Silicon dioxide, preparation and use thereof

A technology of silicon dioxide and emulsifier, applied in the direction of silicon dioxide, silicon oxide, coating, etc., can solve the problem of unsatisfactory performance of matting agent, and achieve smooth hand feeling, good storage performance and high matting efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

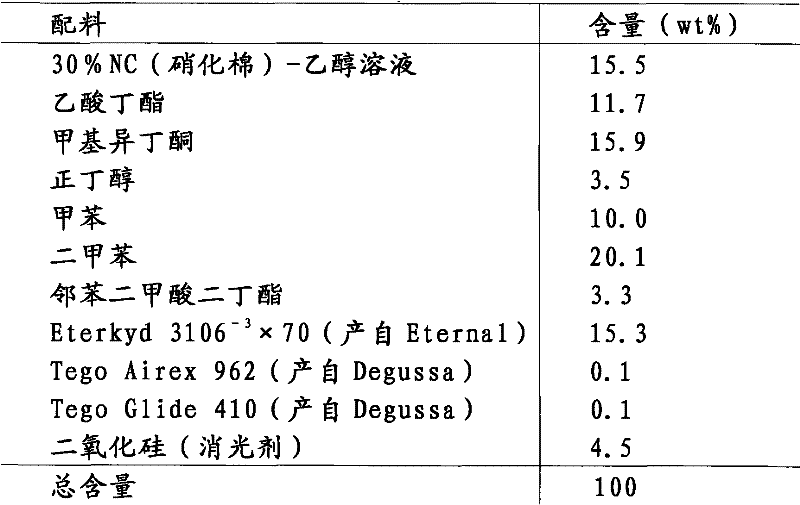

Image

Examples

Embodiment 1

[0049] Inject 200g of wax emulsion with a concentration of 5wt% into 1000ml of sodium silicate solution with a concentration of 1.2M, and then add the sodium silicate solution into a reaction kettle with a stirring device. Add dilute sulfuric acid with a concentration of 30wt% to pH 10, stir for 20 minutes, continue to add acid to pH 3, heat to 60°C, add ammonia water, adjust pH to 10, heat up to 100°C and age for 5 hours, add acid to pH after aging 3. Aging for 1 hour, filtering and washing with deionized water for 3 times, drying and pulverizing to obtain the finished product.

[0050] The preparation method of the wax emulsion is as follows: Take 500g of oxidized polyethylene wax, 25g of fatty alcohol polyoxyethylene ether and 25g of nonylphenol polyoxyethylene ether into a reaction kettle with a heating and stirring device, and heat the resulting mixture to 120°C. After melting, continue to stir for 1 hour. At the same time, add 10L of water to another reaction kettle and ...

Embodiment 2

[0052]Into 1000ml of sodium silicate solution with a concentration of 1.5M, inject 200g of the wax emulsion in Example 1 with a concentration of 5wt%, then add the sodium silicate solution into a reaction kettle with a stirring device, and the temperature is 20°C , add dilute sulfuric acid with a concentration of 20wt% to pH 10 under constant stirring, continue to add acid to pH 4 after stirring for 20 minutes, add ammonia water after heating to 65°C, adjust the pH value to 10, heat up to 100°C and age for 2 hours, after aging Add acid to pH 3, age for 1 hour, filter and wash 3 times with deionized water, dry and pulverize to obtain the finished product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com