Mutton sausage and preparation method thereof

A technology of sausage and mutton, applied in food preparation, application, food science, etc., to achieve the effect of good palatability and rich varieties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The formula of the mutton sausage of this embodiment:

[0027] Lamb foreleg 80Kg

[0028] 10Kg of vegetable oil, including 8Kg of vegetable blended oil and 2Kg of sesame oil

[0029] Water 10Kg

[0030] Salt 2.0Kg

[0031] Nitrite 0.008Kg

[0032] Tripolyphosphate 0.3Kg

[0033] Sodium Erythorbate 0.3Kg

[0034] Koji wine 2.5Kg

[0035] White sugar 1.0Kg

[0036] MSG 0.3Kg

[0037] Spices 1.0Kg, including onion juice 0.9Kg, ginger powder 0.1Kg

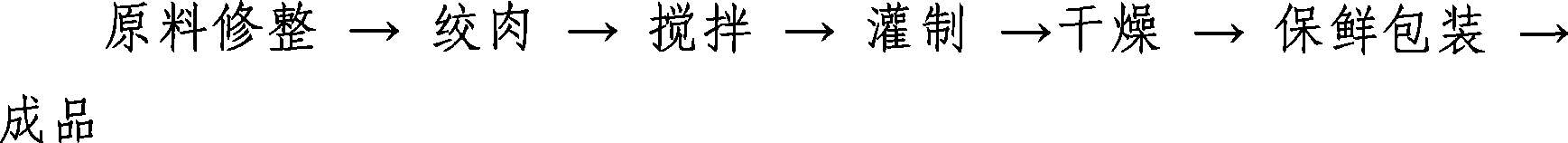

[0038] Such as figure 1 Shown, the preparation method of the mutton sausage of the present embodiment comprises the steps:

[0039] (1) Take the lamb foreleg meat, remove fascia, blood stains, grease, wounded meat and other foreign objects, cut into long strips, then twist to make meat stuffing, add 3Kg of water, add salt and nitrite, stir evenly, and put it at 2°C Marinated in the pickling room for 35 hours;

[0040] (2) Heat the vegetable oil to 160° C., add spices during the heating process of the vegetable oil, a...

Embodiment 2

[0050] The formula of the mutton sausage of this embodiment:

[0051] Lamb Shoulder 70Kg

[0052] Flower oil 15Kg

[0053] Water 5Kg

[0054] Salt 1.5Kg

[0055] Nitrite 0.01Kg

[0056] Tripolyphosphate 0.1Kg

[0057] Sodium Erythorbate 0.1Kg

[0058] Koji wine 1.2Kg

[0059] White sugar 2.0Kg

[0060] MSG 0.5Kg

[0061] Spices 0.05Kg, including spicy oil 0.02Kg, cumin 0.01Kg, white pepper 0.02Kg.

[0062] The preparation method of the mutton sausage of the present embodiment comprises the steps:

[0063] (1) Grind the mutton shoulder to make meat stuffing, add 2.5Kg of water, add salt and nitrite, stir evenly, and put it in the pickling room at 0°C for 48 hours;

[0064] (2) The step of heating vegetable oil to 140°C. Put the spices into the vegetable oil heating process, and filter out the spices after the spices smell into the vegetable oil.

[0065] (3) Take the marinated mutton stuffing, add 2.5Kg of water, add tripolyphosphate, fully stir until mixed evenly, ...

Embodiment 3

[0070] The formula of the mutton sausage of this embodiment:

[0071] Lamb foreleg 72Kg

[0072] Vegetable oil 20Kg, including corn salad oil 16.5Kg, sesame oil 3.5Kg

[0073] water 2Kg

[0074] Salt 2.5Kg

[0075] Nitrite 0.003Kg

[0076] Tripolyphosphate 0.5Kg

[0077] Sodium Erythorbate 0.6Kg

[0078] White sugar 0.1Kg

[0079] MSG 0.1Kg

[0080] Spices 1.5Kg, including spicy oil 0.8Kg, cumin 0.3Kg, white pepper 0.2Kg, coriander powder 0.2Kg

[0081] The preparation method of the mutton sausage of the present embodiment comprises the steps:

[0082] (1) Grind lamb foreleg meat to make meat filling, add 0.8Kg of water, add salt and nitrite, stir evenly, put it in a curing room at 4°C for 24 hours;

[0083] (2) Heat the vegetable oil to 180° C., add spices during the heating process of the vegetable oil, and filter out the spices after the spices smell into the vegetable oil.

[0084] (3) Take the marinated mutton filling, add 1.2Kg of water, add tripolyphosphate, sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com