Nano silver calligraphy and painting protecting solution and preparation thereof

A nano-silver, protective liquid technology, applied in the direction of paper, can solve the problems of paper adsorption to glass, difficult to completely isolate the entry of water vapor, difficult to maintain the original appearance of calligraphy and painting, and achieve simple production, high sterilization efficiency and low price. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation one of embodiment 1 nano-silver calligraphy and painting protection solution

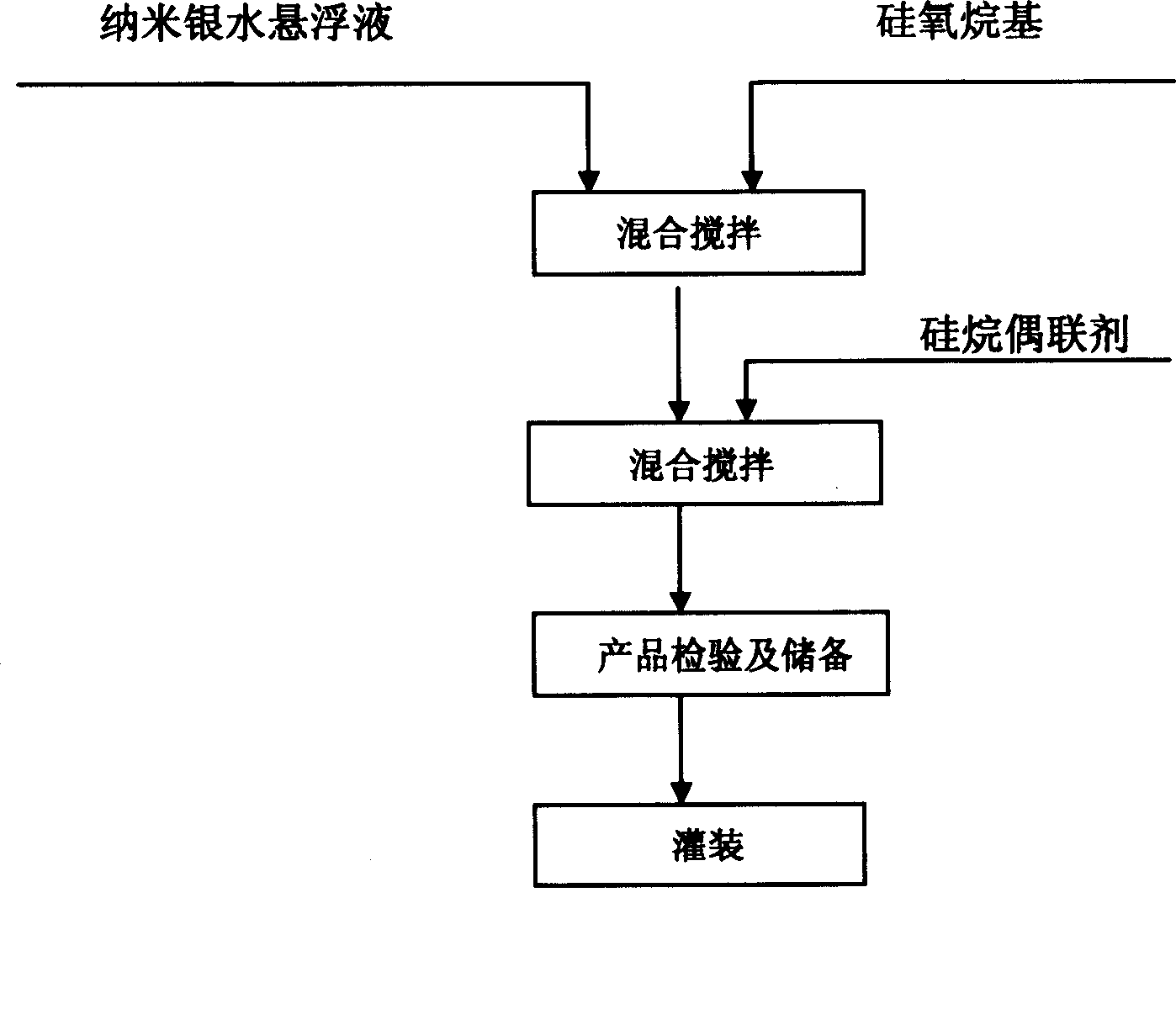

[0035] Referring to the production process diagram, the raw materials are (weight ratio): nano silver aqueous suspension (30ppm), 0.5% siloxane base, 2% silane coupling agent. The production method is as follows: first put 30ppm nano-silver suspension into a stirring container, then add 0.5% siloxane group by weight, stir for 15 minutes, add 2% silane coupling agent, and mix and stir for a certain period of time , poured out to get a new type of liquid.

Embodiment 2

[0036] Embodiment 2 Preparation two of nano-silver calligraphy and painting protection solution

[0037] With reference to the production process diagram, its raw materials are (weight ratio): nano-silver aqueous suspension (70ppm), siloxane 16%, and the present embodiment does not contain silane coupling agent. The preparation method is as follows: first put 70ppm nanometer silver water suspension into a stirring container, then add 16% siloxane group according to the proportion, mix and stir for a certain period of time, and pour out to obtain a new type of liquid.

Embodiment 3

[0038] Example 3 The "nano-silver" antibacterial and waterproof protective liquid prepared by this technology is an alkaline property sterilization experiment.

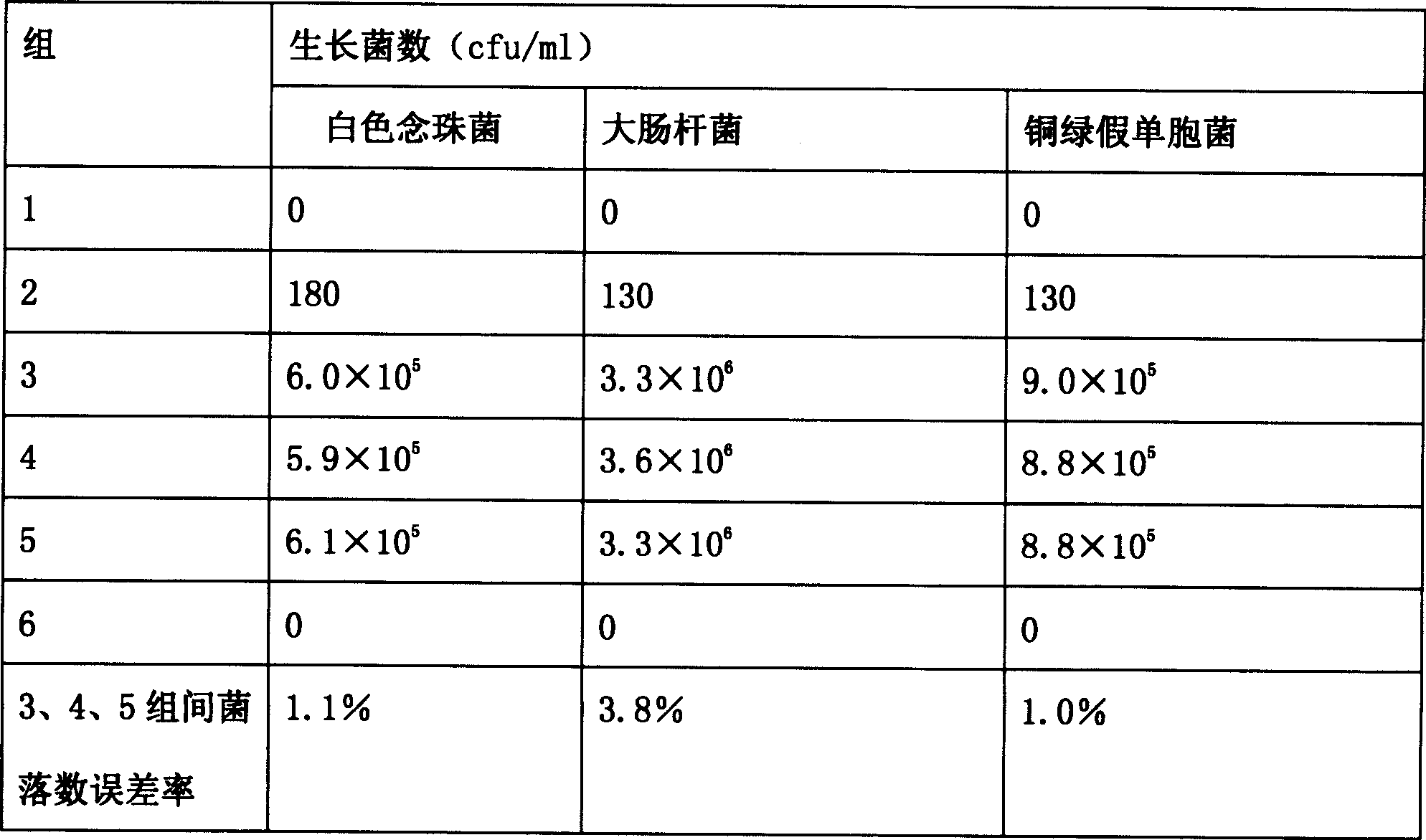

[0039] Quantitative sterilization test results:

[0040]According to GB15981-1995, the quantitative bactericidal test of suspension and carrier was carried out respectively. Each test was repeated five times, and the bacteria in each test were: Candida albicans (ATCC 10231 seventh generation), E. Seventh generation) and Pseudomonas aeruginosa (ATCC 15442 seventh generation), the stock solution was applied to the above strains for 15 minutes respectively. The results are: in the suspension quantitative bactericidal test, the killing rate of the above bacterial strains was greater than 99.9% in the five tests, and in the carrier quantitative bactericidal test, the killing rate of the above bacterial strains was greater than 99.9% in the five tests.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com