Cool end heat exchanger of pulse tube refrigerator

A technology of cold end heat exchanger and pulse tube refrigerator, applied in the direction of refrigerator, indirect heat exchanger, heat exchanger type, etc., can solve the problem of insufficient heat exchange area of cold end heat exchanger and poor performance of the whole refrigerator. Improve and other problems, to achieve the effect of simple structure, convenient assembly, and increased heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

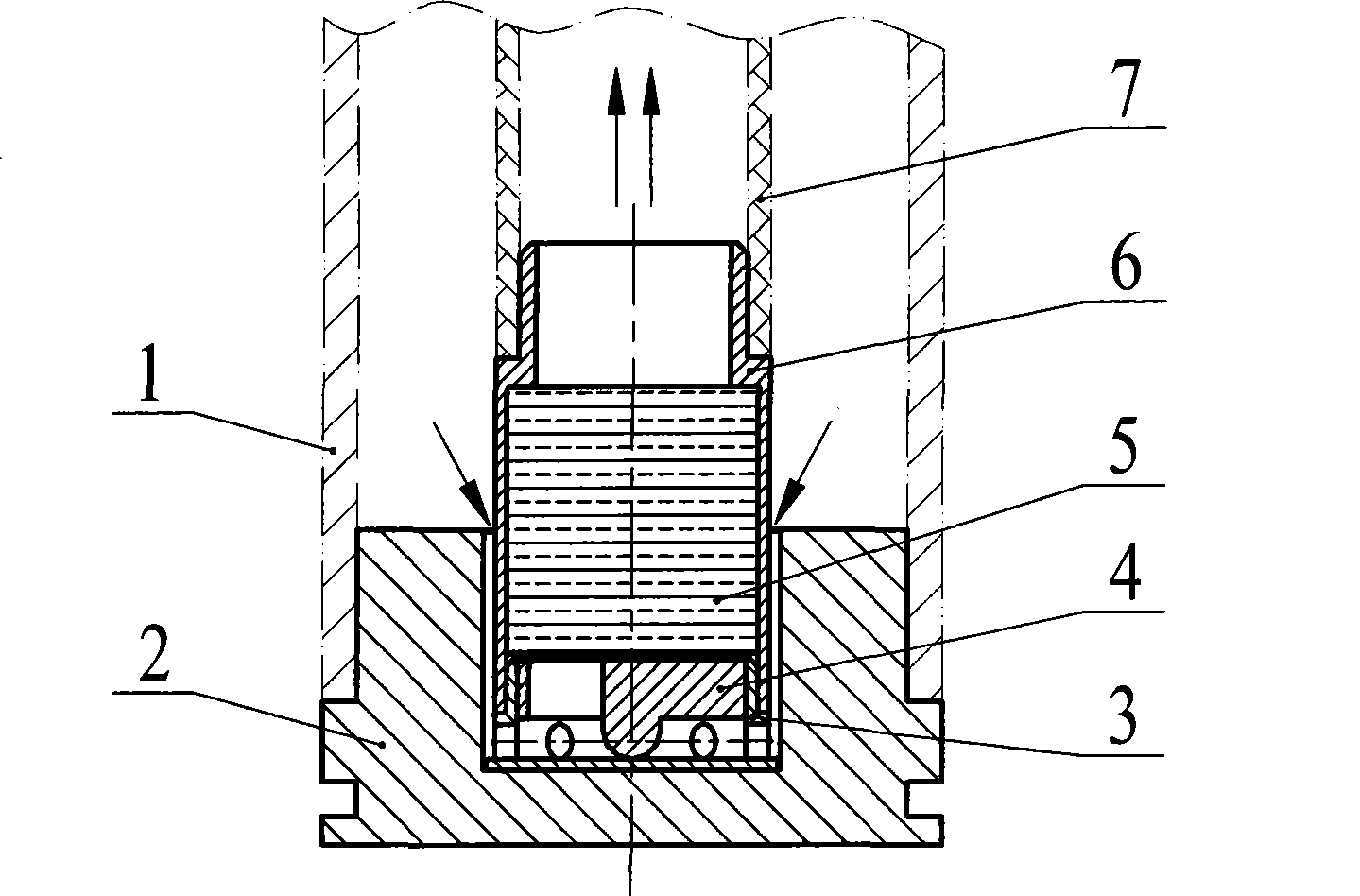

[0013] Such as figure 1 As shown, the present invention is made up of cold head (2), cold cap (3), cold cap deflector (4), wire mesh packing (5), heat exchanger (6). The cold cap deflector is put into the cold cap cavity, and its tapered end is supported on the bottom of the cold cap cavity. After the cold cap is combined with the cold cap deflector, the wire mesh filler filled in the heat exchanger is tightened and tightly fitted with the heat exchanger. The cold cap is placed in the cold head cavity to ensure that the bottom surface of the cold cap is closely attached to the bottom surface of the cold head inner cavity. The cold head and the regenerator (1) are welded and sealed as a whole, and the heat exchanger and the pulse tube (7) are connected by a tight fit.

[0014] The cold air flow from the cold end of the regenerator 1 passes through the annular gap formed by the inner wall of the cold head 2 and the outer wall of the cold cap 3 and the heat exchanger 6, and ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com