Negative pole material for lithium ionic cell and preparation process thereof

A technology for lithium-ion batteries and negative electrode materials, applied in electrode manufacturing, battery electrodes, circuits, etc., can solve the problem of low charge and discharge performance of negative electrode materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 5 grams of flake graphite with a particle size of 30 microns, 4 grams of sodium nitrate and 25 grams of potassium permanganate were added to 600 grams of concentrated sulfuric acid with a mass fraction of 98%, stirred for 120 hours, filtered and washed, and placed in an aqueous solution to Ultrasonic at 200W power for 6 hours, add 10 grams of stannous chloride dihydrate and 1 gram of hydrazine hydrate, continue to stir for 24 hours, filter, wash, and dry to obtain a lithium ion battery negative electrode material.

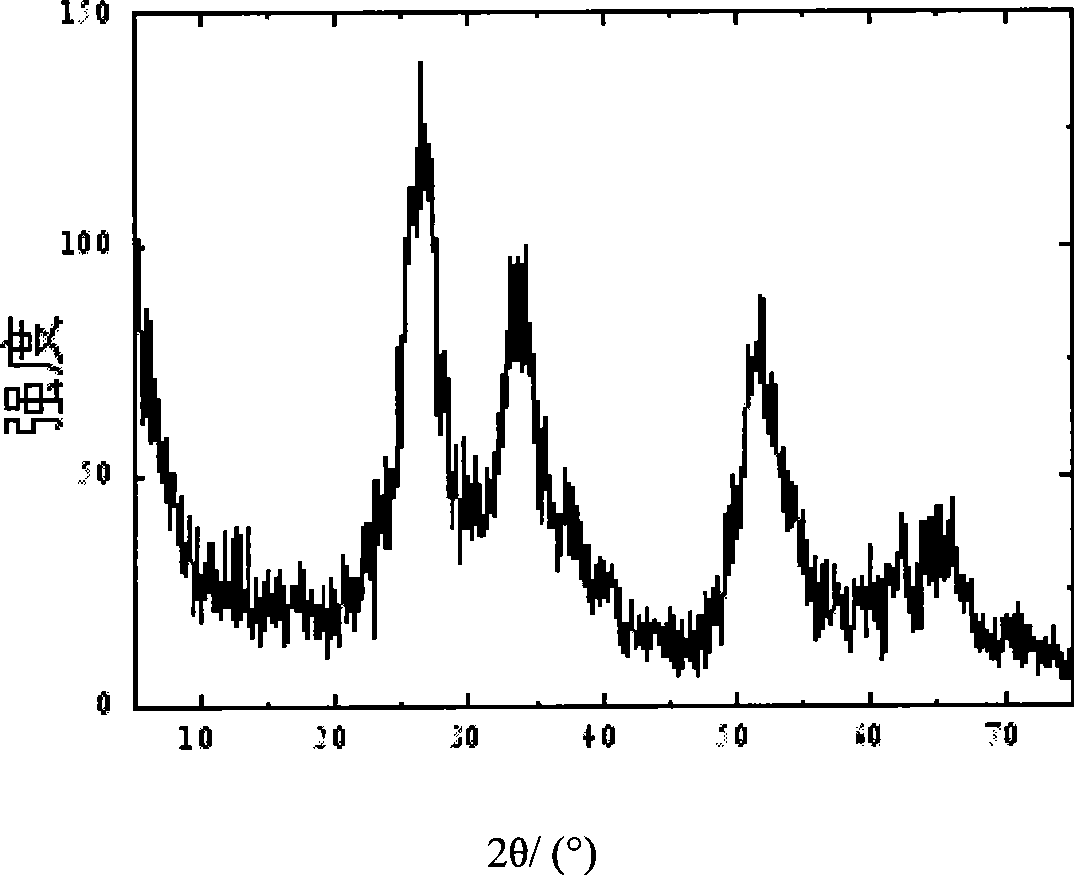

[0026] figure 1 It is the X-ray diffraction pattern of the lithium-ion battery negative electrode material that example 1 obtains, that is, graphene nanosheets supported tin dioxide. Depend on figure 1 It can be seen from the diffraction peaks that the negative electrode material mainly contains tin dioxide.

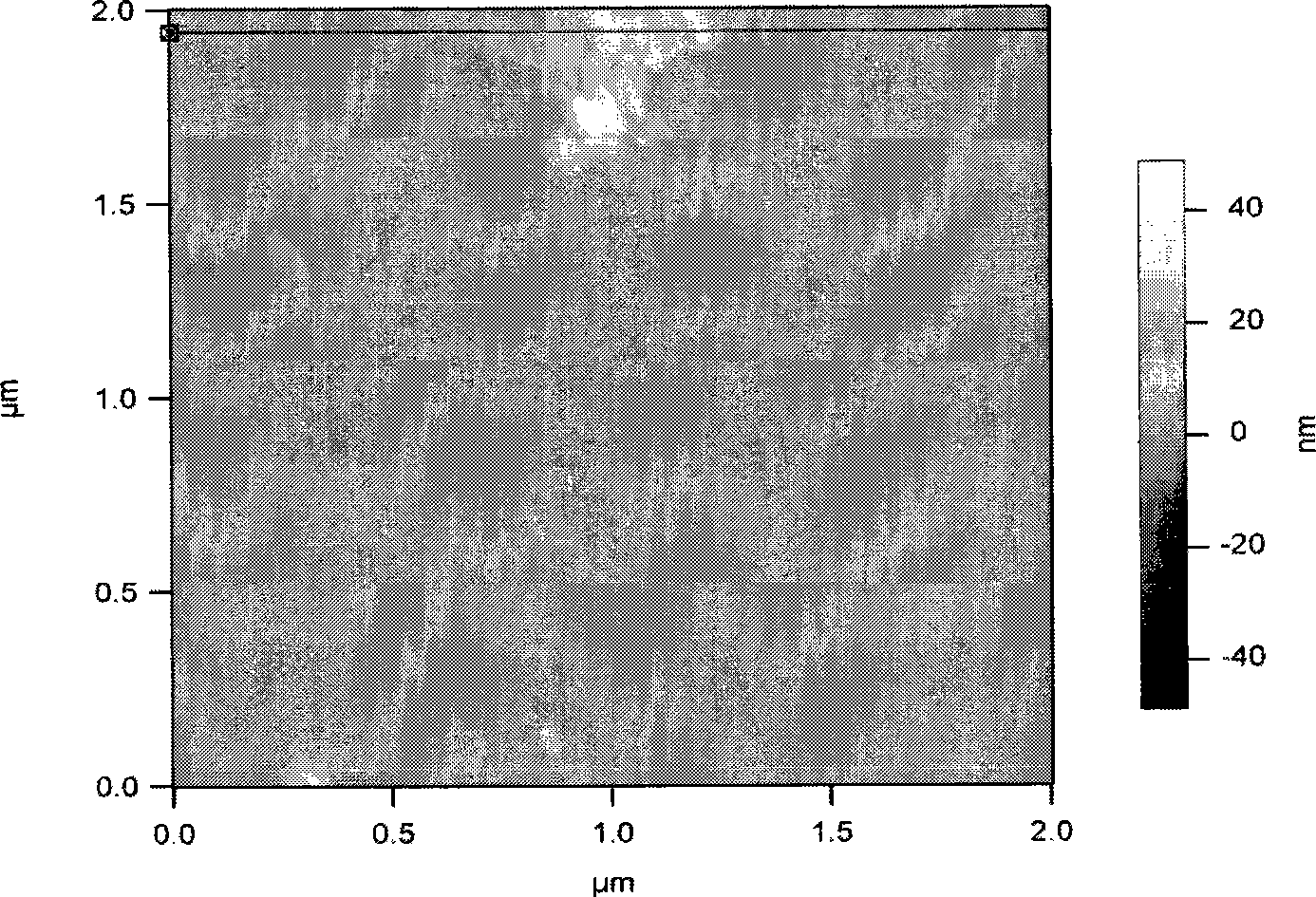

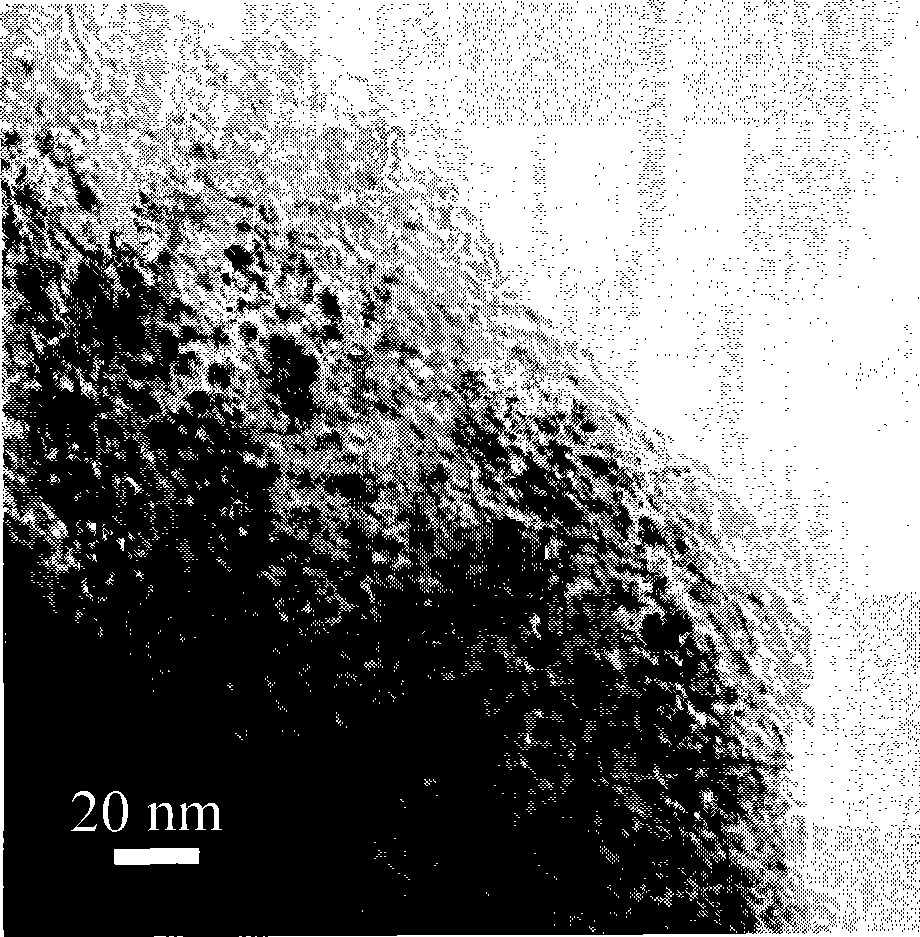

[0027] figure 2 It is the atomic force micrograph of the lithium ion battery negative electrode material prepared by example 1. Depend on figur...

Embodiment 2

[0032] 5 grams of flake graphite with a particle size of 30 microns, 4 grams of sodium nitrate and 25 grams of potassium permanganate were added to 600 grams of concentrated sulfuric acid with a mass fraction of 98%, stirred for 120 hours, filtered and washed, and then placed in an aqueous solution. Ultrasonic at 200W for 6 hours, add 5 grams of stannous nitrate dihydrate and 1 gram of sodium borohydride, continue to stir for 24 hours, filter, wash, and dry to obtain a lithium-ion battery negative electrode material. The thickness of the graphene nanosheets in the obtained graphene nanosheets loaded tin dioxide is 1-30 nanometers, and the particle diameter of tin dioxide is 1-4 nanometers. -1 The reversible specific capacity of the current charge and discharge test is 520mAh·g -1 .

Embodiment 3

[0034] 5 grams of flake graphite with a particle size of 30 microns, 4 grams of sodium nitrate and 25 grams of potassium permanganate were added to 600 grams of concentrated sulfuric acid with a mass fraction of 98%, stirred for 120 hours, filtered and washed, and then placed in an aqueous solution. Ultrasonic at 200W power for 6 hours, add 1 gram of stannous sulfate and 1 gram of ascorbic acid, continue to stir for 24 hours, filter, wash and dry to obtain a lithium ion battery negative electrode material. The thickness of the graphene nanosheets in the obtained graphene nanosheets loaded tin dioxide is 1-30 nanometers, and the particle diameter of tin dioxide is 1-3 nanometers. -1 The reversible specific capacity of the current charge and discharge test is 480mAh·g -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com