Resin composition for optical material and optical material using the same

A resin composition and optical material technology, applied in the field of optical materials, can solve the problems of reduced heat resistance, difficulty in realization, lack of practicability of lenses, etc., and achieve the effect of high strength and high heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

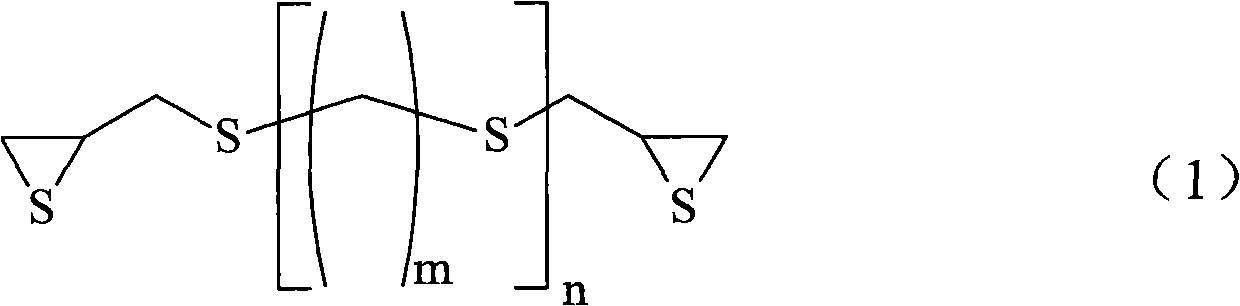

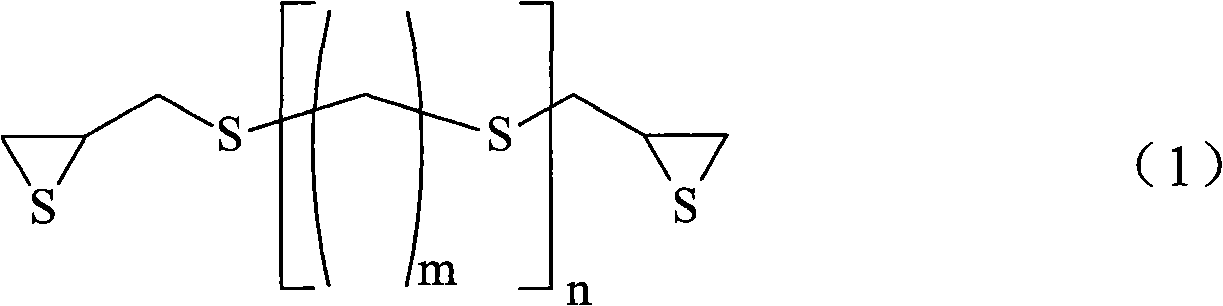

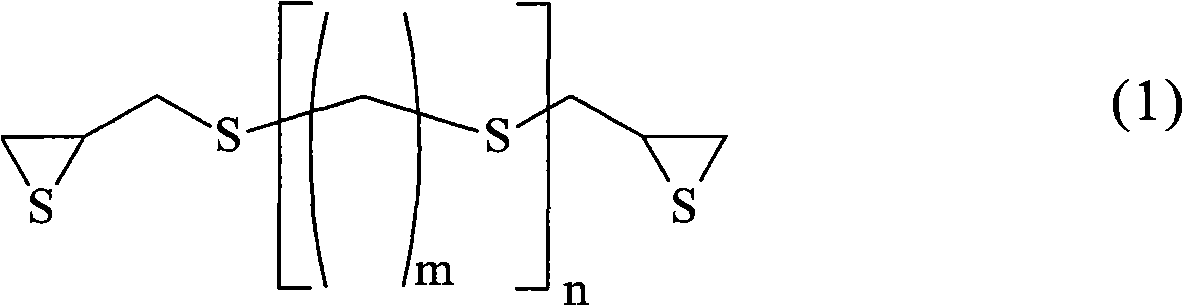

Method used

Image

Examples

Embodiment 1

[0077] Mix (a) 67 parts by weight of bis(β-epithiopropyl) sulfide as an episulfide compound, (b) 16 parts by weight of m-xylylenedithiol as a xylylenedithiol compound, ( c) 17 parts by weight of 1,3-bis(1-isocyanate-1-methylethyl)benzene as a xylylene diisocyanate compound, 0.005 parts by weight of polyoxyethylene lauryl ether sodium phosphate as an internal release agent Parts by weight, 0.05 parts by weight of dibutyltin dichloride as a polymerization regulator, 0.1 parts by weight of tetrabutylphosphonium bromide as a polymerization catalyst, 0.005 parts by weight of catechol as an antioxidant, and 0.005 parts by weight of catechol as an antioxidant, and as an ultraviolet absorber 0.5 parts by weight of 2-(2-hydroxy-5-tert-octylphenyl)benzotriazole was stirred at room temperature to form a homogeneous liquid. Next, the above-mentioned composition was degassed for 30 minutes under a reduced pressure of 10 Torr, and then poured into a lens mold, and the temperature was raised...

Embodiment 2~6

[0079] Carry out the operation of embodiment 1 by the composition shown in table 1. The obtained lenses were all transparent and had good appearance. Optical physical properties, strength, and heat resistance were measured, and the results are shown in Table 1.

Embodiment 7~14

[0081] As shown in Table 1, when the composition of (d) a compound containing both ester groups and mercapto groups was used in combination, the obtained lenses were all transparent and had a good appearance. Optical physical properties, strength, and heat resistance were measured, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com