Glass protection film and manufacturing method thereof

A technology of glass protective film and microbeads, which is applied to flat products, other household appliances, conveyor objects, etc., and can solve problems such as high breakage rate, reduced glass cleanliness, and dust generated by paper pads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

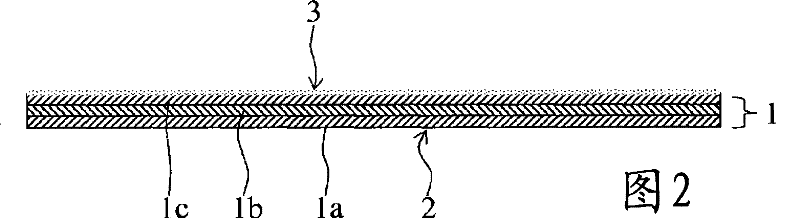

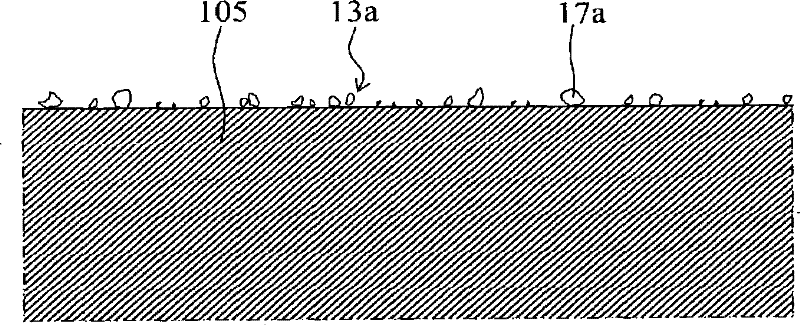

[0043] Using an extruder, the low-density polyethylene is melted and extruded into a pre-cured film that is slightly viscous. While the film is cured by pressing the film between a pair (two) of cooling rubber rollers, the microbeads are embedded on one surface of the film, thereby forming a non-sticky rough microbead surface. The microbeads are freely dropped on the cooling roller from the microbead supply device located above one of the two cooling rubber rollers, so that the microbeads are distributed thereon. The details are described below.

[0044] Substrate: low density polyethylene

[0045] Bead polymer: low density polyethylene

[0046] Melting point: 140°C

[0047] Film weight: 10g / m 2

[0048] Application environment: clean room

[0049] Diameter of cooling rubber roller: 80cm

[0050] Line speed: 90m / min

[0051] Particle size of polymer beads: 80μm~500μm

[0052] Bead distribution: 3g / m 2

[0053] The diameter of the bead release hole set at the bottom of the storage funnel: ...

Embodiment 2

[0058] The properties of the LCD glass protective film prepared in Example 1 are as follows:

[0059] i) The viscosity of the film: it is no different from the viscosity of a conventional protective film.

[0060] ii) Non-sticky properties: general properties: from light to 10g / m 2 The protruding microbeads of the membrane provide a non-sticky rough surface. When the glass plates are stacked, air is trapped between the microbeads protruding from the film, so that it can be ensured that the glass plates can be well separated from each other when they are transferred one by one.

[0061] iii) General characteristics: as thin as 10g / m 2 Its stable, non-sticky surface allows the treated film to be easily removed with a vacuum lifter. When the glass plates are stacked, the microbeads protruding from the membrane can act as elastic materials, helping to transport the glass plates more safely.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com