Method for mounting high pier, tower over-form construction reinforced bar and movable support thereof

A technology of movable brackets and steel bars, which is applied in the fields of formwork/template/work frame, on-site preparation of building components, structural elements, etc., can solve the problems of waste, poor working conditions, low construction efficiency, etc. Management costs, improving operational efficiency, and the effect of a small one-time investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

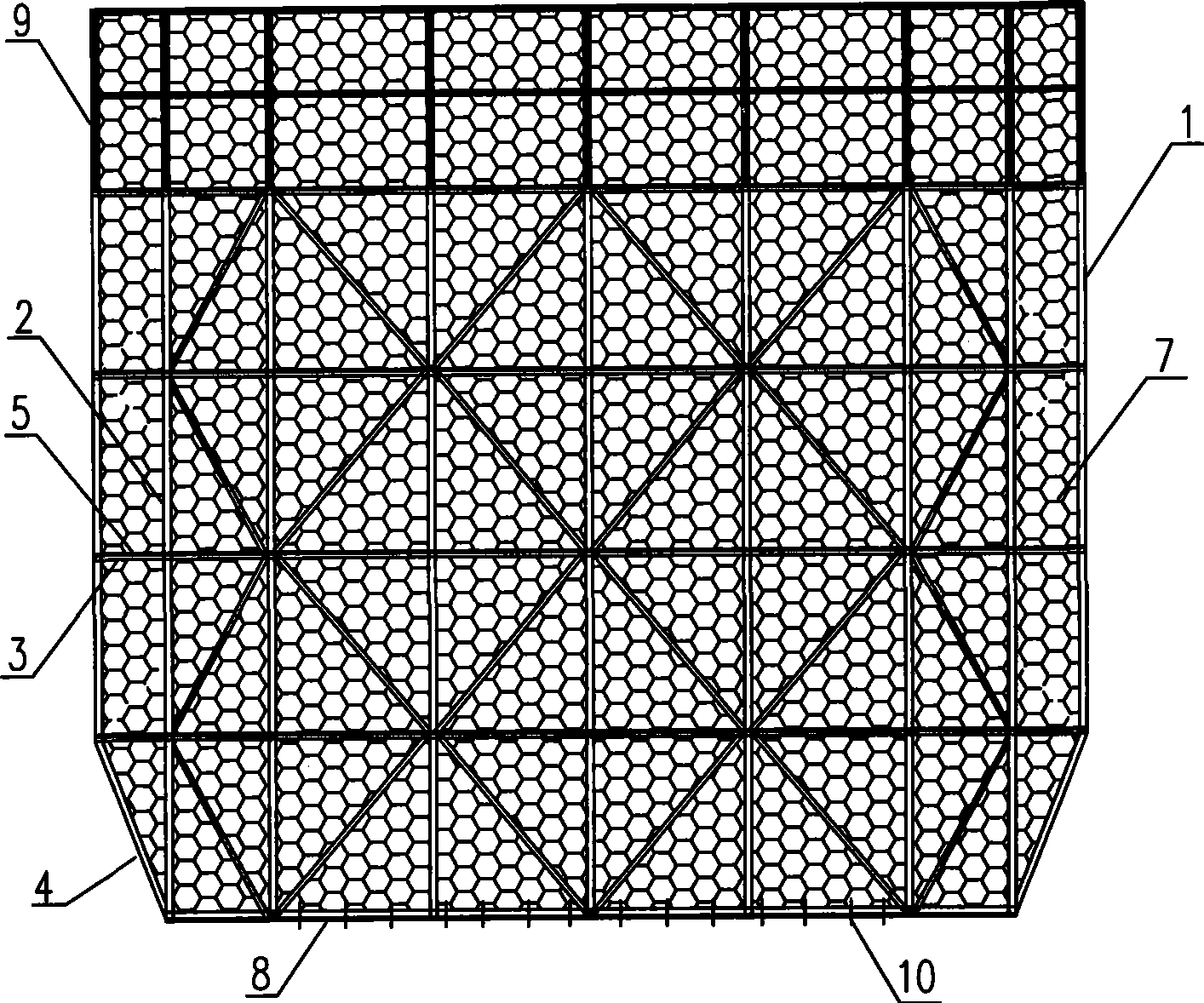

Embodiment 1

[0031] Taking the high pier construction of Qianwei Minjiang Bridge on Leyi Expressway as the background, compared with the traditional construction method, the direct cost saving is more than 600,000 yuan. Sichuan Leyi Expressway Qianwei Minjiang Bridge is located 5 kilometers northwest of Qianwei County, Leshan. The north bank starts from Wayao Bay in Songlin Villa, crosses National Highway 213, Minjiang River, Qianwei-Shixi Highway, and ends at Xiangping Village, Tangba Township. According to the terrain and river conditions, the span combination of Qianwei Minjiang River Bridge is 110m+200m+110m, continuous rigid frame+25×40m simply supported T-beam, and the total length of the bridge is 1438m. The average height of the main pier body, junction pier body and No. 4-18 pier columns of the approach bridge is about 50m. Due to design reasons, no section steel stiff frame is designed in all high piers. With the method for installing steel bars for high pier turning formwork co...

Embodiment 2

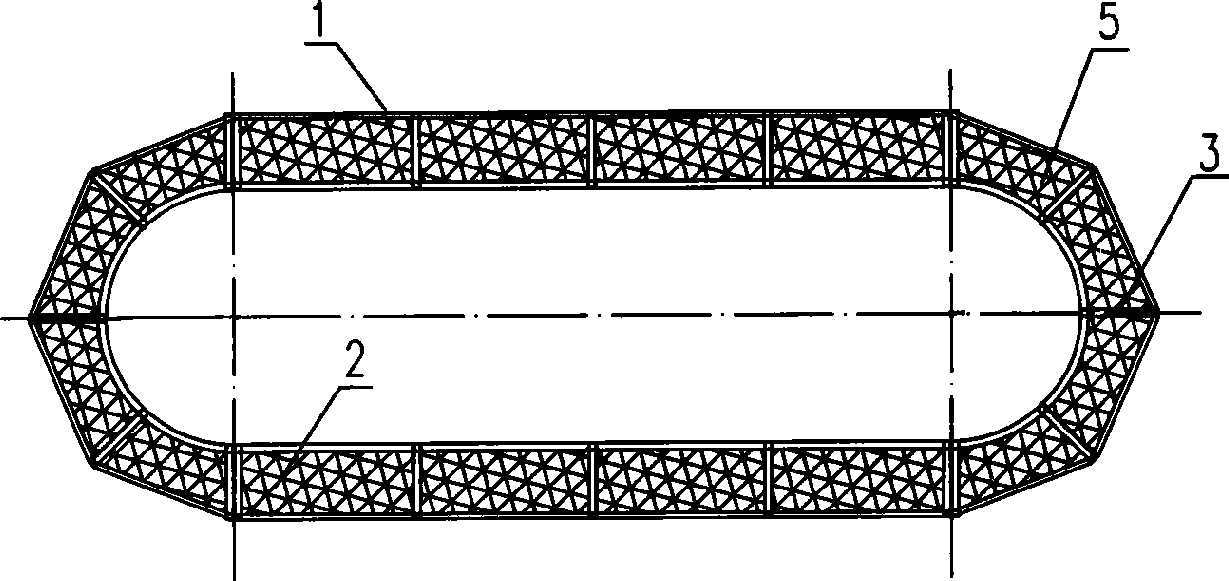

[0048] Such as Figure 4~6 As shown, the method for the installation of high pier turning form construction steel bars of the present invention, except the turning method construction until the construction reaches about 2000mm below the top of the first section steel bar, the height of the first section steel bar is 12m, and the clearance size in the movable support of the approach pier The distance between the outer truss 1 and the inner truss 2 of the movable support of the approach pier is 20mm minus the size of the pier body of the approach pier. Except that it is circular, all the others are the same as in Example 1.

Embodiment 3

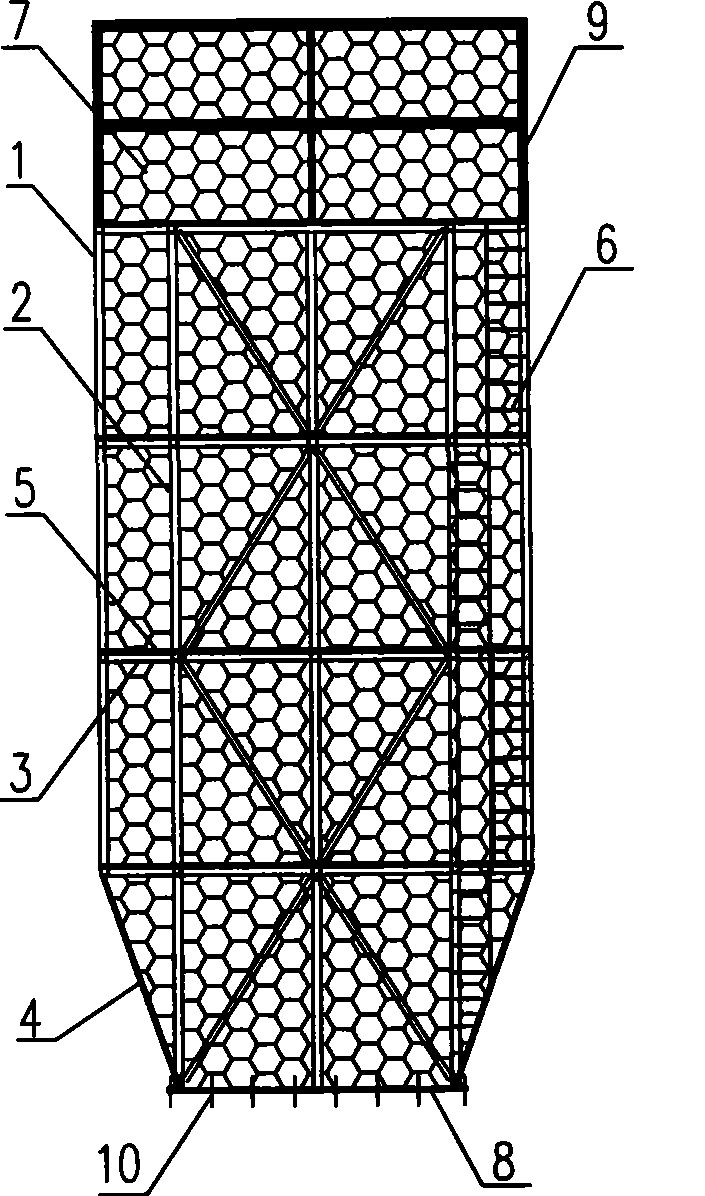

[0050] Such as Figure 7-9 As shown, the method for the installation of high pier turning form construction steel bars of the present invention, except the turning method construction until the construction is about 1250mm below the top of the first section steel bar, the height of the first section steel bar is 10m, and the clearance size in the movable support of the junction pier The pier body size of the junction pier is reduced by 15mm, the distance between the outer truss 1 and the inner truss 2 of the movable support of the junction pier is 800mm, and the shape of the inner space of the cross section of the movable support of the junction pier is the same as the shape of the outer shape of the plane section of the junction pier body. Except for rectangle, all the other are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com