Boiler with continuous water supply

A technology for water heaters and heating furnaces, applied in the field of boilers, which can solve problems such as low hot water temperature, low thermal efficiency, and direct discharge of hot exhaust gas, and achieve the effects of rapid water temperature rise, long heating path, and increased temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

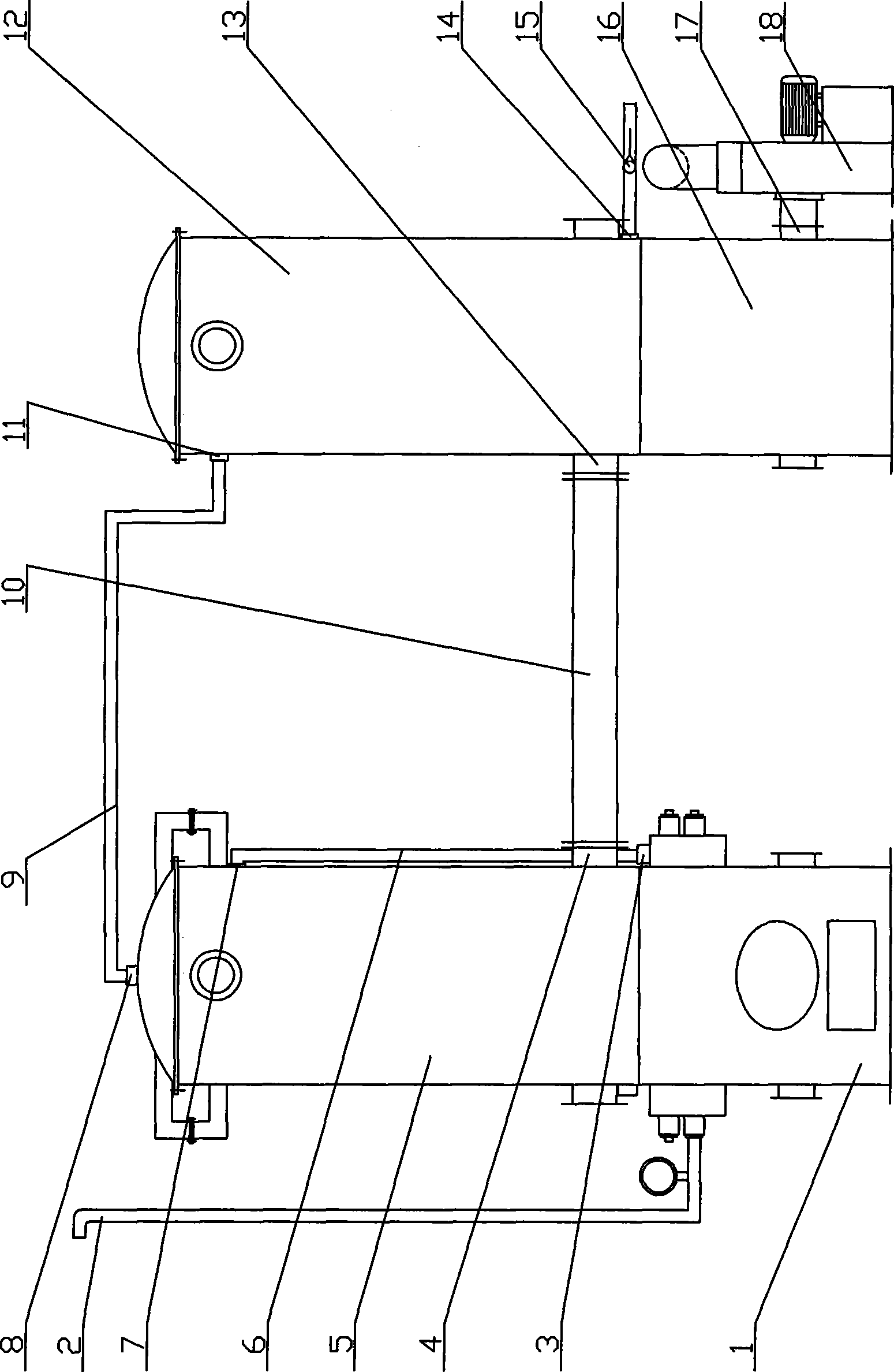

Embodiment 1

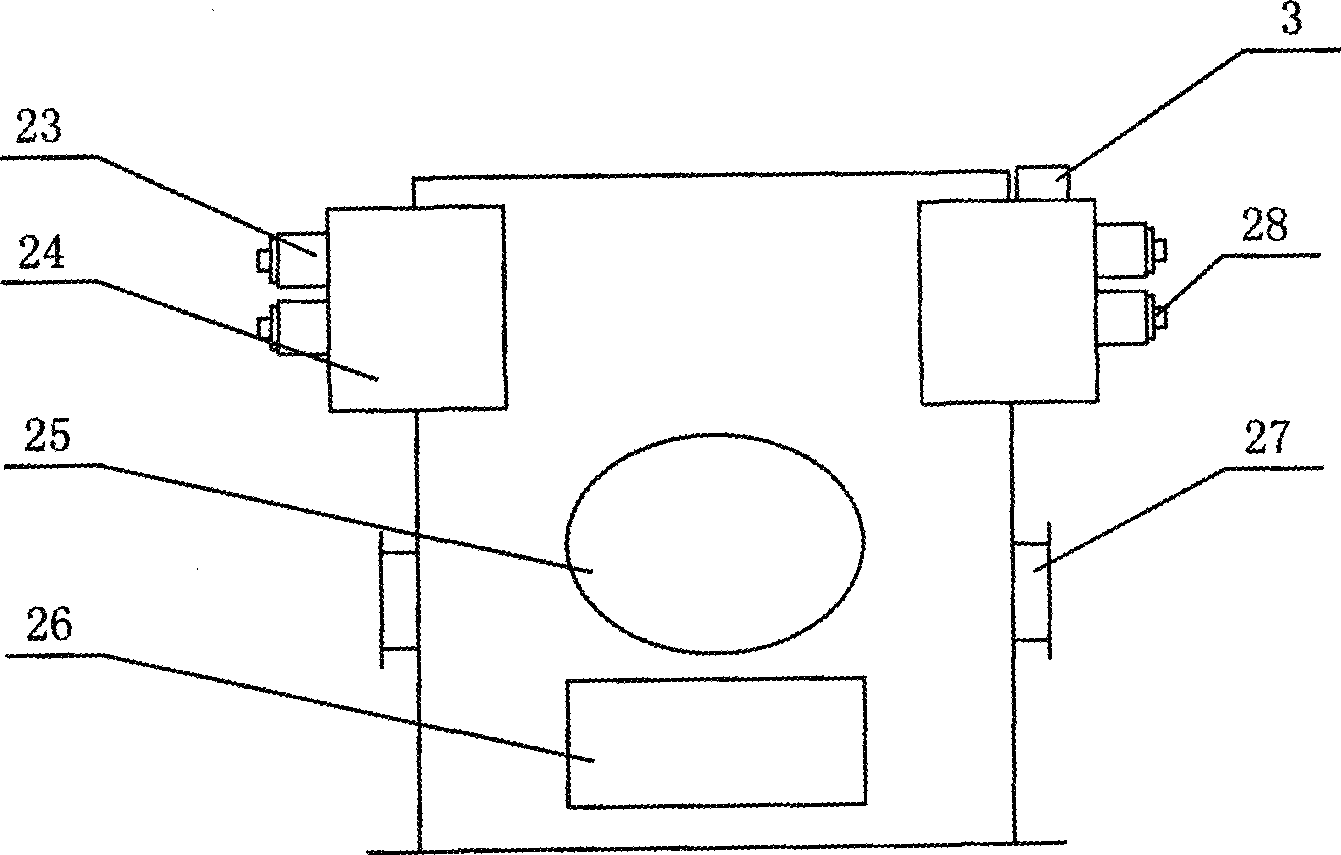

[0036] A continuous water supply hot water heater, which includes a heating furnace 1, a main water tank 5, an auxiliary water tank 12, an auxiliary water tank base 16 and an exhaust fan 18.

[0037] The heating furnace is mainly composed of a furnace body 32 and a waste heat utilization device, and the waste heat utilization device includes a water jacket 24 and a heating water pipe 23 . The water jacket 24 is in the shape of a tube with ears on both sides, and is arranged around the furnace body 32 . There are seven heating water pipes 23 arranged in two layers, three on the upper floor and four on the lower floor. The upper and lower layers of heating water pipes 23 are arranged in a staggered manner. All the heating water pipes 23 are connected in series, and the way of series connection can be the adjacent series connection of jumping floors, or can be series connection with another floor after being connected in series with the same floor. The two ends of every heating ...

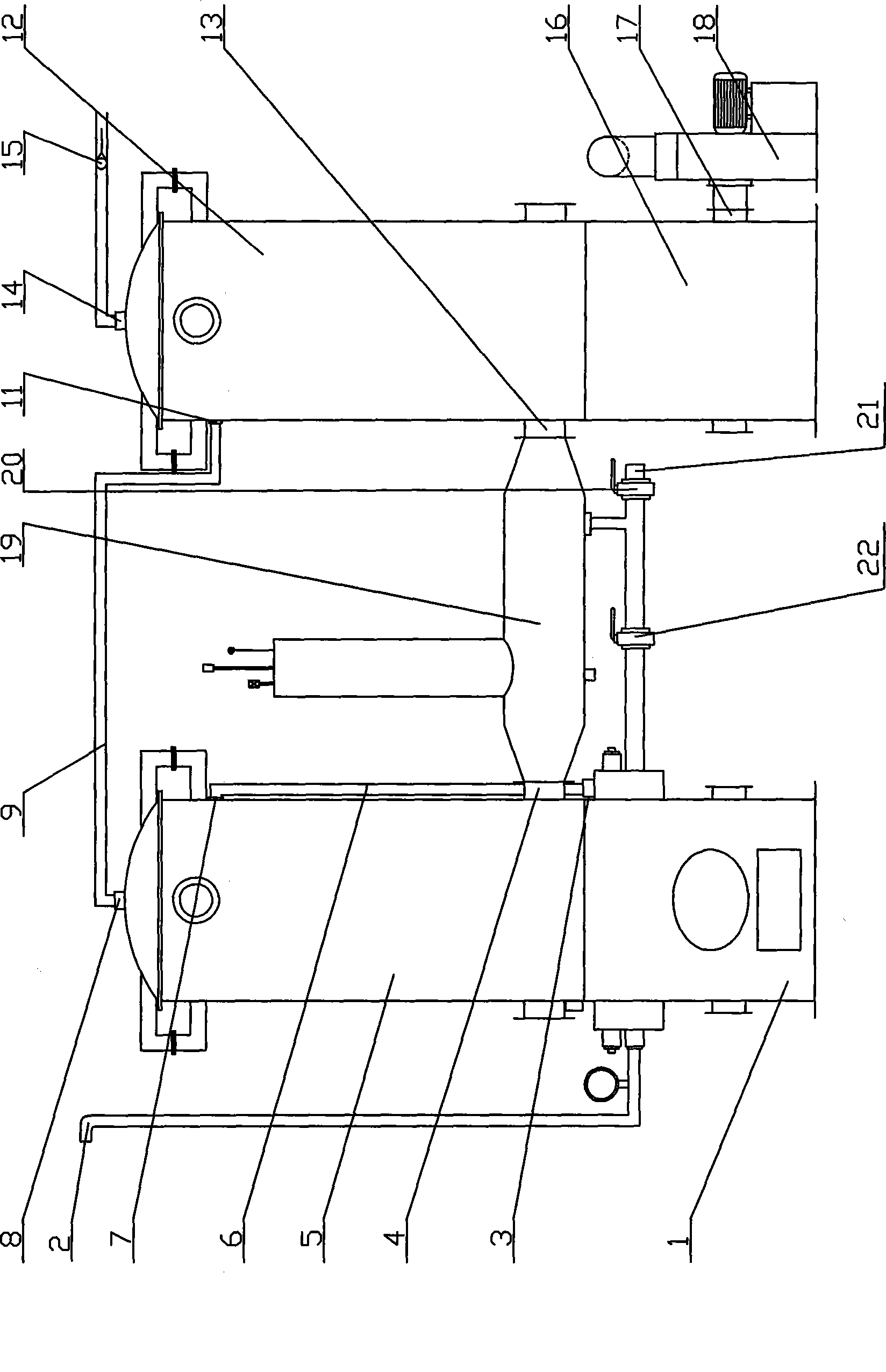

Embodiment 2

[0043] A continuous water supply water heater, which includes a heating furnace 1, a main water tank 5, a waste heat boiler 19, an auxiliary water tank 12, an auxiliary water tank base 16 and an exhaust fan 18.

[0044] The heating furnace is mainly composed of a furnace body 32 and a waste heat utilization device, and the waste heat utilization device includes a water jacket 24 and a heating water pipe 23 . The water jacket 24 is in the shape of a tube with ears on both sides, and is arranged around the furnace body 32 . There are seven heating water pipes 23 arranged in two layers, three on the upper floor and four on the lower floor. The upper and lower layers of heating water pipes 23 are arranged in a staggered manner. All the heating water pipes 23 are connected in series, and the way of series connection can be the adjacent series connection of jumping floors, or can be series connection with another floor after being connected in series with the same floor. The two en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com