Austenitic stainless steel welded joint and austenitic stainless steel welding material

An austenitic, welded joint technology used in welding/welding/cutting items, welding/cutting media/materials, welding media, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

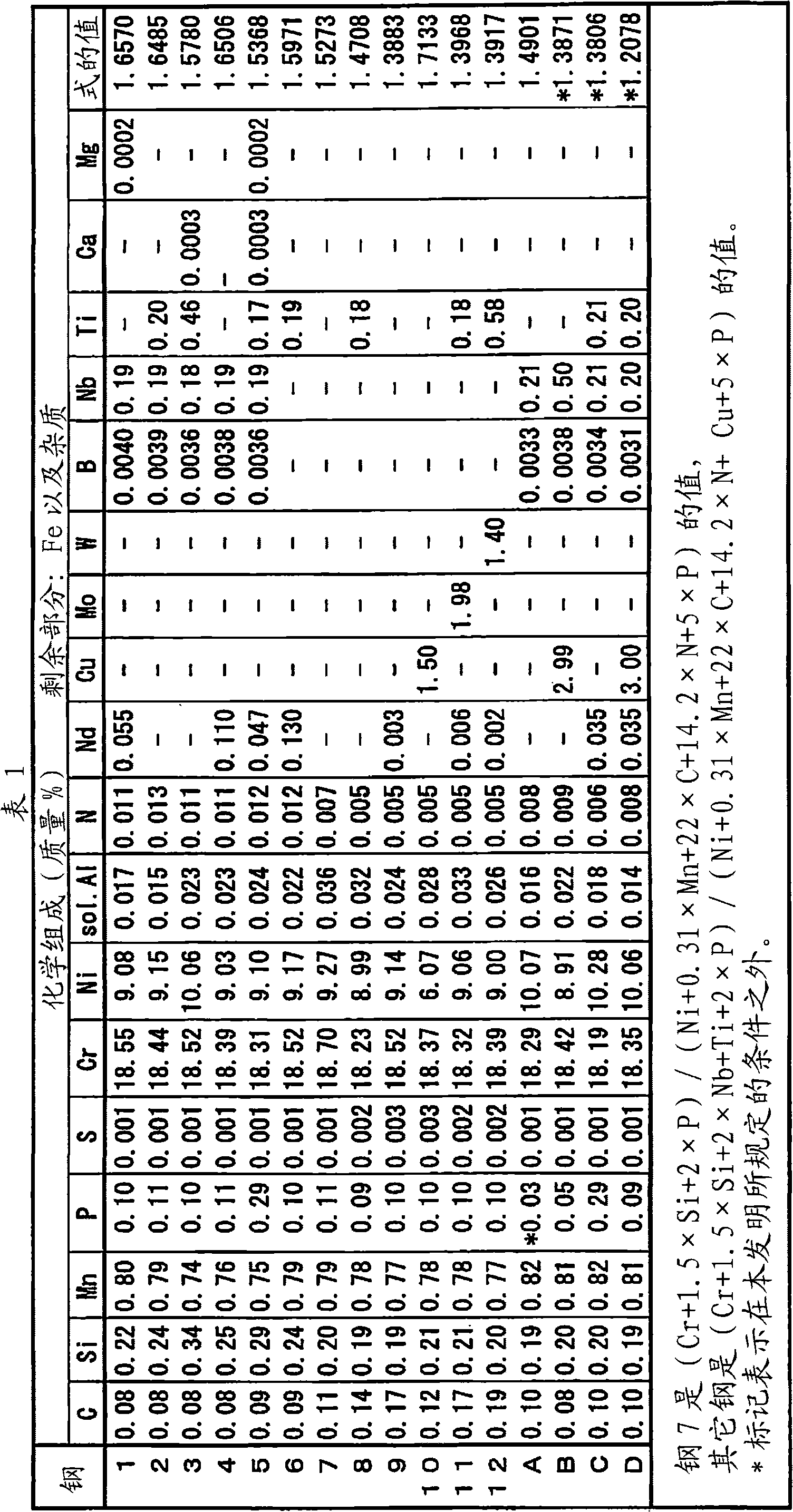

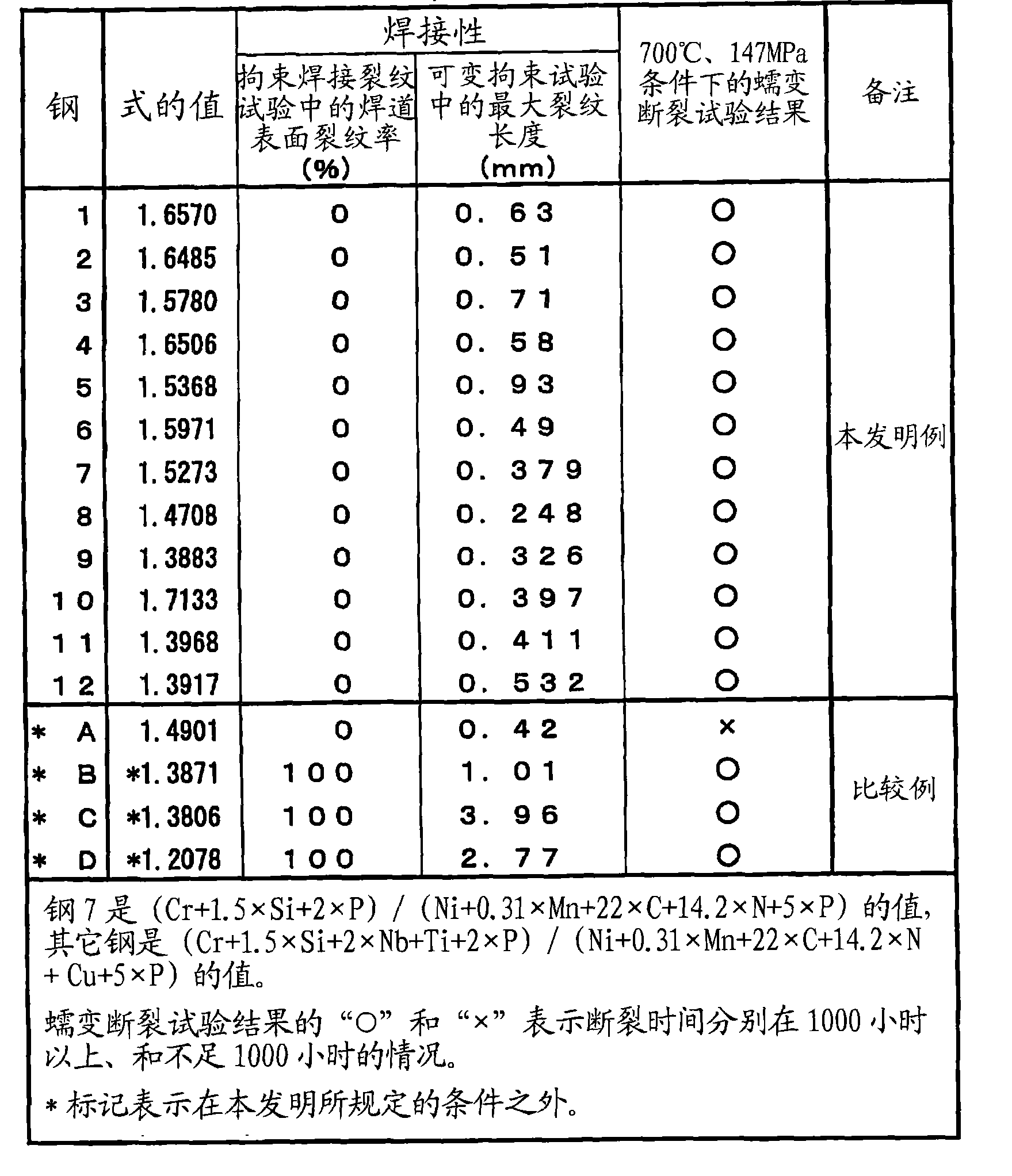

[0122] Steels 1 to 12 and steels A to D, which are austenitic stainless steels having the chemical compositions shown in Table 1, were melted in a high-frequency heating vacuum furnace, and cast into steel ingots.

[0123] Steels 1 to 12 in Table 1 are steels whose chemical compositions are within the range specified by the present invention. On the other hand, steels A to D in Table 1 are steels of comparative examples whose chemical compositions are outside the conditions specified in the present invention.

[0124] In addition, in austenitic stainless steel tubes used for heat exchange in boilers, the content of P is limited to 0.040% or less as stipulated in JIS G3463. Therefore, 0.03% of the P content of Steel A in Table 1 corresponds to the P content of common austenitic stainless steel used for boiler heat exchange.

[0125] Table 1

[0126]

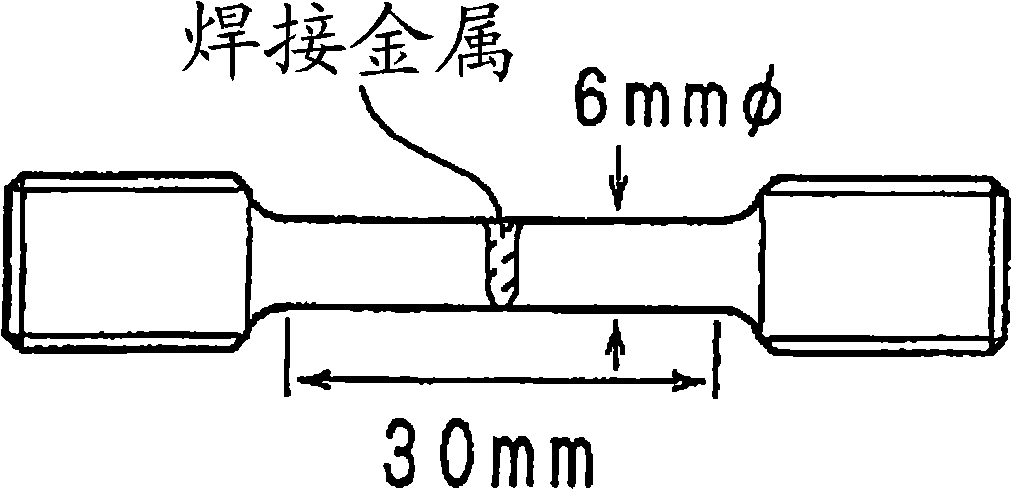

[0127] After hot forging each steel ingot obtained by the usual method, solution heat treatment was performed at 1200°C, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com