Electrostatic dust remover for belt transfer station

A technology of electrostatic dust removal and transfer station, which is applied in the direction of transportation and packaging, external electrostatic separator, loading/unloading, etc., which can solve the problems of high maintenance cost, unsatisfactory dust removal effect, and large space occupation, so as to suppress dust spillage , The equipment occupies a small space and the effect of low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

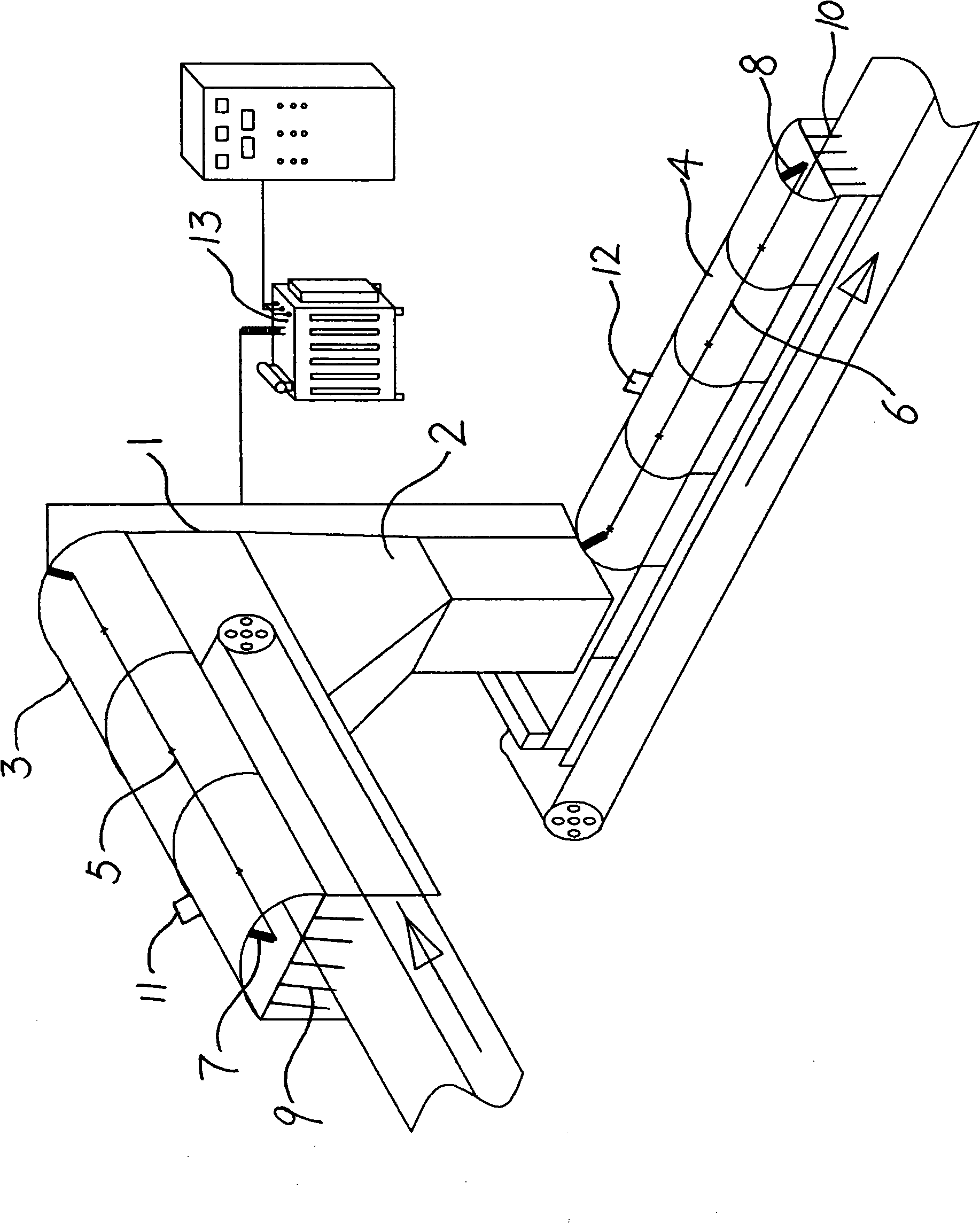

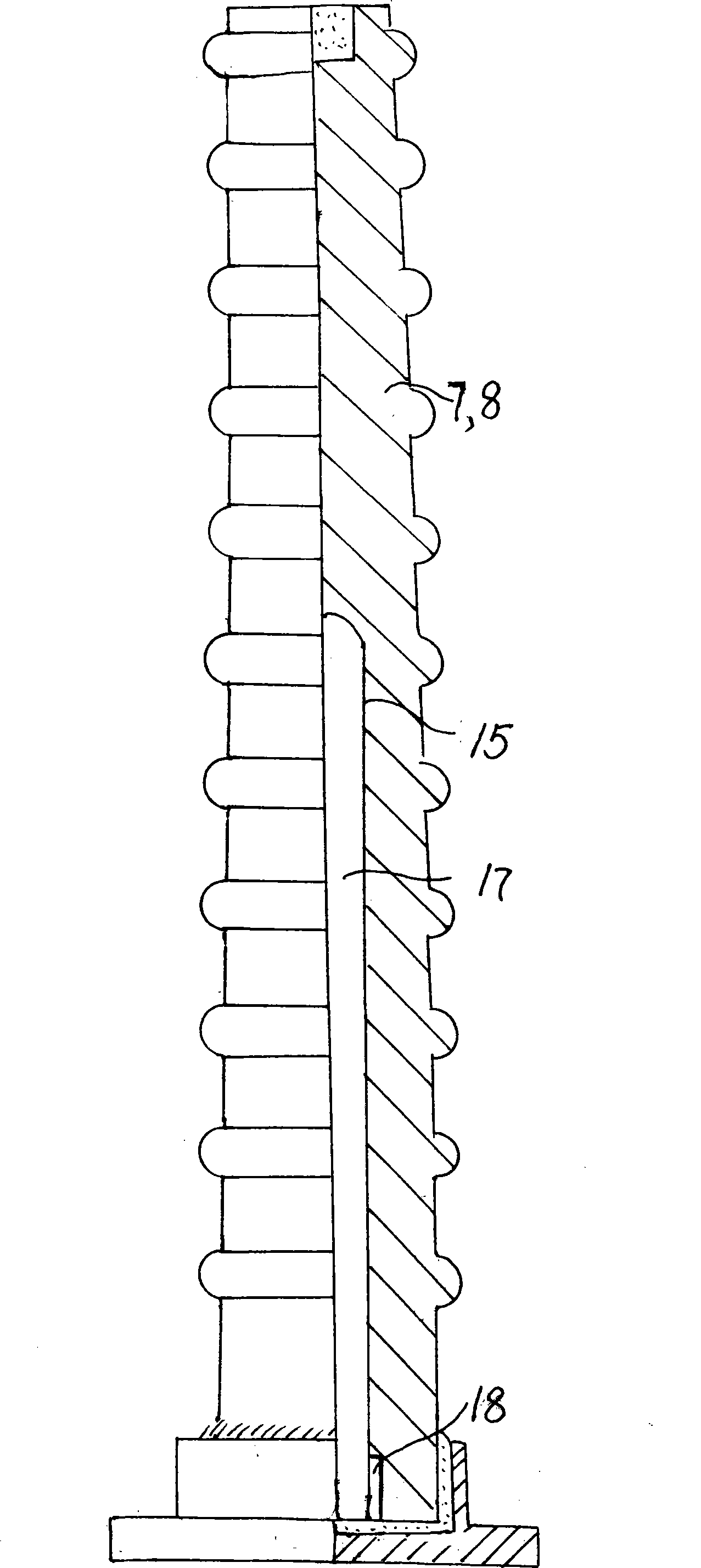

[0015] Such as figure 1 , 2 As shown, the belt transfer station electrostatic precipitator includes a transfer station body 1 equipped with a chute 2, a power supply part 13; a sealing cover 3, 4 is provided at the end area of the transfer part of the transfer station body 1; The covers 3 and 4 are equipped with electrostatic precipitating terminals; the output end of the power supply part 13 is connected to the input end of the electrostatic precipitating terminals. The electrostatic precipitator terminal of the present invention includes corona wires 5, 6 and insulators 7, 8 fixedly matched with them. The present invention is equipped with dust removal soft curtain 9,10 at the end of described sealing cover 3,4. Vibration mechanisms 11 and 12 are equipped on the sealing covers 3 and 4 of the present invention. Such as figure 2 As shown, the insulators 7 and 8 of the present invention can be equipped with a heating device assembly compartment 15; the heating device ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com