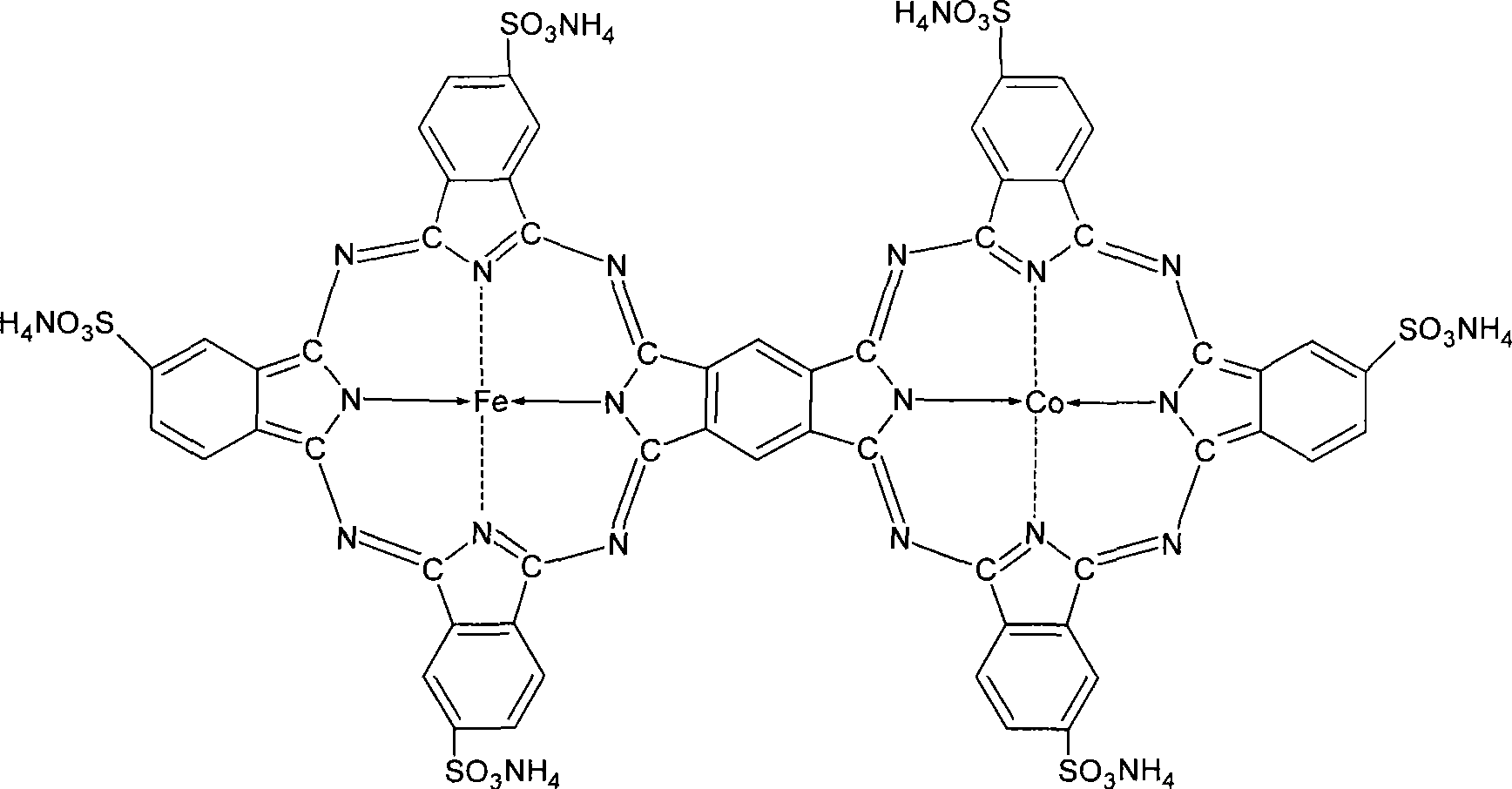

Phthalocyanine iron cobalt sulphonate desulphurization catalyst and preparation method thereof

A technology of ammonium iron cobalt phthalocyanine sulfonate and desulfurization catalyst, which is applied in the field of fine chemical material preparation, can solve the problems of low desulfurization efficiency and low solubility, and achieve high desulfurization efficiency, high recovery rate, and high gas purification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Get phthalic anhydride 1000g, vanadium pentoxide 1.3g, 25% oleum 2980g, put into the reactor and stir constantly, and when heating up to 30 DEG C, after stopping heating, the exothermic reaction begins to heat up naturally, After keeping the reaction for 3 hours, start heating to 235°C, keep the reaction at 235°C for 2-7 hours, then conduct sampling inspection, if it can be dissolved in water immediately, the reaction is over, add calcium oxide to neutralize the unreacted sulfuric acid, Cool down to 50°C and discharge, filter and neutralize with ammonia water to a pH value of about 6-7, and then concentrate to obtain a solid sulfonate. Weigh 1015g of sulfonate, 950g of urea, 54g of cobalt chloride, 23g of ferric chloride, and 3.7g of ammonium molybdate. Slowly raise the temperature, and keep stirring during the reaction to ensure uniform heating and mass transfer. When heated to 140-150°C When the temperature is further increased to 260°C, the reaction is maintained for...

Embodiment 2

[0025] Get phthalic anhydride 1000g, vanadium pentoxide 1.3g, 25% oleum 2980g, put into the reactor and stir constantly, and when heating up to 30 DEG C, after stopping heating, the exothermic reaction begins to heat up naturally, After keeping the reaction for 3 hours, start heating to 235°C, keep the reaction at 235°C for 2-7 hours, then conduct sampling inspection, if it can be dissolved in water immediately, the reaction is over, add calcium oxide to neutralize the unreacted sulfuric acid, Cool down to 50°C and discharge, filter and neutralize with ammonia water to a pH value of about 6-7, and then concentrate to obtain a solid sulfonate. Weigh 510g of sulfonate, 475g of urea, 27g of cobalt chloride, 12g of ferric chloride, and 1.8g of ammonium molybdate. Slowly raise the temperature, and keep stirring during the reaction to ensure uniform heat and mass transfer. When heated to 140-150°C When the temperature is further increased to 260°C, the reaction is maintained for 3 h...

Embodiment 4

[0027] Get phthalic anhydride 500g, vanadium pentoxide 0.5g, 25% oleum 1500g, put into reactor and constantly stir evenly, and when heating up to 30 ℃, after stopping heating, reaction exotherm begins to heat up naturally, After keeping the reaction for 3 hours, start heating to 235°C, keep the reaction at 235°C for 2-7 hours, then conduct sampling inspection, if it can be dissolved in water immediately, the reaction is over, add calcium oxide to neutralize the unreacted sulfuric acid, Cool down to 50°C and discharge, filter and neutralize with ammonia water to a pH value of about 6-7, and then concentrate to obtain a solid sulfonate. Weigh 765g of sulfonate, 710g of urea, 41g of cobalt chloride, 18g of ferric chloride, and 2.8g of ammonium molybdate. Slowly raise the temperature. Stir continuously during the reaction to ensure uniform heat and mass transfer. When heated to 140-150°C When the temperature is further increased to 260°C, the reaction is kept for 3 hours to form a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com