Method for manufacturing special cable of wind power plant

A technology for wind power generation equipment and special cables, which is applied in the manufacture of cables/conductors, insulation of conductors/cables, circuits, etc., can solve the problems of poor product quality stability, high labor intensity of operators, and high requirements for employee quality, and achieve product quality. The effects of poor stability, high employee quality requirements, and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

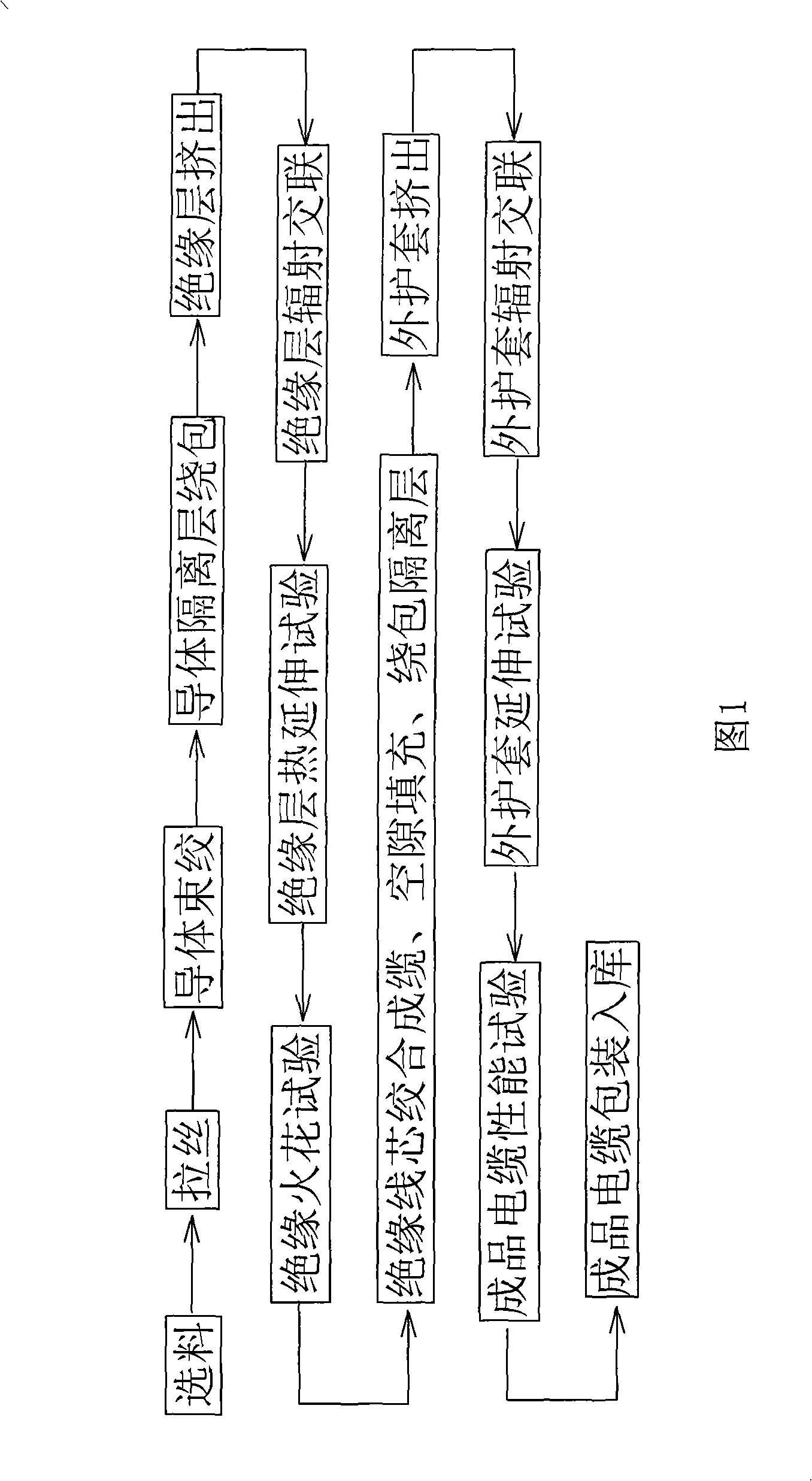

[0031] Embodiment: Referring to the accompanying drawings, the manufacturing method of the special cable for wind power generation equipment in this embodiment, its manufacturing steps are as follows: material selection - wire drawing - conductor bundle stranding - isolation layer wrapping - insulation layer extrusion - insulation layer radiation crosslinking - insulation Wire core twisted into cable, gap filled and wrapped with isolation layer-outer sheath extrusion-outer sheath radiation cross-linking-finished product inspection-finished product;

[0032] The material selection is based on the performance requirements of the product, and formulates its procurement specifications and acceptance requirements for various materials required.

[0033] Extrusion of the insulating layer: using a semi-extrusion die, carried out on an ordinary extruder with a screw length-to-diameter ratio of 20:1 or 25:1 and a compression ratio of 2.5:1 or 2.0:1, extruding on the conductor isolation la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com