Production method of anti-interference paper intensifier

A paper strengthening agent and initiator technology, which is applied in the field of polymer compound preparation, can solve the problems of reducing the performance of ordinary paper strengthening agents, the molecular chain structure is prone to breakage, and the product has a single variety of functional groups, achieving significant retention and drainage. Effect, enhanced retention and drainage effect, good fluidity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

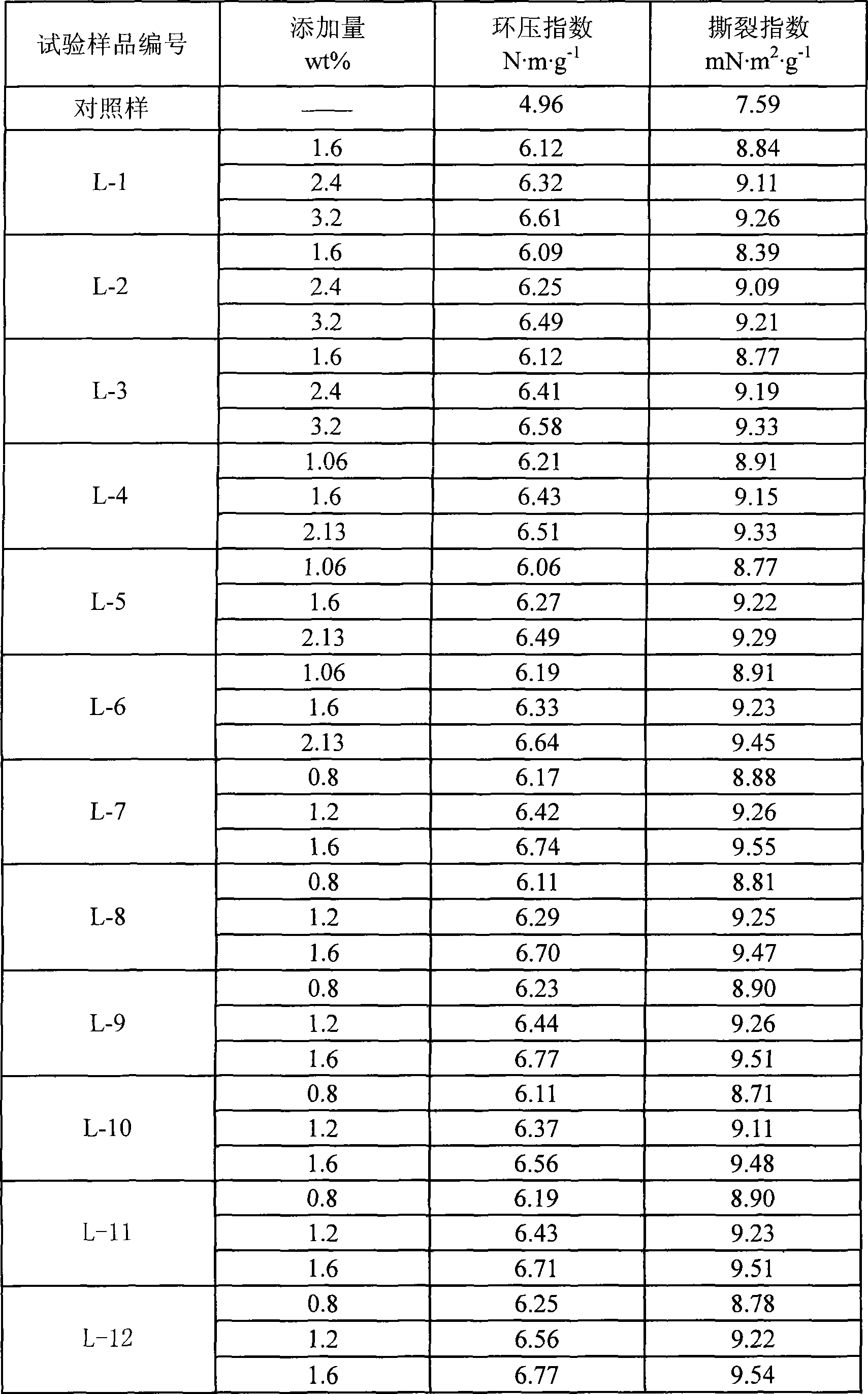

Examples

Embodiment 1

[0033] Add 950g of pure water into the four-neck flask, start stirring, and then add 85.0g (1.2mol) of acrylamide, 3.5g (0.0486mol) of acrylic acid, 18.6g (0.090mol) of methacryloyloxyethyltrimethylammonium chloride ), 4.2g (0.018mol) of sodium 2-acrylamide-2-methylpropanesulfonate, adjust the pH to 4.0, then pass nitrogen to remove oxygen, and simultaneously raise the temperature of the reaction system to 55°C, and then sequentially add a mass concentration of 1% 9.6g of N,N-methylenebisacrylamide aqueous solution, 13.8g of 10% sodium methallyl sulfonate aqueous solution and 3.5g of 10% ammonium persulfate aqueous solution are used to initiate polymerization, and the reaction releases Heat, the temperature rises to 90°C, and after the polymerization reaction is carried out for 20 minutes, add 7.5 g of 2,2-azo-bis(2-amidinopropane) hydrochloride aqueous solution with a mass concentration of 10%, keep it warm, and keep it at 85°C for 30 minutes. , Add 60 g of sodium sulfite aqu...

Embodiment 2

[0035] Add 950g of pure water into the four-neck flask, start stirring, and then add 85.0g (1.2mol) of acrylamide, 5.8g (0.081mol) of acrylic acid, 14.3g (0.091mol) of dimethylaminoethyl methacrylate, 2- 5.2g (0.023mol) of sodium acrylamide-2-methylpropanesulfonate, adjust the pH to 4.5, then pass nitrogen to remove oxygen, and at the same time raise the temperature of the reaction system to 55°C, and then add vinyl toluene with a mass concentration of 1% in sequence 13.5 g of aqueous solution, 7.6 g of mercaptoethanol aqueous solution with a mass concentration of 10%, and 4.2 g of ammonium persulfate aqueous solution with a mass concentration of 10%, initiate polymerization, the reaction exotherms, the temperature rises to 96 ° C, and the polymerization reaction is carried out for 26 minutes. 10% 1-((cyano-1-methylethyl)azo)formamide aqueous solution 8.7g, keep warm, keep at 90°C for 60min, then add 60g of 10% sodium sulfite aqueous solution to terminate the reaction. A copol...

Embodiment 3

[0036]Add 950g of pure water into the four-neck flask, start stirring, and then add 85.0g (1.2mol) of acrylamide, 2.2g (0.031mol) of acrylic acid, 4.5g (0.035, 2.5%) of itaconic acid, dimethyl methacrylate 15.7g (0.1mol) of aminoethyl ester, 5.8g (0.025mol) of sodium 2-acrylamide-2-methylpropanesulfonate, adjust the pH to 5.0, then pass nitrogen to remove oxygen, and at the same time raise the temperature of the reaction system to 55°C, Then add successively the N that mass concentration is 1%, N-methylenebisacrylamide aqueous solution 10.5g, mass concentration are 10% sodium methallyl sulfonate aqueous solution 4.4g, mass concentration are 10% ammonium persulfate aqueous solution 5.2g, initiate polymerization, the reaction is exothermic, the temperature rises to 93 ° C, and after the polymerization reaction is stable for 35 minutes, add 11.6% of 2,2-azo-bis(2-amidinopropane) hydrochloride aqueous solution with a mass concentration of 10%. g, heat preservation, after keeping a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com