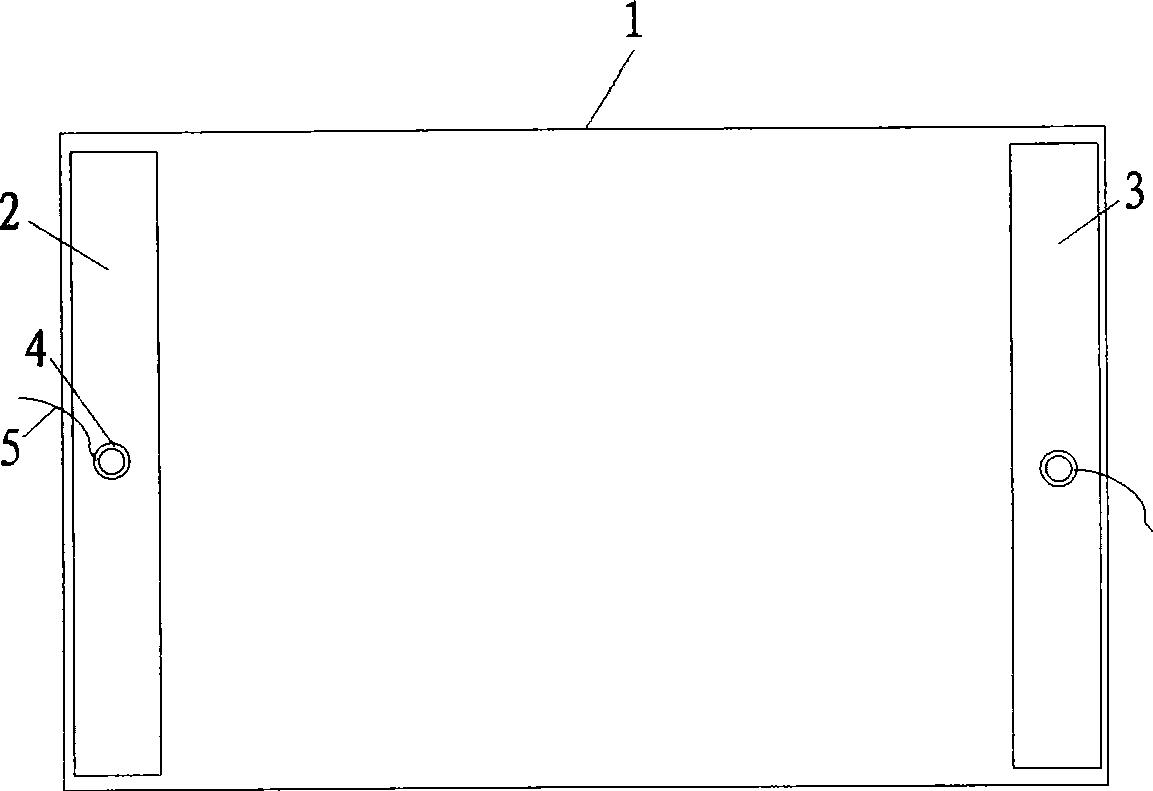

[0023] As shown in the figure, a layer of electrothermal film is coated on the surface of the electrothermal film carrier 1, and the electrothermal film carrier can be various dielectric materials such as glass, ceramics, enamel, mica, quartz, and glass-ceramic. Both sides of the electrothermal film carrier are coated with layered electrodes 2, 3, and the layered electrodes 2, 3 are connected in series with the electrothermal film.

[0024] The method of the present invention is as follows: Firstly, grooves are made in the middle of the layered electrodes 2 and 3 on the electrothermal film carrier. The grooves are preferably circular grooves 4, and may also be "V" shaped grooves or square grooves. Then place one end of the connecting wire 5 in the circular groove 4, the connecting wire 5 in the present invention is preferably a pure silver wire. Then pour the conductive glue 6 into the annular groove 4 until it is full, and the conductive glue is preferably silver paste. Fina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com