Construction body with thermal insulation and construction method

A construction method and technology of thermal insulation layer, applied in thermal insulation, building components, etc., can solve problems such as short service life, easy aging or carbonization, and reduced thermal insulation performance, and achieve good deformation adaptability, excellent air permeability, and long-term waterproof performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

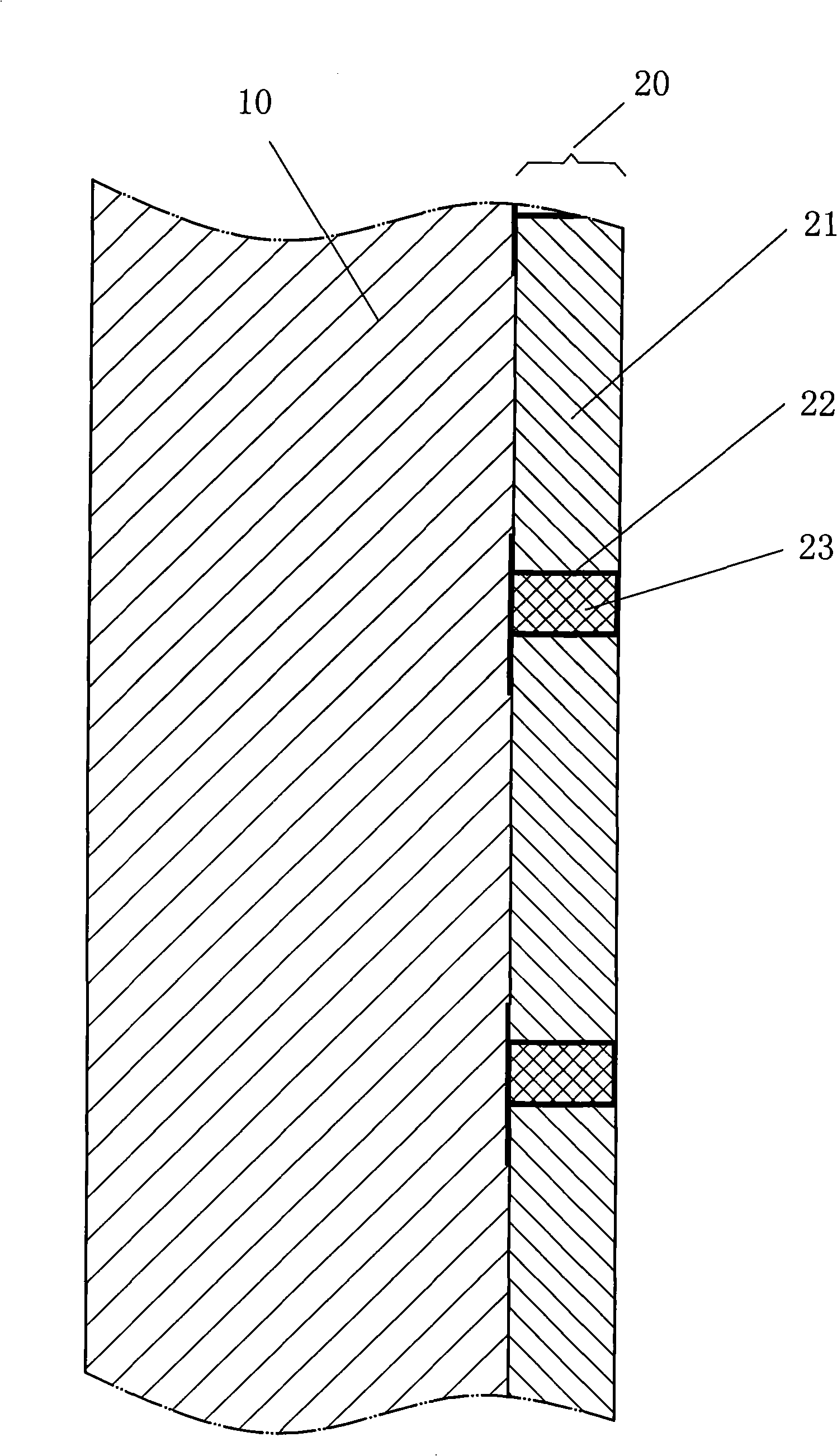

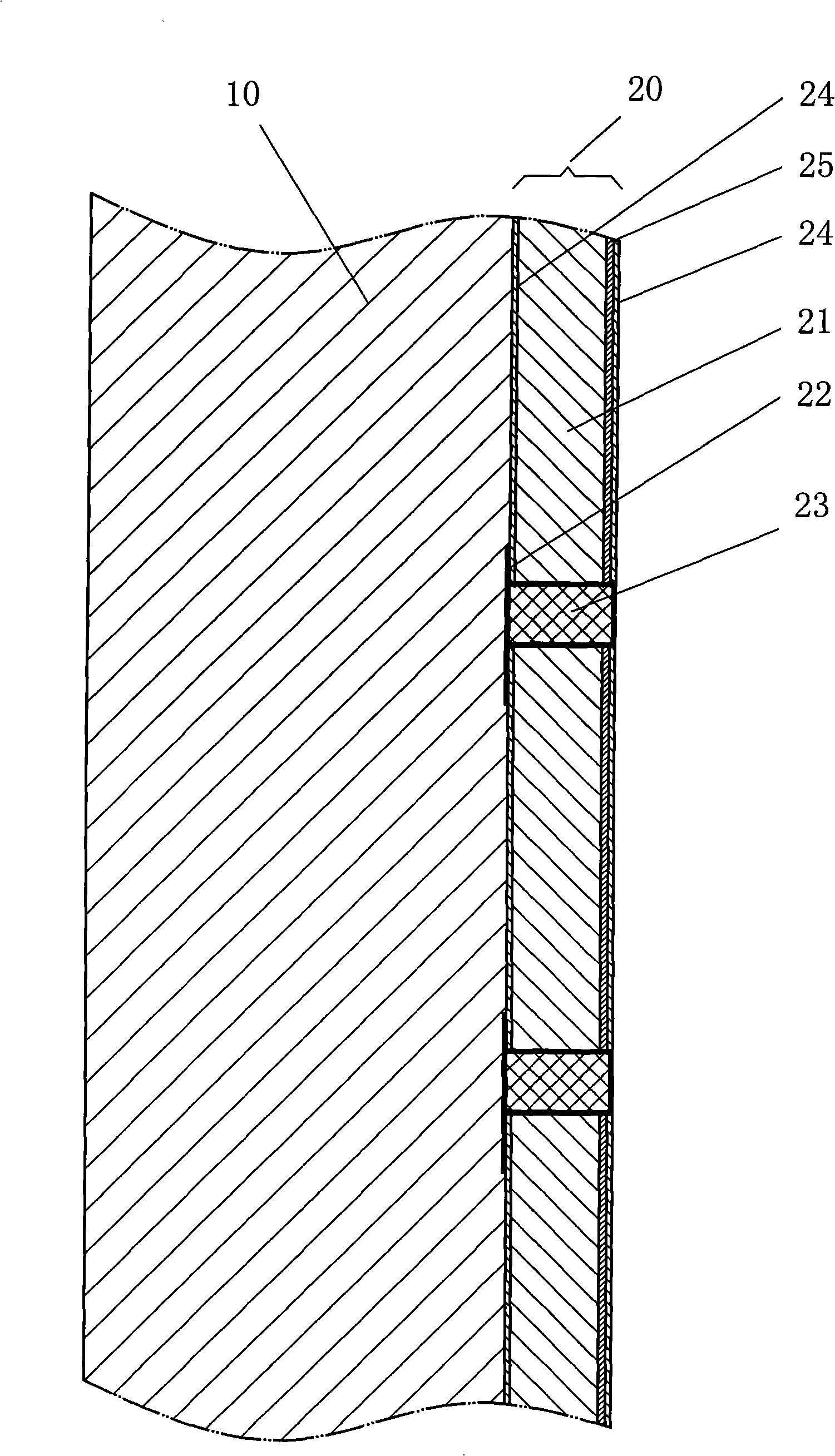

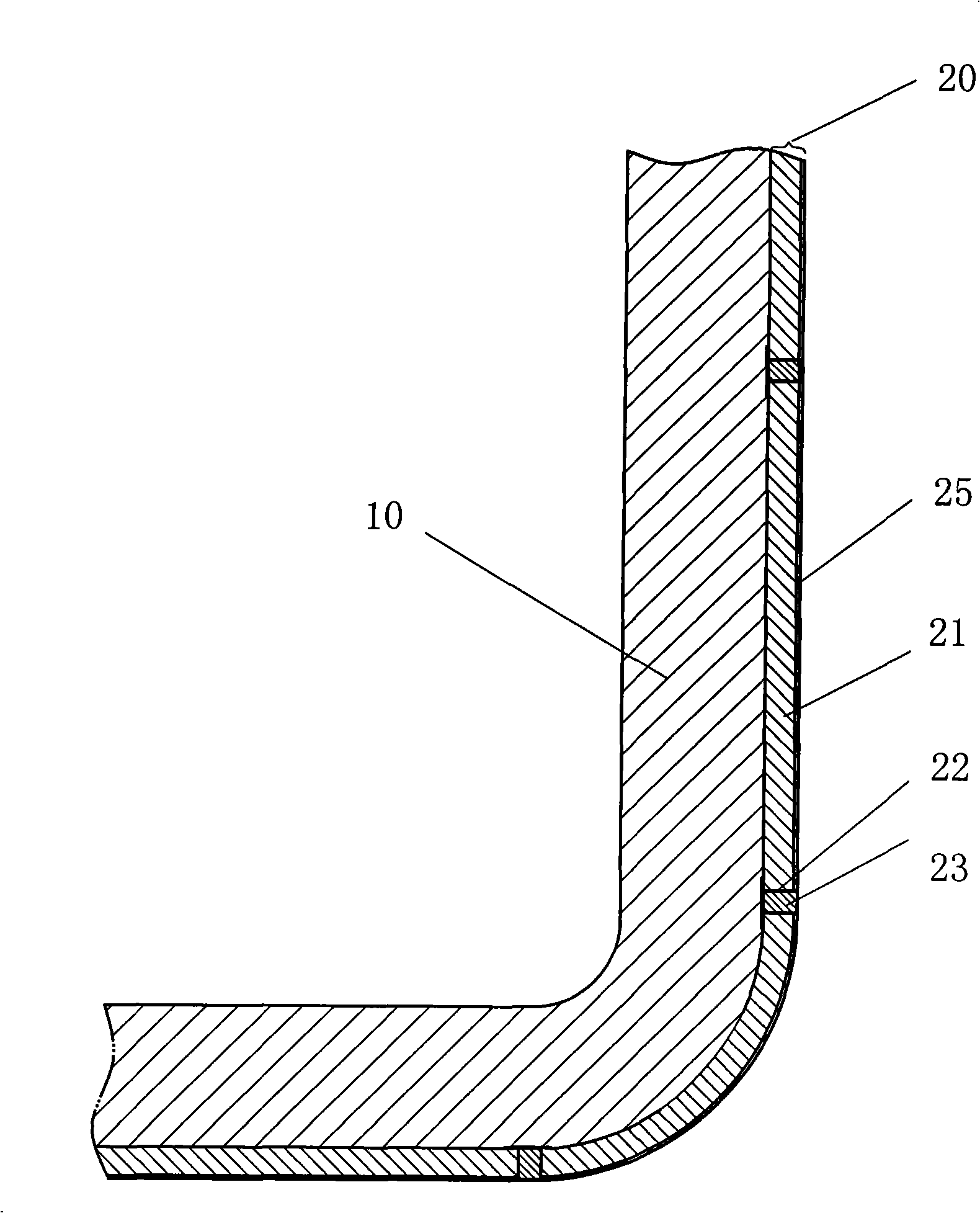

[0024] The present invention will be further described below with specific embodiment, see Figure 1-3 :

[0025] For a building with an insulating layer, a layer of insulating layer 20 is provided on the outer surface of the beam or column of the building or the wall base 10. The insulating layer 20 includes insulating boards 21 arranged at intervals in the vertical and horizontal directions, and flexible or elastic insulating tapes. 23 and positioning piece 22.

[0026] The above-mentioned insulation board 21 may be one or a combination of insulation boards of the same material, insulation boards of multiple materials, insulation boards with protective and / or decorative layers, and insulation boards with positioning pieces.

[0027] The above insulation boards of the same material refer to foam concrete insulation boards of the same material.

[0028] The above-mentioned foamed concrete insulation board of the same material has a sealed reinforced waterproof layer 24 forme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com