Double-functional manual biogas liquid residue discharge pump

A discharge pump, dual-function technology, applied in the field of manual biogas residue and biogas liquid discharge pump, can solve the problems of slow discharge speed, low discharge pressure, low discharge efficiency, etc. The effect of high pressure and high discharge efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

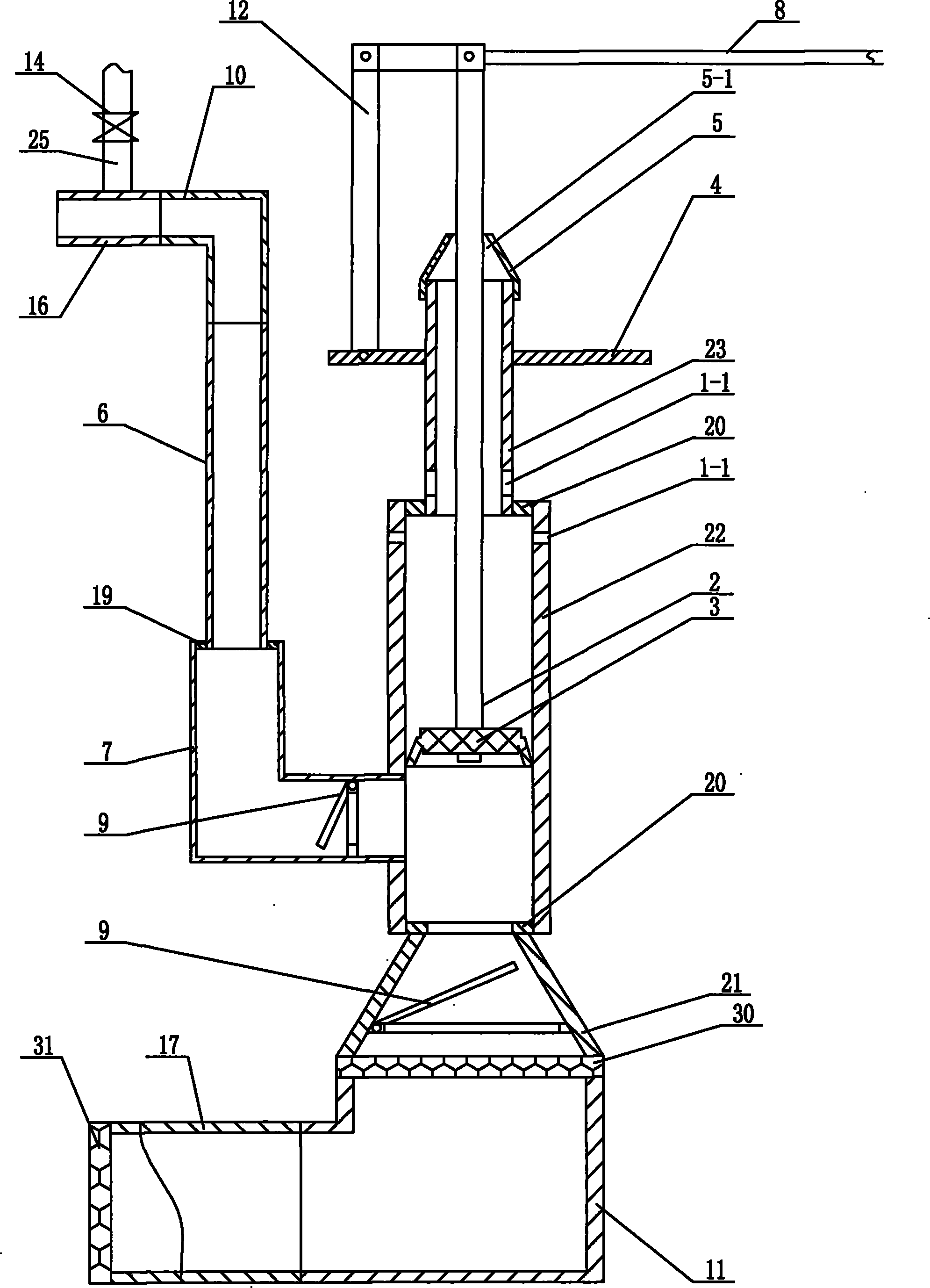

[0007] Specific implementation mode one: combine figure 1 Describe this embodiment, this embodiment includes a cylinder liner, a pull rod 2, a piston 3, a fastening plate 4, a reducer 5, a first elbow 7, a second elbow 10, a hand lever 8, two switches 9, Backwash pipe 6, hinge 12, valve 14, discharge pipe 16, second connector 19 and water inlet pipe 25, the large-diameter end of the reducer pipe 5 is threadedly connected to the upper end of the sheath support pipe 23 of the cylinder liner , the lower end of the pull rod 2 passes through the inner hole 5-1 of the reducer 5 and is installed in the piston working tube 22 of the cylinder liner, the lower end of the pull rod 2 is equipped with a piston 3, and the upper end of the pull rod 2 is connected with the hand pressure rod 8 One end of the hinge 12 and one end of the hinge 12 are hinged together, and the other end of the hinge 12 is hinged with the fastening plate 4, and the fastening plate 4 is fixed on the outer wall of th...

specific Embodiment approach 2

[0008] Specific implementation mode two: combination figure 1 To illustrate this embodiment, the cylinder liner of this embodiment is composed of a sheath support tube 23, a piston working tube 22, a connecting tube 21 and two first connectors 20, and the upper end surface and the lower end surface of the piston working tube 22 respectively pass through A first connecting piece 20 is connected with the lower end surface of the sheath support pipe 23 and the upper end surface of the connecting pipe 21 . So set, easy to install. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0009] Specific implementation mode three: combination figure 1 The present embodiment will be described. The longitudinal section of the connecting pipe 21 of the cylinder liner of the present embodiment is trapezoidal. With such setting, the discharging speed is faster and the discharging efficiency is higher. Other compositions and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com