Rubber plastic material for producing shoe pad, shoe pad and manufacturing method thereof

A technology of rubber, plastic and insoles, which is applied in the field of rubber and plastic materials, and can solve the problems of user inconvenience, loss of elasticity, and reduced shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

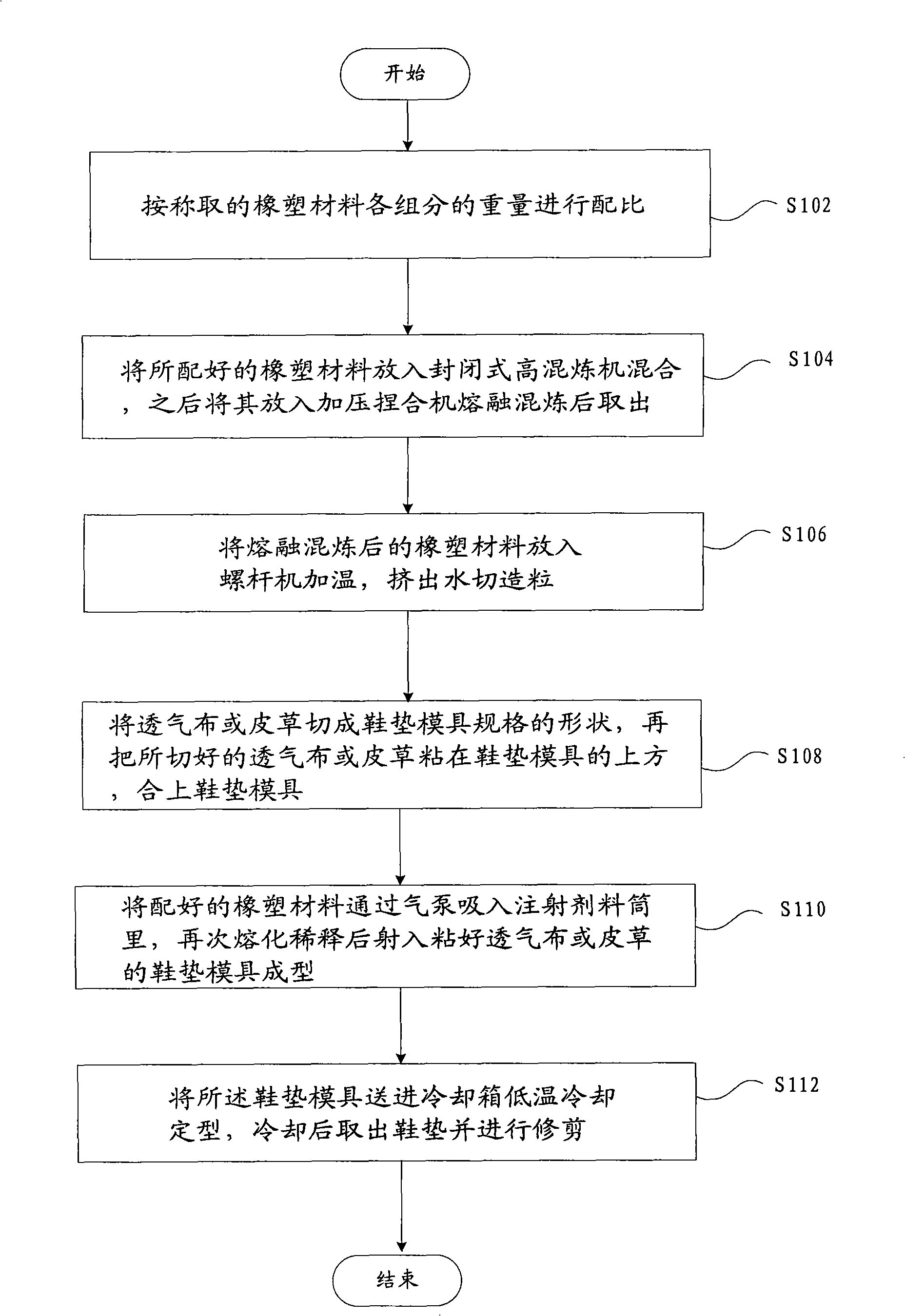

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

[0026] According to an embodiment of the present invention, the rubber and plastic material for making insoles includes: a copolymer of high molecular weight styrene (S)-ethylene (E) and butene (B)-styrene (S) blocks Type A SEBS, copolymer of medium molecular weight styrene (S)-ethylene (E) and butene (B)-styrene (S) blocks, type B SEBS, plasticizer, polyurethane, compatibilizer, anti- Oxygen, inorganic minerals.

[0027] In this embodiment, the above-mentioned rubber and plastic materials are used to make insoles. Since SEBS combines the thermoplastic characteristics of polystyrene and the elastomeric characteristics of ethylene-butylene copolymer in the same polymer, its molecular configuration is a three-block A-B-A type. Copolymer, SEBS with such a three-block configuration shows in basic performance characteristics: the polysty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com