Ultra-magnetic telescopic driver special for oil membrane bearing

A technology of giant magnetostrictive and giant magnetostrictive rods, which is applied in the direction of piezoelectric effect/electrostrictive or magnetostrictive motors, bearing components, shafts and bearings, which can solve the problem of low adjustment accuracy and slow response speed and other problems to achieve the effect of eliminating frequency doubling, wide static adjustment range and good dynamic response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

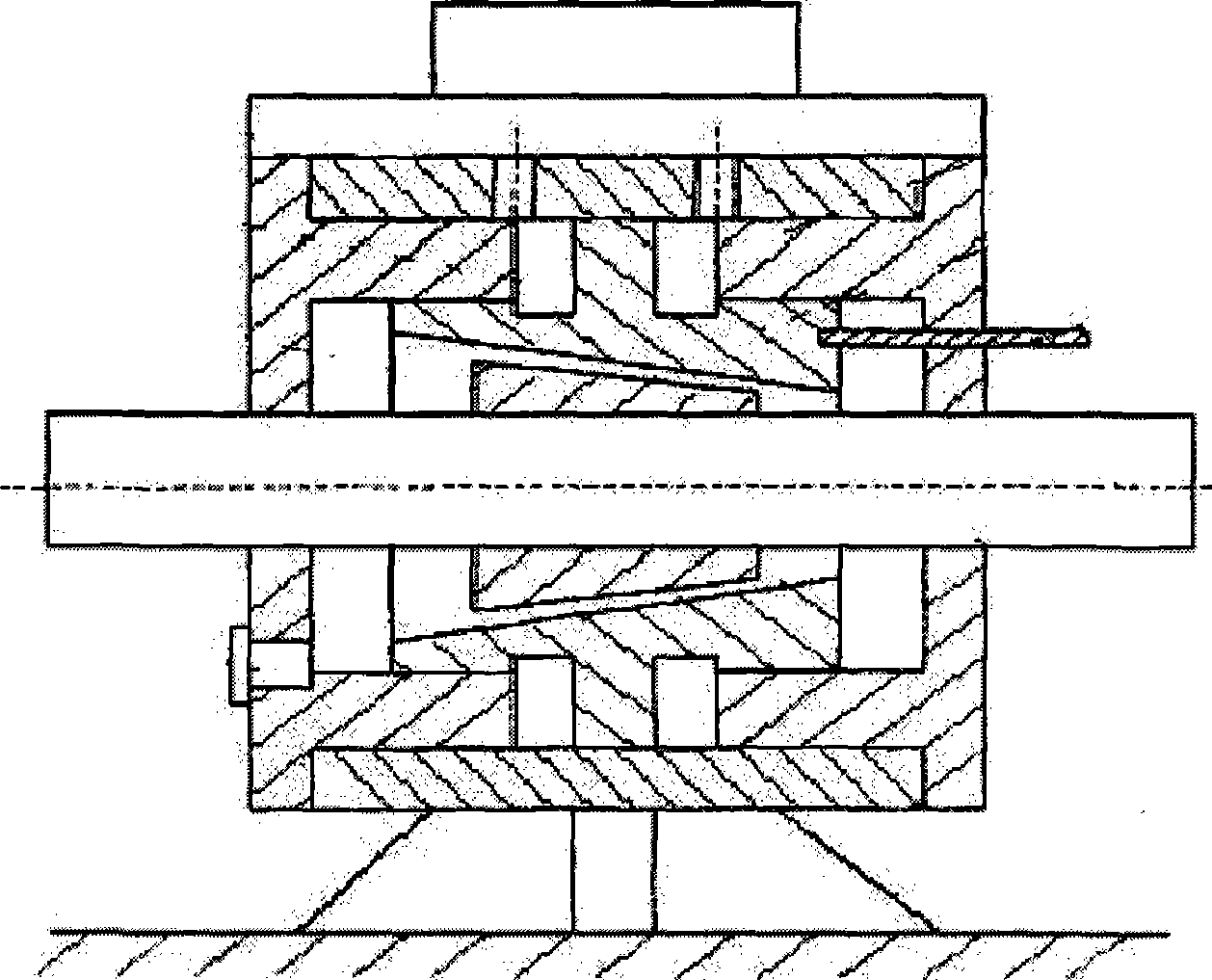

[0022] A preferred embodiment of the present invention is described in detail as follows in conjunction with accompanying drawing:

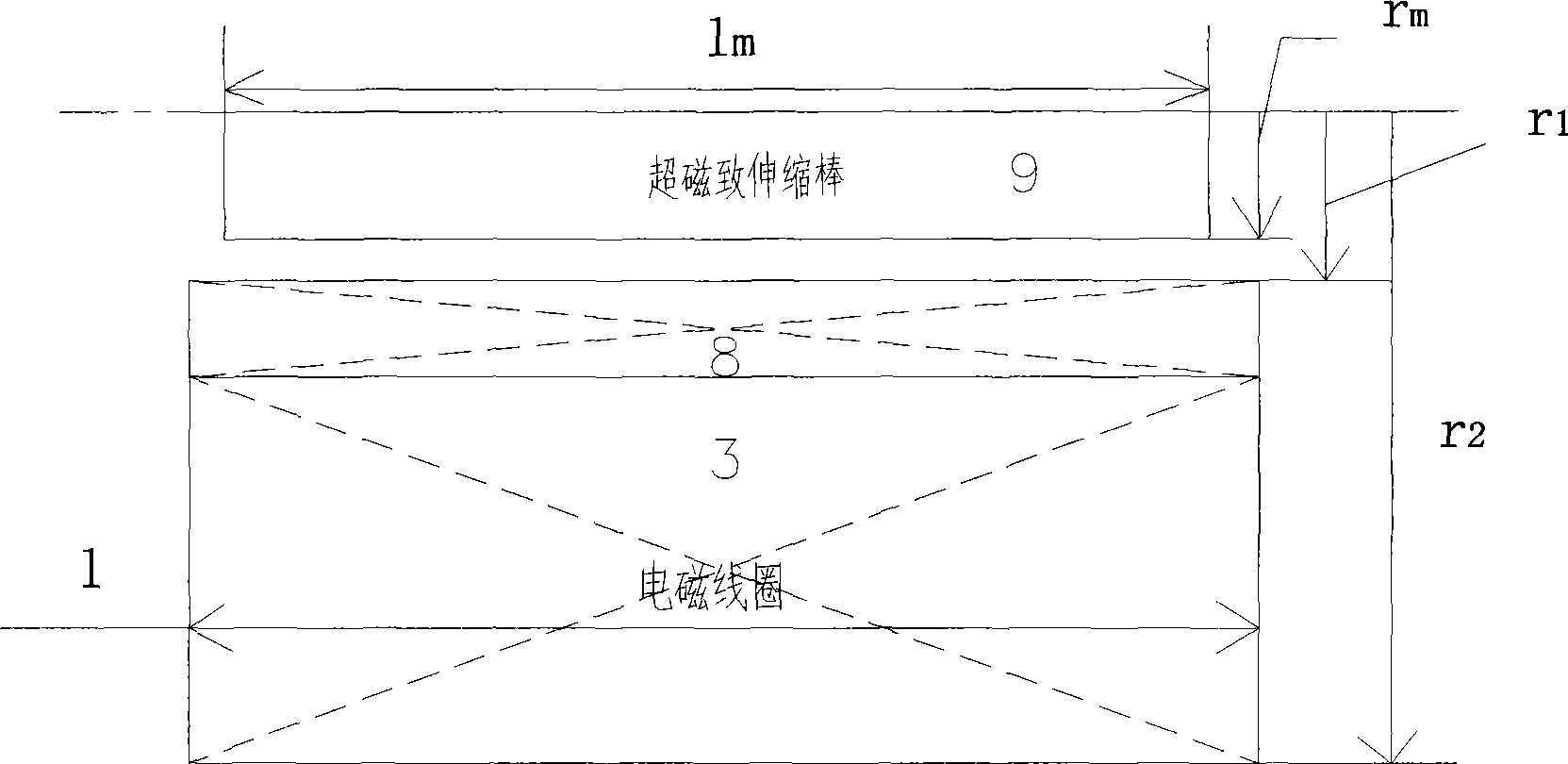

[0023] see figure 2 , The giant magnetostrictive driver dedicated to the oil film bearing includes a base 10 , a casing 2 and an upper cover 6 . It is characterized in that the base 10 is a magnetically conductive base, the outer shell 2 is a magnetically conductive shell, and the upper cover 6 is a non-magnetic upper cover; a giant magnetostrictive rod 9 is placed at the center of the inner cavity of the outer shell 2 , the lower end of which is supported on the base 10, while the upper end is in close contact with a magnetically conductive sealing cover 4; an annular cavity formed between the shell 2, the base 10, the giant magnetostrictive rod 9 and the magnetically conductive sealing cover 4 is placed in an A magnetically conductive coil frame 7, on which a coil is wound; on the magnetically conductive sealing cover 4, a support block 5 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com