Zincium tablet for 9 volt layered dry cell battery and blanking equipment and process

A dry battery and zinc sheet technology, applied to the electrodes of primary batteries, battery electrodes, circuits, etc., can solve problems such as waste of zinc sheets, and achieve the effects of reducing production costs, reducing costs, and stabilizing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

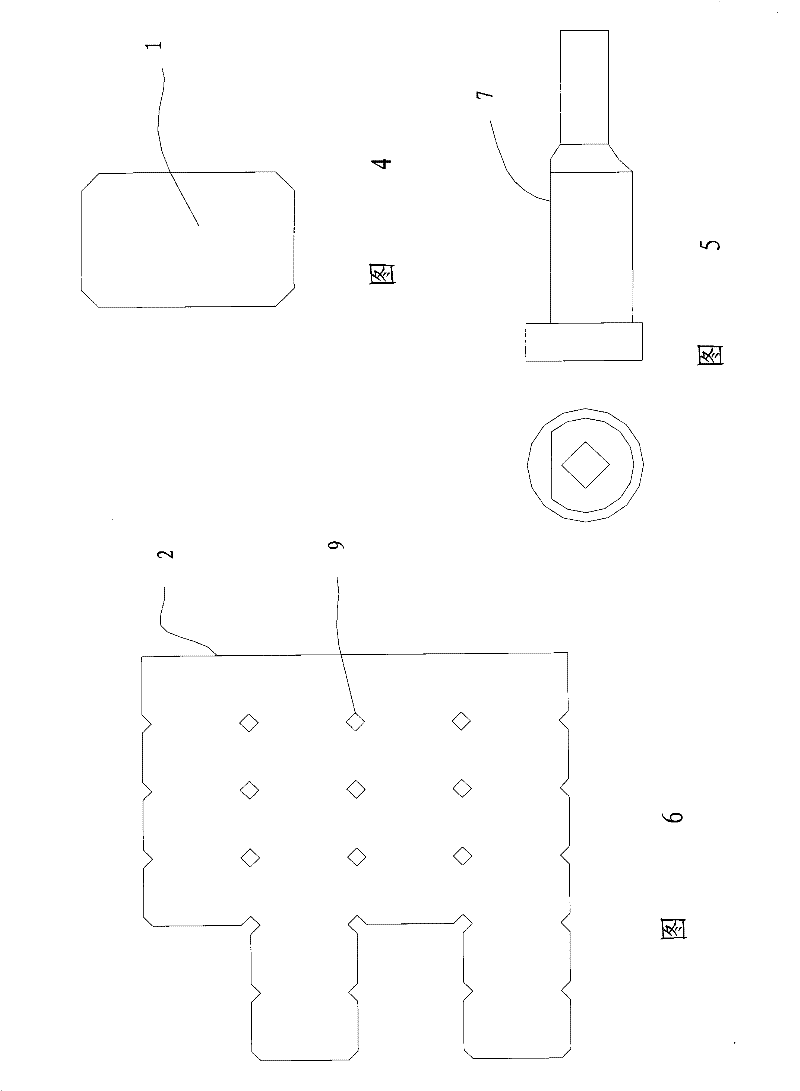

[0025] refer to Figure 4 , a zinc sheet 1 for a nine-volt laminated dry battery, the zinc sheet 1 is a rectangular plate-shaped body whose four vertices are respectively rhombus sides, such as Figure 5 Shown, form the hole 9 of regular rhombus between the adjacent vertices of four adjacent zinc sheets 1, like this, there is no gap between the adjacent zinc sheets on transverse direction and vertical direction, along the hole 9 of regular rhombus Diagonal lines are punched horizontally and vertically respectively, so that the zinc sheet 1 can be obtained directly, and the rhombus-shaped holes 9 are left and right symmetrical, which is more convenient for positioning, reduces the consumption of the zinc sheet, and has less edge waste, which is beneficial to reduce the cost.

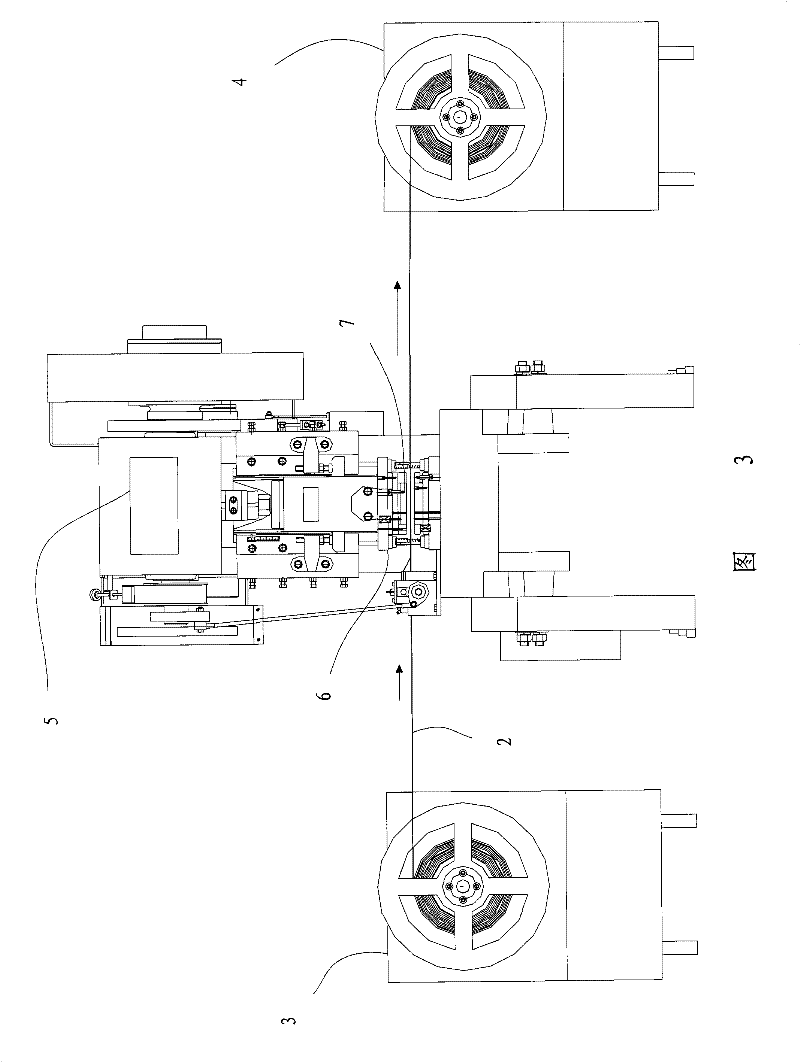

[0026] refer to Figure 6 and Figure 7 , a punching equipment for preparing zinc sheets for nine-volt laminated dry batteries, comprising a zinc sheet seat 3 wound with a continuous zinc sheet 2, a pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com