Commutator production process

A manufacturing method and commutator technology, applied in commutator manufacturing and other directions, can solve the problems of residual mica in the insulating groove, inconsistent tightness of the sheet ring, and excessive wear of the carbon brush, so as to save the mechanical processing steps and the processing process. Simple, easy-to-manufacture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

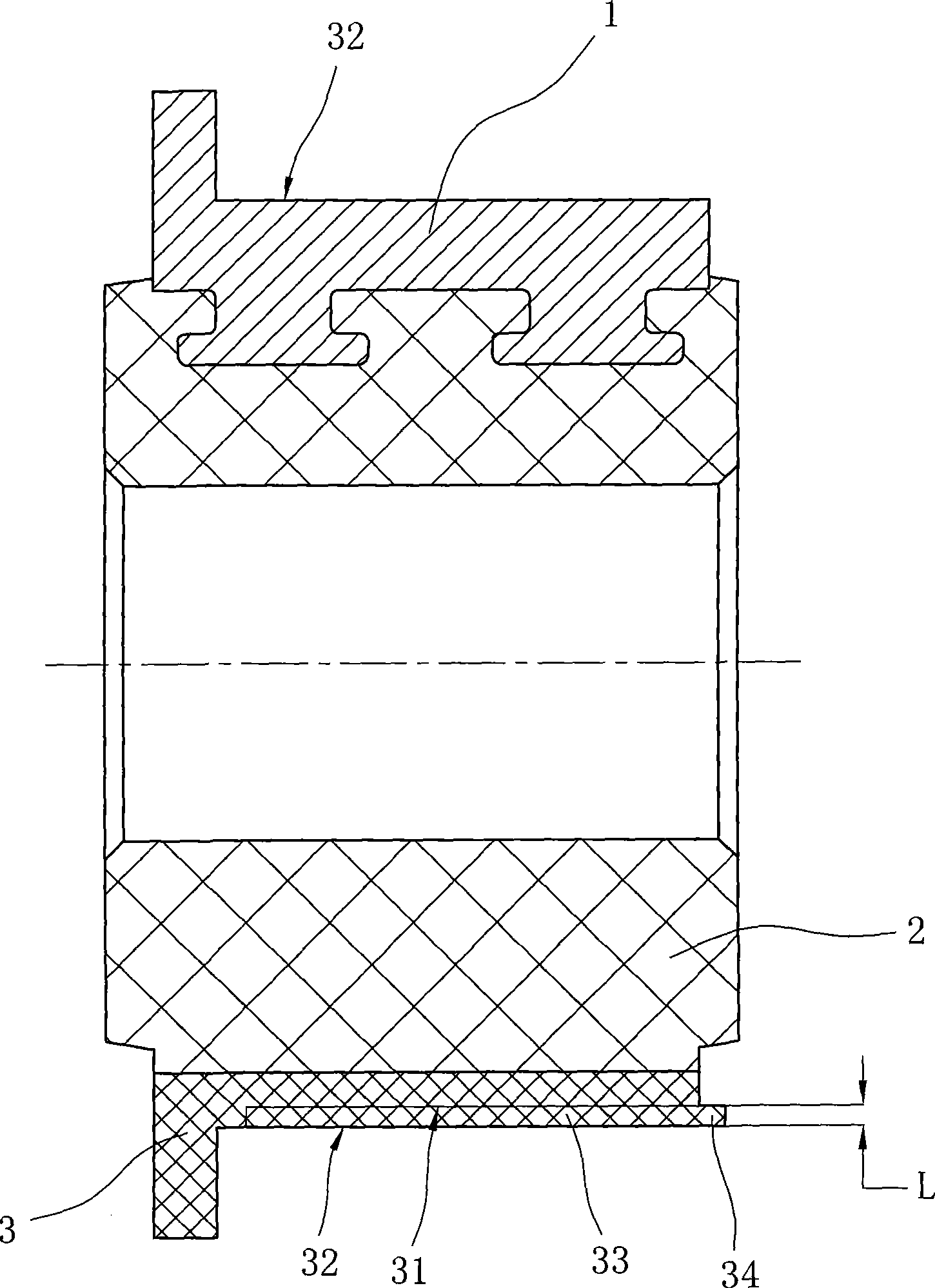

[0026] figure 1 Shown is a cross-sectional view of the commutator structure of the embodiment of the present invention. The commutator is a slot-type commutator, including a plurality of commutator segments 1 spaced apart from each other, and a base 2 for fixing the commutator segments, wherein adjacent commutator segments 1 pass through mica sheets 3 Insulation grooves are spaced apart and formed, and the base body 2 is injection-molded with engineering plastics.

[0027] The commutator of this embodiment is realized through the following process steps:

[0028] [1], using copper as raw material, blanking and drawing into copper bars;

[0029] [2] Punch commutator segments on the copper bar;

[0030] [3], cleaning the punched commutator segment 1;

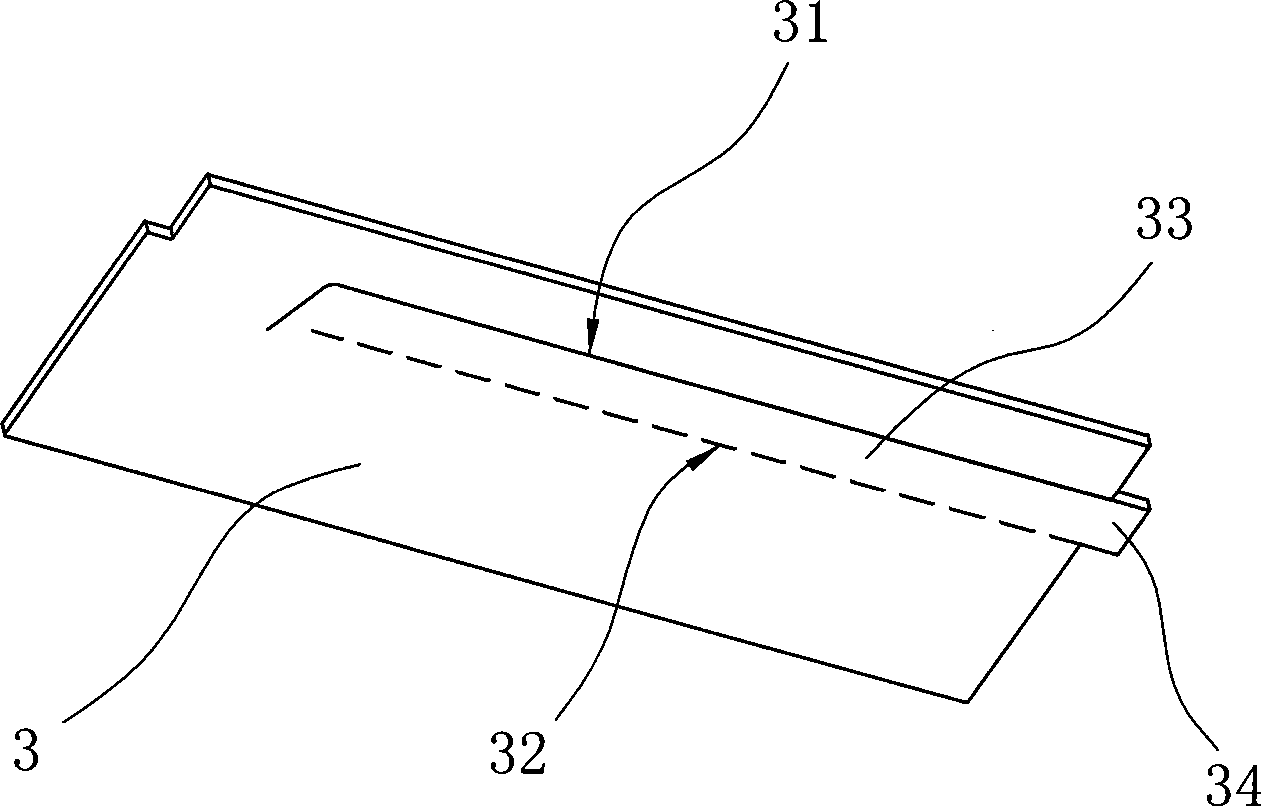

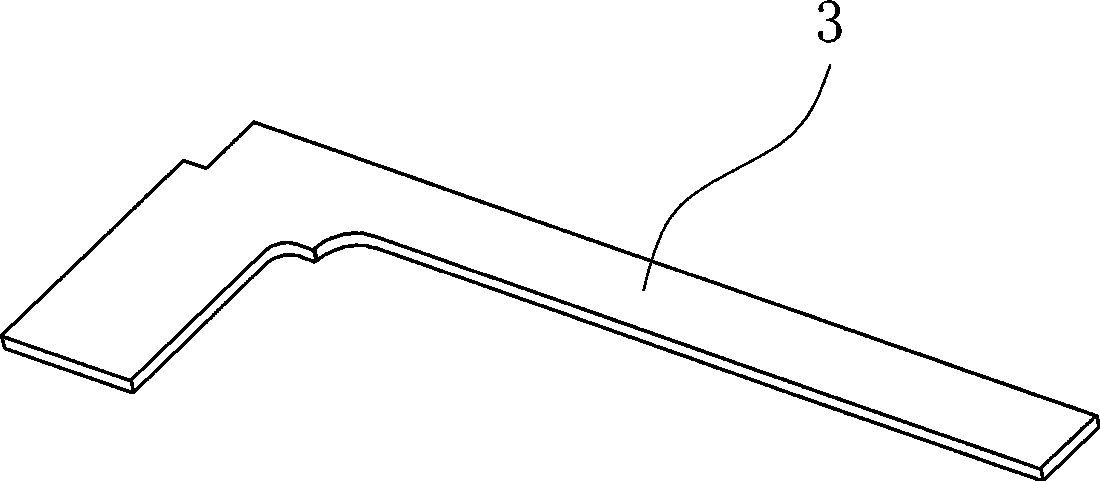

[0031] [4], the mica sheet 3 is cut into strips and punched into shape, and a breakable n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com