Method for preparing organic fertilizer by mixed fermentation of water hyacinth and dewatered sludge

A technology of dewatering sludge and mixed fermentation, which is applied in the preparation of organic fertilizers, organic fertilizers, urea compound fertilizers, etc., can solve the problems of environmental pollution, mildew of sludge, occupation of large land resources, etc., and solve the problem of non-point source pollution. , beneficial to the restoration of the environment, and the effect of promoting water treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

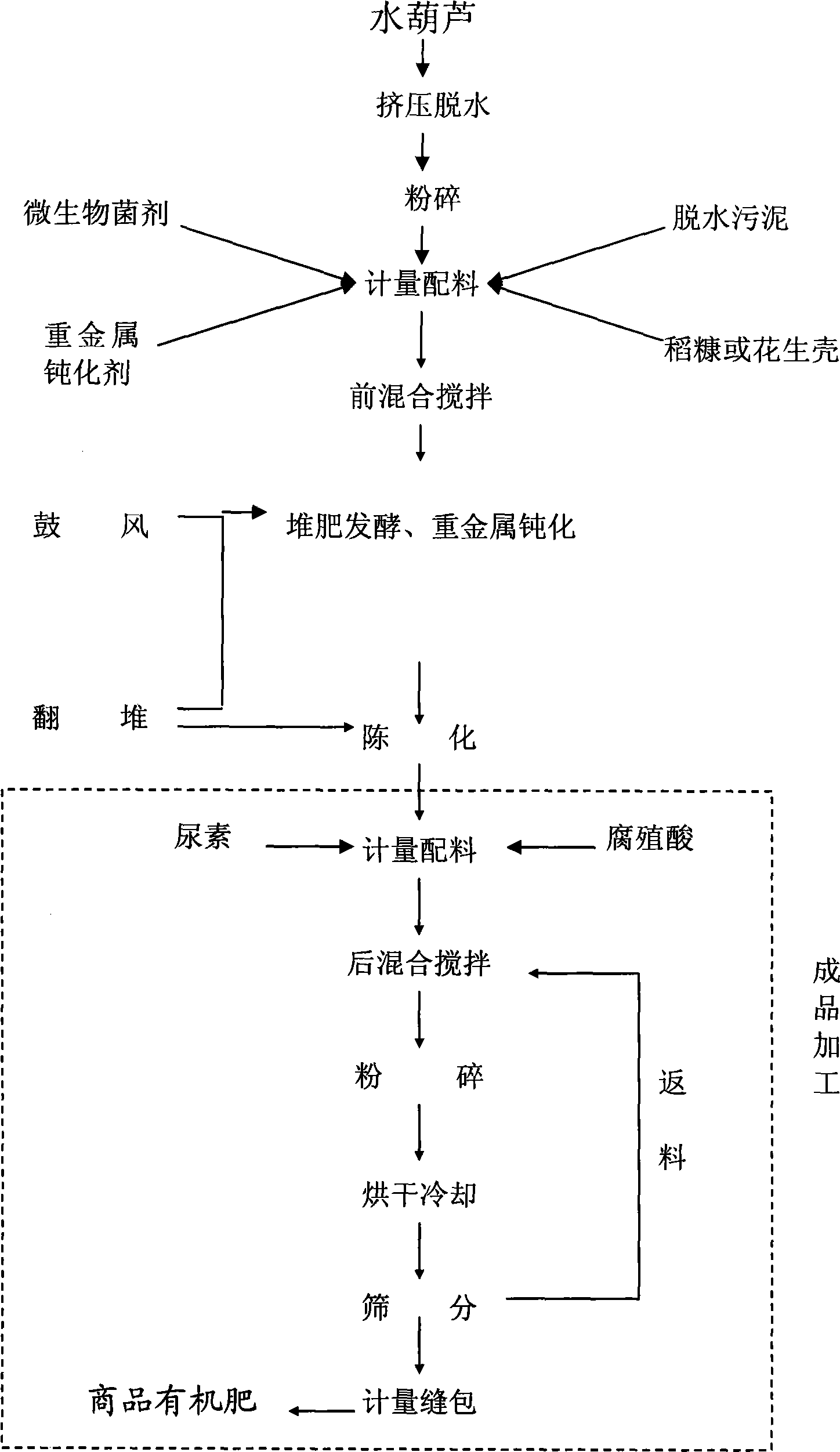

[0031] The main raw materials are water hyacinth, dewatered sludge, microbial agent, rice bran or peanut shell, heavy metal deactivator, etc. Describe the processing process in detail according to the process flow:

[0032] After water hyacinth is squeezed, dehydrated and crushed, it is mixed with dewatered sludge, microbial agent, heavy metal deactivator, rice bran or peanut shell for fermentation and aging (secondary fermentation), and the decomposed clinker after fermentation and aging With a certain amount of humic acid and urea, it will be processed into commercial organic fertilizer.

[0033] (1) Dehydration of water hyacinth

[0034] Extrusion dehydration reduces the moisture content from 95% to about 50%.

[0035] (2) water hyacinth crushed

[0036] Due to the high water content of water hyacinth, a professional grinder must be used to avoid damage to the motor; the fineness is about 3cm, so it does not need to be too precise.

[0037] (3) Measuring ingredients

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com