Plastic-coated magnet and manufacturing method thereof

A technology of encapsulation and magnets, which is applied in the direction of magnets, inductors/transformers/magnets, magnetic objects, etc., can solve problems such as complex procedures and waste of plastic materials, and achieve the goals of saving encapsulation materials, improving reliability, and reducing manufacturing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with test example and specific embodiment, but this should not be interpreted as the scope of the above-mentioned theme of the present invention being limited to the following examples, all technologies realized based on the content of the present invention all belong to the present invention scope.

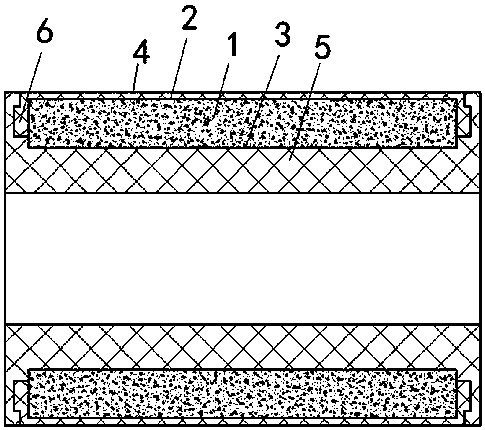

[0033] A encapsulated magnet, such as figure 1 As shown: it includes a magnet 1 and a coating layer coated on the outside of the magnet 1, the magnet 1 includes a magnetic working area 2 and an assembly area 3, and the magnetic working area 2 is covered with a first coating layer 4, so The assembly area 3 is covered with a second rubber coating layer 5, the first rubber coating layer 4 and the second rubber coating layer 5 are sealed and fit, and the injection molding fluidity of the material of the first rubber coating layer 4 is greater than Injection fluidity of the material of the second en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com