Device for removing sulfuric dioxide in exhaust gas

A sulfur dioxide and exhaust gas technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of increased resistance to gas rise, uneven gas distribution, and increased height of the desulfurization tower to achieve increased absorption rate and full Utilize equipment space and promote the effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

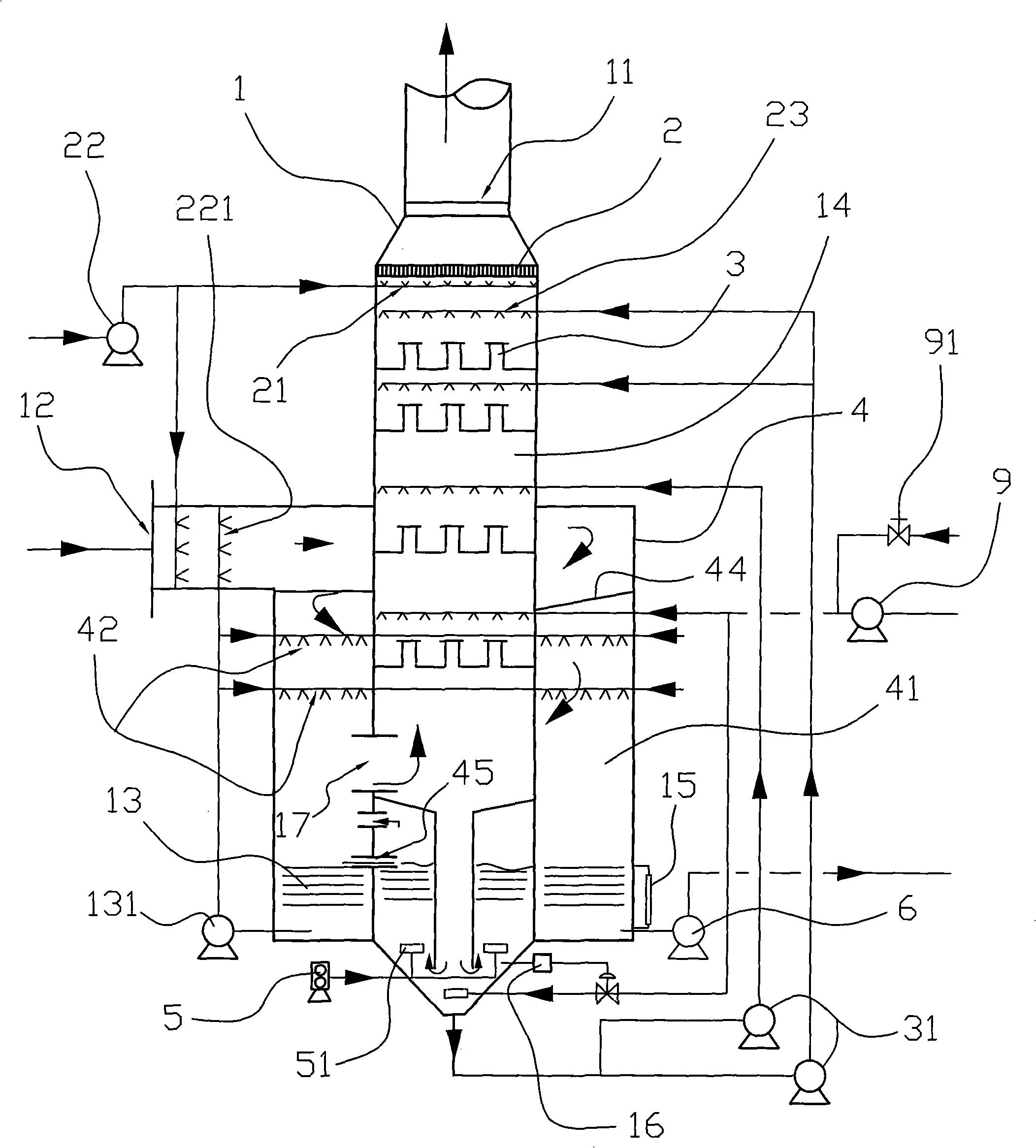

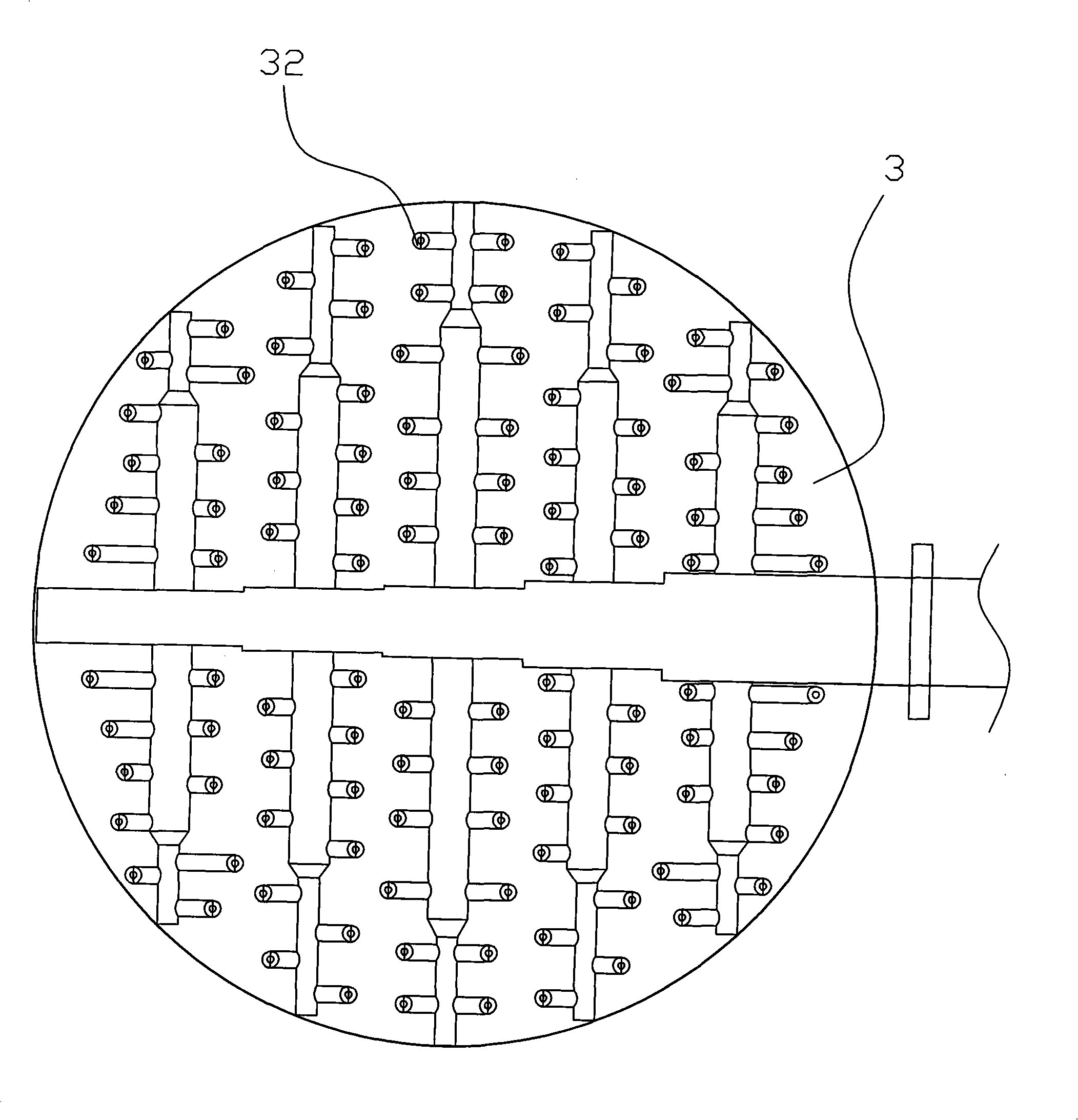

[0022] Embodiment one, such as figure 1 , Figure 3 to Figure 5As shown, the device for removing sulfur dioxide in the waste gas in this embodiment includes an absorption tower 1, a waste gas inlet 12 is arranged on the side of the middle part of the absorption tower 1, and a gas-liquid distributor 3 is arranged in the absorption tower 1, The top of the absorption tower 1 is provided with a clean gas discharge port 11, and the bottom of the absorption tower 1 is provided with an absorption liquid concentrated oxidation zone 13, and the concentrated oxidation zone 13 communicates with the air pipe provided with the air blower 5 in the outside through a pipeline, so that Oxidation in air can oxidize ammonium sulfite or ammonium bisulfite. The gas-liquid distributor 3 communicates with the absorption liquid in the concentrated oxidation zone 13 through a pipeline through a circulation pump 31 . The exhaust gas inlet 12 is connected with the cooling device in the absorption towe...

Embodiment 2

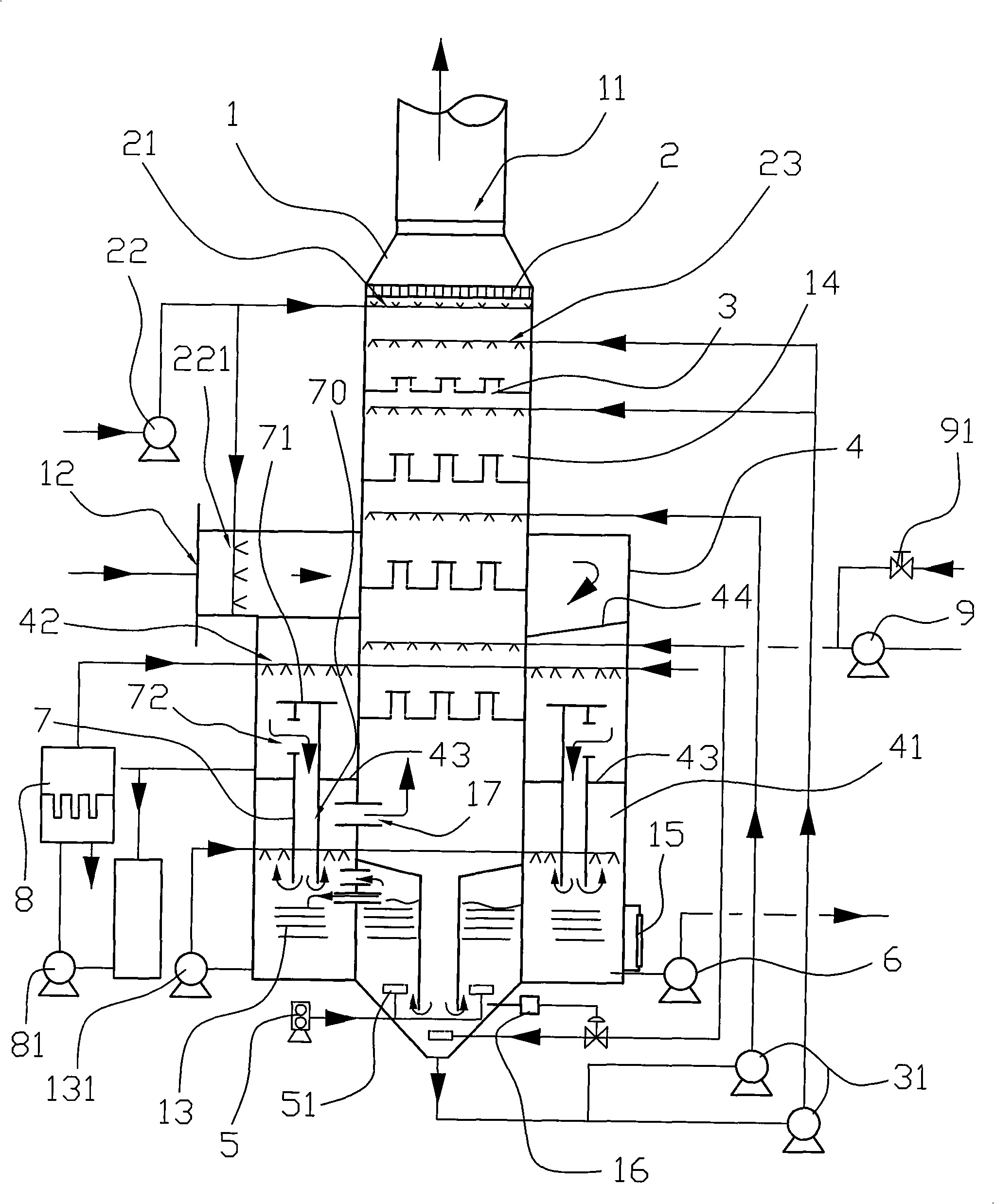

[0023] Embodiment two, such as figure 2 As shown, the basic structure of this embodiment is the same as that of Embodiment 1, the difference is that a dust removal mechanism is provided in the annular chamber 41, and the structure of the dust removal mechanism is: a vertically arranged annular Frame 7, the top of ring frame 7 is provided with the liquid baffle plate 71 that prevents liquid from entering ring frame cavity 70, has the inlet hole 72 that can make waste gas enter ring frame cavity 70 on the side that is positioned at ring frame 7, and ring The inner cavity 70 of the frame is connected with the concentrated oxidation zone 13, and a splint 43 is arranged in the annular cavity 41 to prevent the absorption liquid from entering the concentrated oxidation zone 13. The device 8 is connected, and the outlet of the absorption liquid filter 8 is connected with the sprayer 42 through a pipeline.

[0024] The present invention will be further described below.

[0025] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com