Compact roller drawing frame and spinning machine including same

A technology for drawing frames and spinning machines, applied in spinning machines, textiles, papermaking, drafting equipment, etc., can solve problems such as too large coverage area, and achieve the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

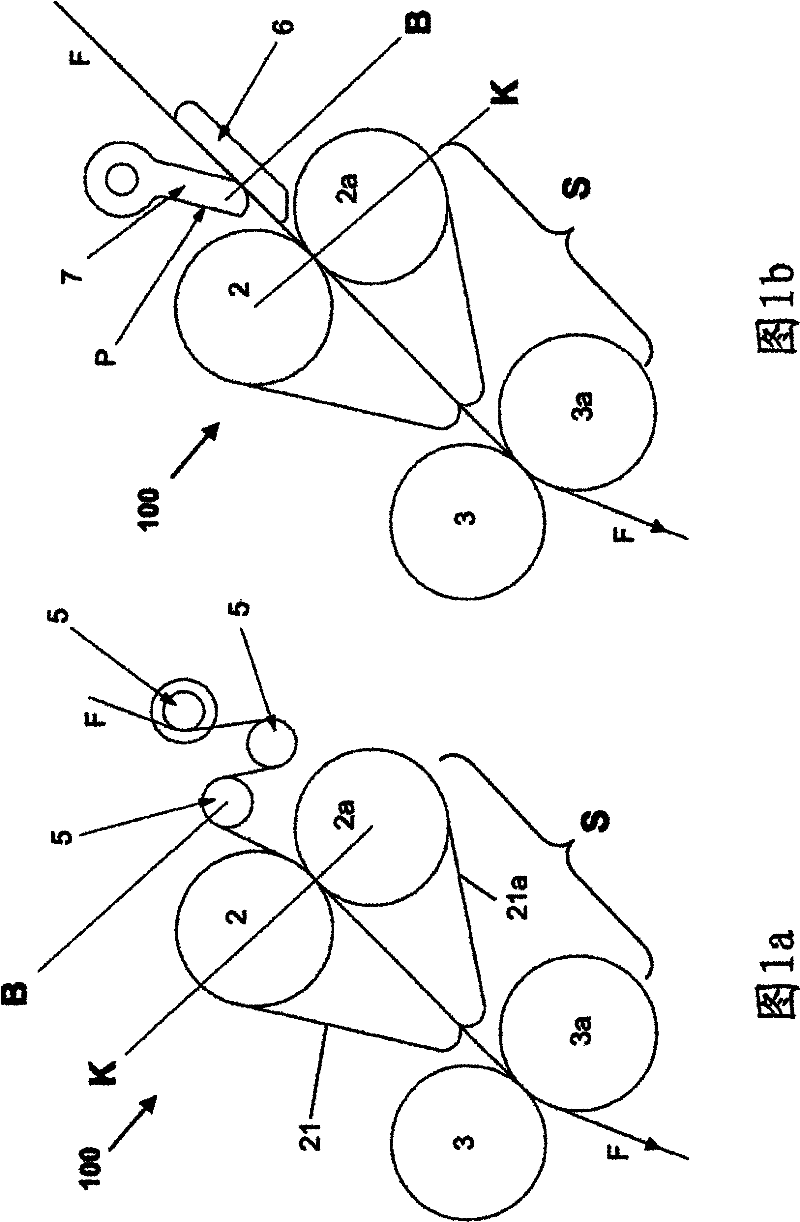

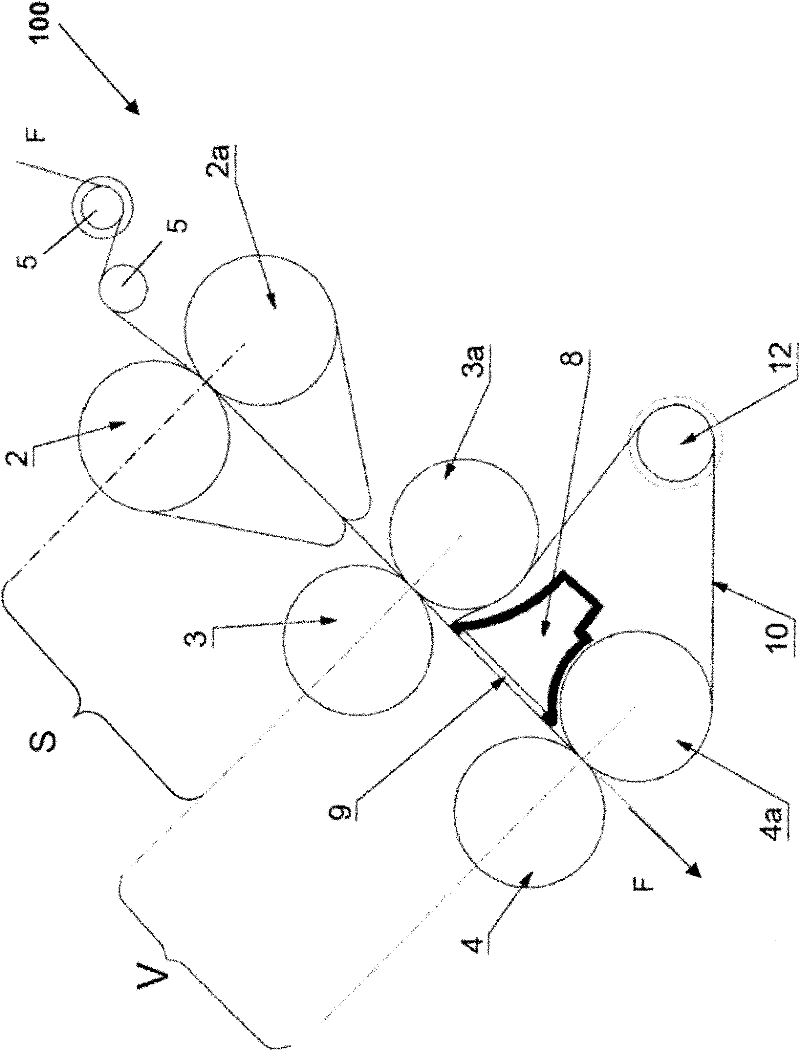

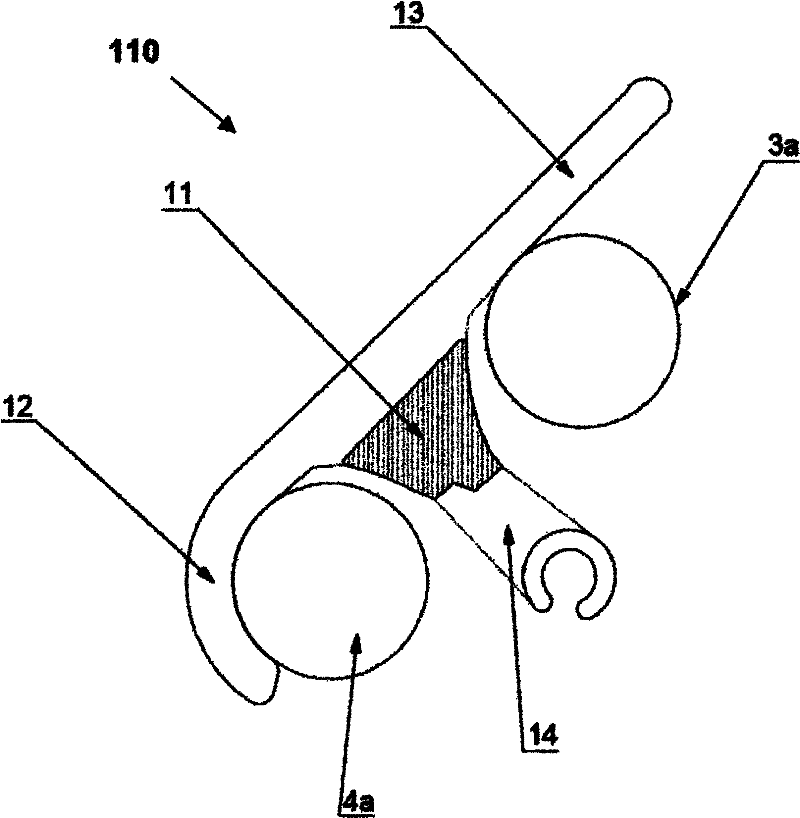

[0032] It should be understood that components having the same and / or similar functions are identified with similar reference numerals in the figures.

[0033] see now Figure 1a, shows a diagrammatic side view of a first embodiment of a roller draw frame 100 according to the invention showing the passage of a single spinning position, ie a single sliver F in the direction indicated by the arrows. The roll draw frame 100 comprises an input roll pair 2 / 2a and an output roll pair 3 / 3a forming a drafting zone S, between which the overall drafting of the sliver F is effected. The input roller pair 2 / 2a is wound by a drafting belt 21 / 21a (top belt / bottom belt) extending into the drafting zone S.

[0034] No pre-drawing zone is provided as in the prior art. Just before entering the drafting zone S, the sliver F supplied for compaction is lightly tensioned by a braking device having, for example, three sheaves 5 . The desired pre-stretching is achieved by the winding friction betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com