Interdigital capacitor sensor for cereal moisture percentage

A technology of interdigitated capacitance and moisture content, applied in the direction of material capacitance, etc., can solve problems such as being susceptible to interference and unable to measure the moisture content inside grains, and achieve the effects of improving sensitivity, realizing non-contact measurement, and being easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

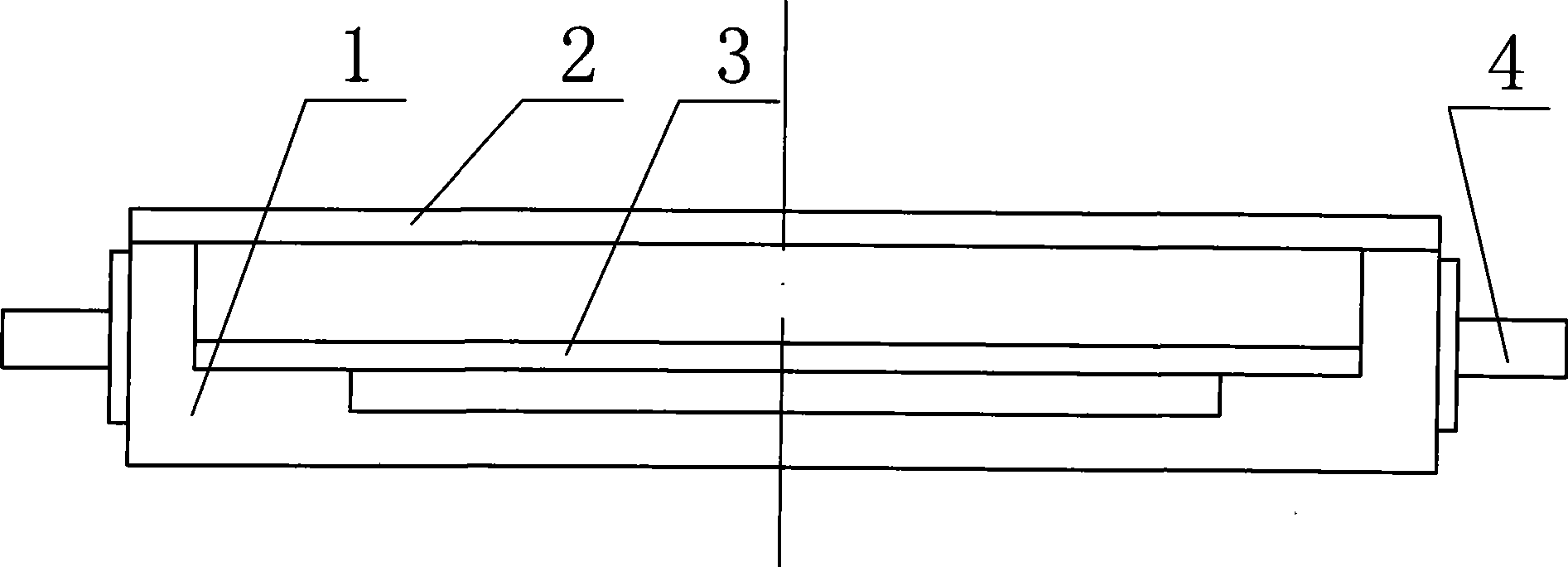

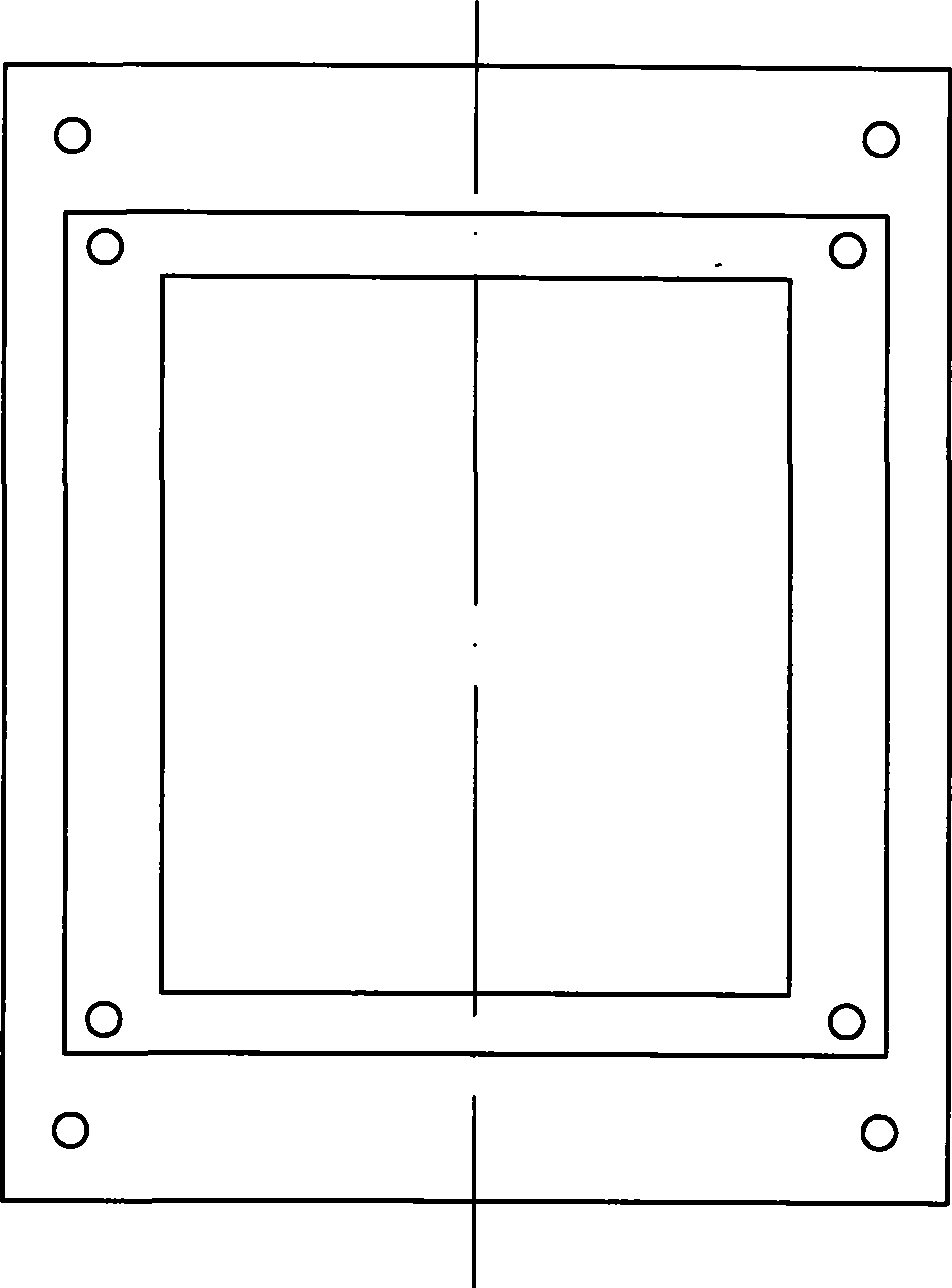

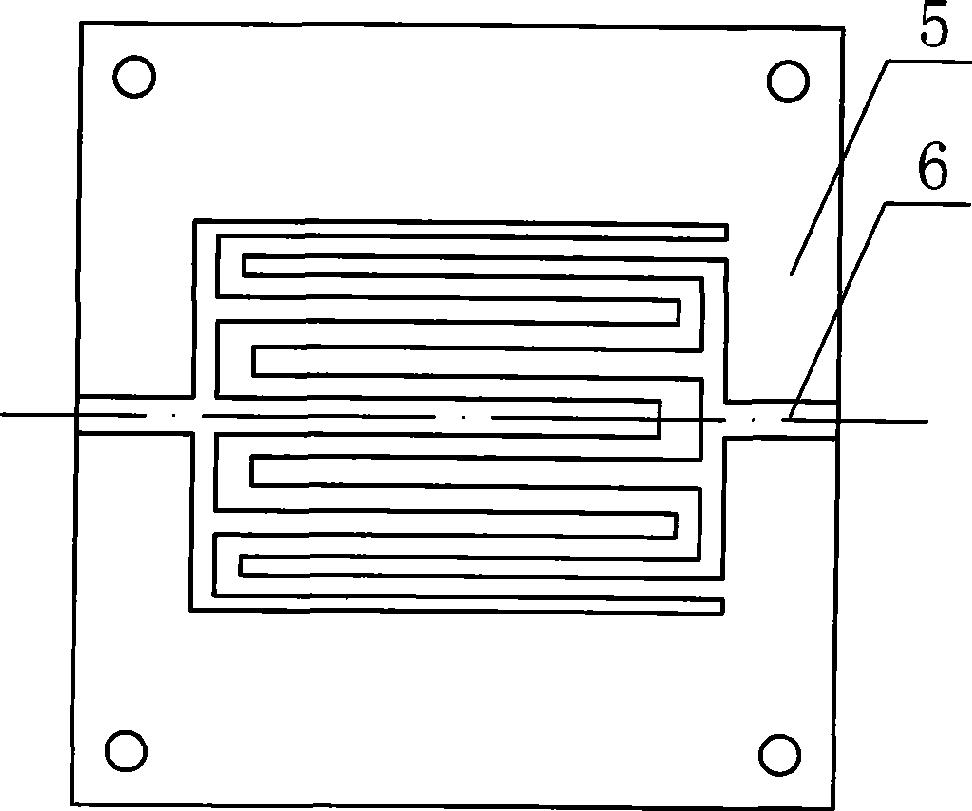

[0021] Interdigitated capacitance grain moisture content sensor, its composition comprises: base 1, described base connects cover plate 2, described base connects circuit board 3, described base two ends connect SMA connector 4, described circuit board is A polytetrafluoroethylene substrate 5 with a dielectric constant of 2.2 is coated with a copper plating layer with a thickness of 0.017mm on the upper and lower surfaces of the substrate, and an interdigitated capacitor 6 is processed on the copper plating layer on the upper surface. The copper plating layer 7 on the lower surface exposes the substrate non-uniformly from the inside to the outside, and the exposed shape is a square 8 .

Embodiment 2

[0023] Interdigitated capacitance grain moisture content sensor, its composition comprises: base 1, described base connects cover plate 2, described base connects circuit board 3, described base two ends connect SMA connector 4, described circuit board is A polytetrafluoroethylene substrate 5 with a dielectric constant of 2.2 is coated with a copper plating layer with a thickness of 0.017mm on the upper and lower surfaces of the substrate, and an interdigitated capacitor 6 is processed on the copper plating layer on the upper surface. The copper plating layer 7 on the lower surface exposes the substrate non-uniformly from the inside to the outside, and the exposed shape is a square 8 .

[0024] In the interdigitated capacitance grain moisture sensor, the base is made of copper or aluminum, the inner surface is plated with gold, the surface roughness is Ra<160, and Rz<6.3.

[0025] For the interdigitated capacitance grain moisture content sensor, the cover plate is made of poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| impedance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com