Composite aluminum oxide /erbium hydrogen resistance coating and preparation thereof

A composite alumina and composite coating technology, applied in coatings, metal material coating processes, gaseous chemical plating, etc., can solve problems affecting the density and hydrogen resistance of coating materials, high price, and affecting coating reliability. and other problems, to achieve the effect of improving the anti-hydrogen isotope diffusion performance, improving the particle characteristics, and improving the self-healing ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] First, on the base material of the liquid cladding, China Low Activation Matensitic Steel (CLAM), a Fe-Al metal transition layer is deposited by chemical vapor deposition (CVD). Using FeCl 3 and AlCl 3 As a precursor, steam treated at 500 °C (the molar ratio of Fe and Al is 1:1) and H 2 / Ar gas (H 2 accounted for 75%, Ar gas accounted for 1%) reacted in the reaction chamber of the CVD equipment, the deposition temperature was 600°C, and the chamber pressure was 300Pa. The obtained metal transition layer has a thickness of 2 μm.

[0037] Subsequently, Al was prepared on top of the metal transition layer 2 o 3 -Er 2 o 3 Composite coating. The preparation method of the composite coating is to use CVD equipment to pass 450°C AlCl into the reaction chamber 3 and Er-(tmhd) 3 Steam, Al / Er element molar ratio is 1 / 1. Simultaneously inject mixed gas O 2 / H 2 / Ar (where H 2 Accounting for 75% of the total air pressure, Ar gas accounts for 1% of the total air pressur...

Embodiment 2

[0042] Multilayer gradient composite coatings were prepared by CVD method on Chinese low activity martensitic steel (CLAM). Except for the steam composition containing metal elements, the CVD preparation conditions are basically the same as in Example 1.

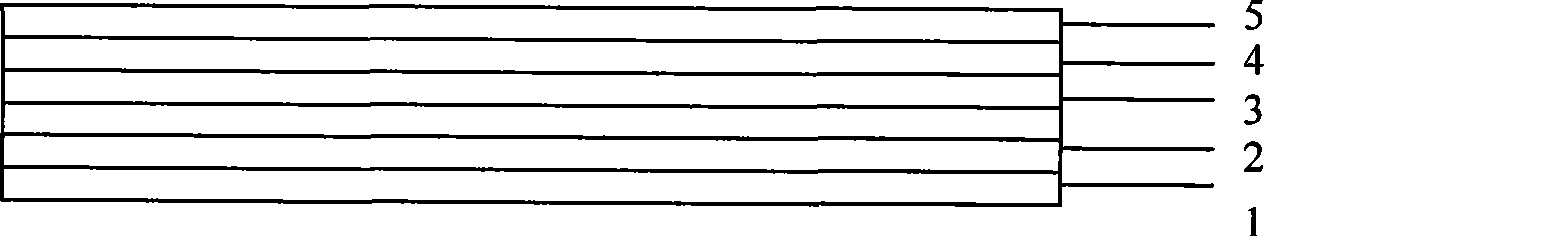

[0043] The prepared coating structure is as attached figure 2 As shown, where 1 is the base material CLAM steel; 2 is the metal transition layer prepared on the base material, with a thickness of 2 μm FeAl layer; 3 is Al 2 o 3 Coating; 4 is xAl in molar ratio x=0.5 2 o 3 -(1-x)Er 2 o 3 Composite coating; 5 is Er 2 o 3 Coating; the thickness of each coating of 3 to 5 is 3 μm.

[0044] After the prepared coating samples were subjected to multiple cooling and heating cycles from room temperature to 500 °C, the bonding between the coating, the transition layer and the substrate was firm without falling off.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com