Tissue regeneration membrane with bioactivity and preparation method thereof

A tissue regeneration membrane and biological activity technology, applied in the direction of prosthesis, surgery, medical science, etc., can solve the problems of easy acid production, inflammatory reaction in the implanted area, rejection reaction, etc., achieving easy control, simple preparation method, suitable for wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1: Bioactive Tissue Regeneration Membrane for Periodontal Tissue Regeneration

[0022] (1) Select clean and decontaminated silk in 0.5% Na 2 CO 3 In aqueous solution, degumming twice at 100°C, 1 hour each time, bath ratio 1:50. The degummed silk fibroin was dried in a drying oven at 80°C until dry. Take 10 grams of degummed silk fiber and dissolve it in 100ml of calcium chloride / ethanol / water ternary solution (the molar ratio of calcium chloride, ethanol, and water is 1:2:8), and dissolve it with magnetic stirring at a constant temperature of 70°C . The silk fibroin solution obtained above is dialyzed, desalted and purified to obtain a water-soluble silk fibroin solution with a concentration of 2.5-3.5%, which is concentrated and dried to obtain silk fibroin.

[0023] (2) Weigh 6g of silk fibroin with a balance, add it to 20ml of deionized water, swell at room temperature, stir and dissolve for 1-3 hours until the silk fibroin is completely dissolved, defoam...

Embodiment 2

[0024] Example 2: Bioactive Tissue Regeneration Membrane for Bone Tissue Regeneration

[0025] (1) Silk fibroin is obtained in the same manner as in Example 1.

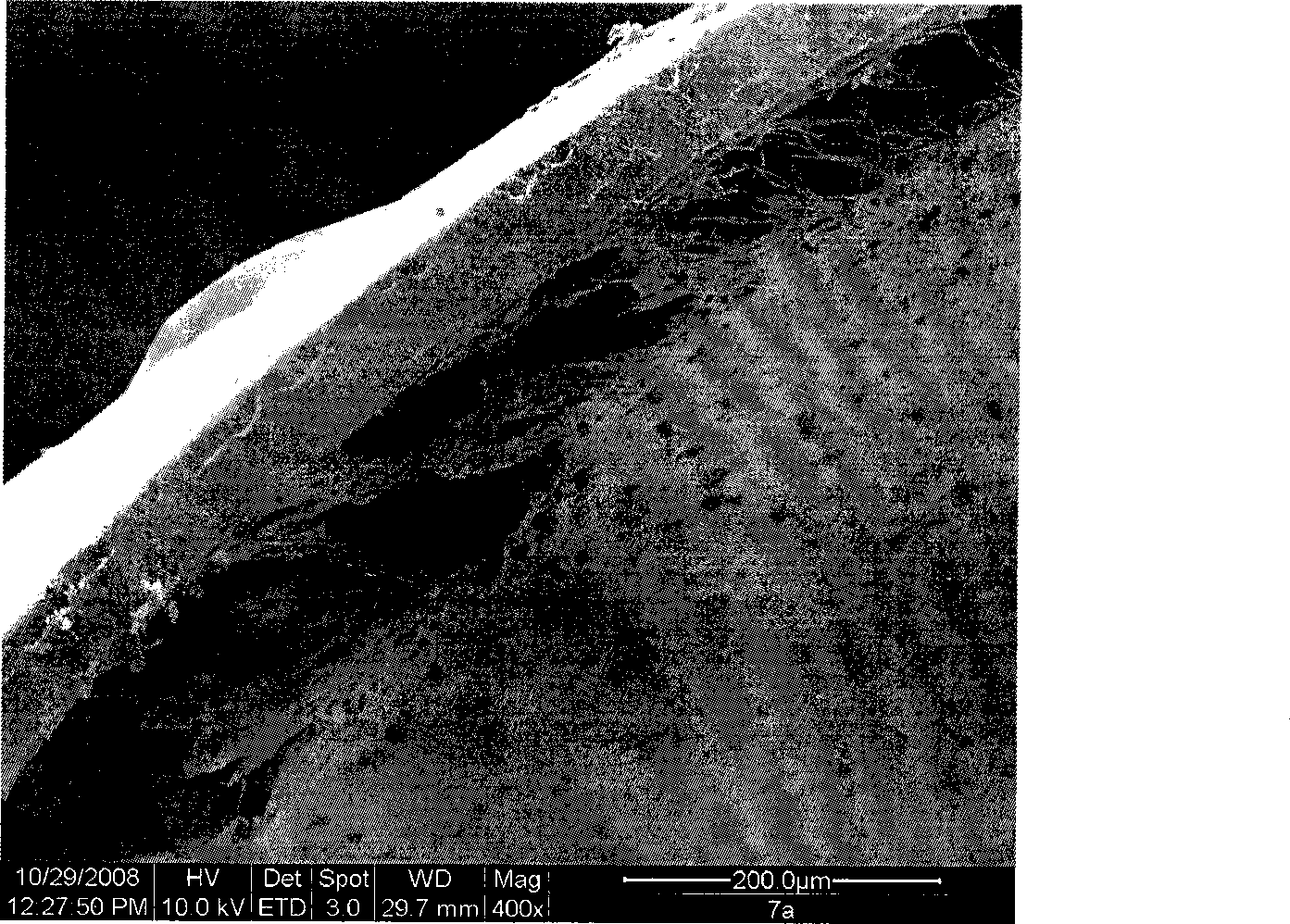

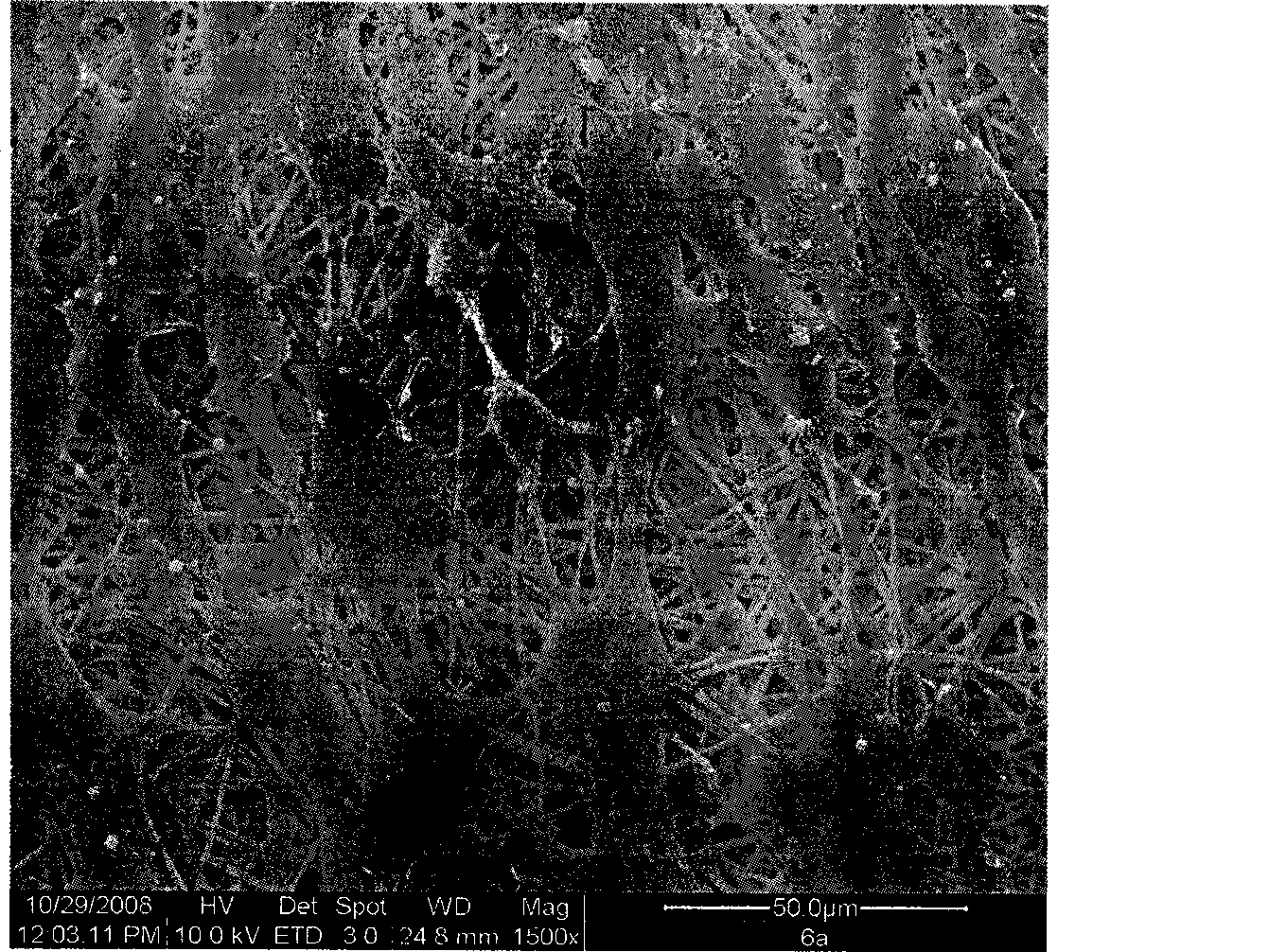

[0026] (2) Weigh 6g of silk fibroin with a balance, add it to 30ml of deionized water, swell at room temperature, stir and dissolve for 1-3 hours until the silk fibroin is completely dissolved, defoam for 1-3 hours until there are no bubbles in the solution, pour Into a flat mold of 5 x 5 cm, which was used in this embodiment to cast a film on a flat glass mold, volatilized for 2 days and then vacuum dried at 50°C for 7 hours to obtain a tissue isolation layer. At this time, scratch roughening with a probe to form staggered scratches with a depth of 1-10 microns on one side of the tissue isolation layer. Dissolve silk fibroin in deionized water to make a silk fibroin solution with a concentration of 30%, and then use electrospinning method to spray-spin on the above-mentioned scratched surface according to convention...

Embodiment 3

[0027] Embodiment 3: growth factor composite bioactive tissue regeneration film for bone tissue regeneration

[0028] (1) Silk fibroin is obtained in the same manner as in Example 1.

[0029] (2) Weigh 6g of silk fibroin with a balance, add it to 40ml of deionized water, swell at room temperature, stir and dissolve for 1-3 hours until the silk fibroin is completely dissolved, defoam for 1-3 hours until there are no bubbles in the solution, Pour into a 5 x 5 cm flat mold. In this embodiment, the flat glass mold is used to form a film by casting on a flat glass mold. After volatilization for 1 day, vacuum dry at 60° C. for 8 hours to obtain a tissue isolation layer. At this time, scratch roughening with a probe to form staggered scratches with a depth of 1-10 microns on one side of the tissue isolation layer.

[0030] (3) Add the freeze-dried powder of 0.5g bioactive factor recombinant human gene bone morphogenic protein to 100mL silk fibroin solution with a concentration of 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com