Filling materials for fire-proof system and its production method

A technology of filling materials and heat insulation materials, which can be used in building materials, chemical instruments and methods, fire protection, etc., and can solve the problem of no longer construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings. In these figures, the same reference numerals denote the same components.

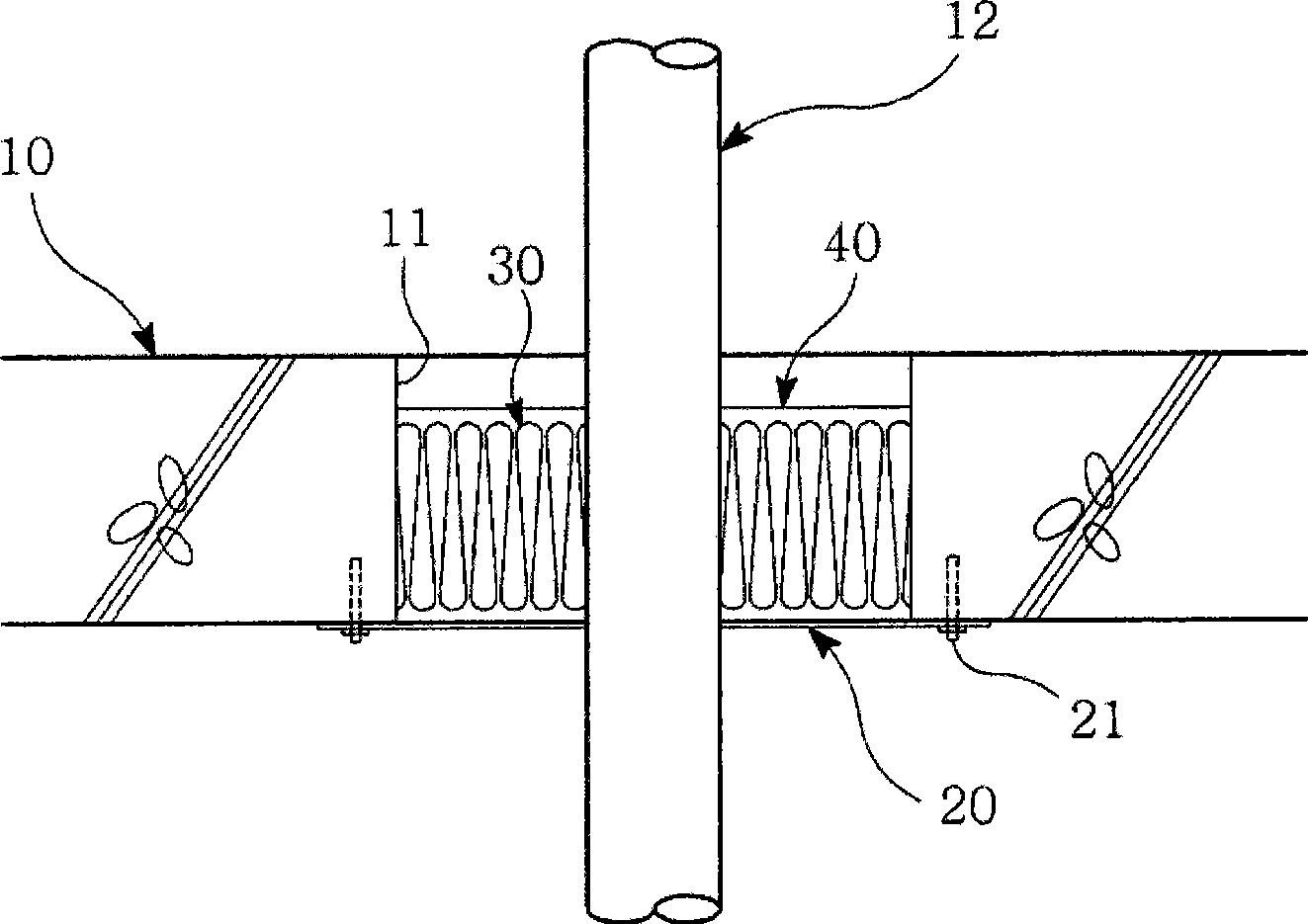

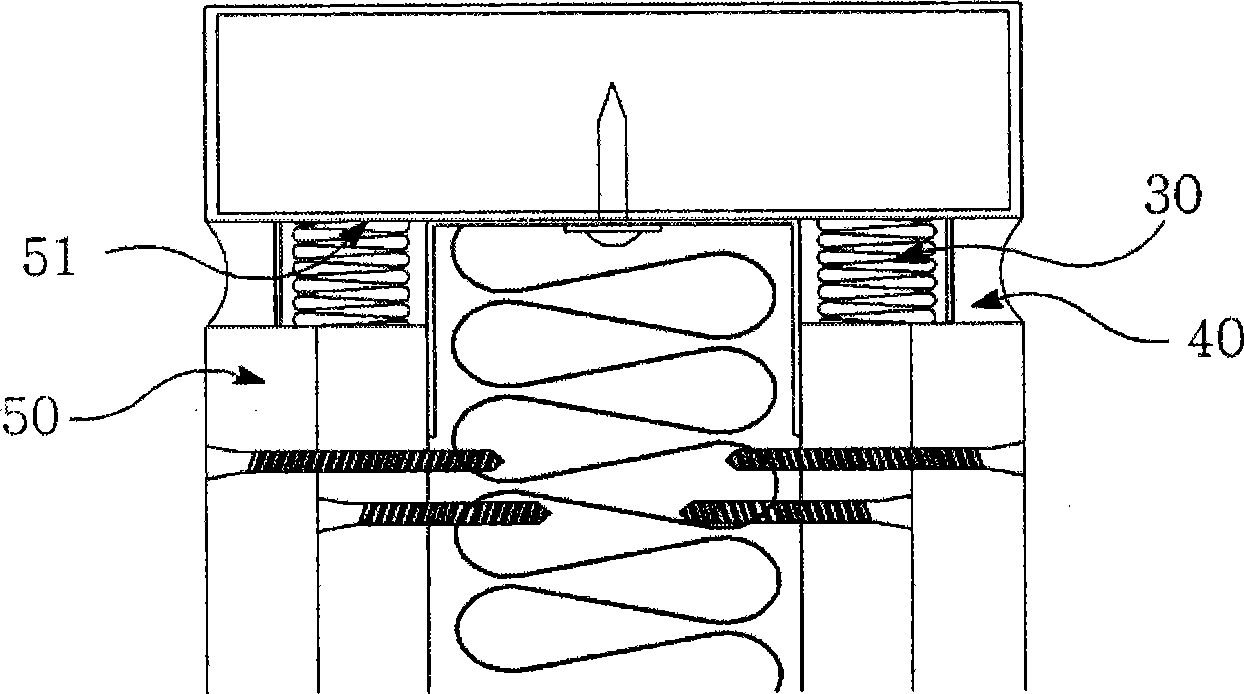

[0027] 1. Filling material for the fire-stop system in the fire-resistant partition

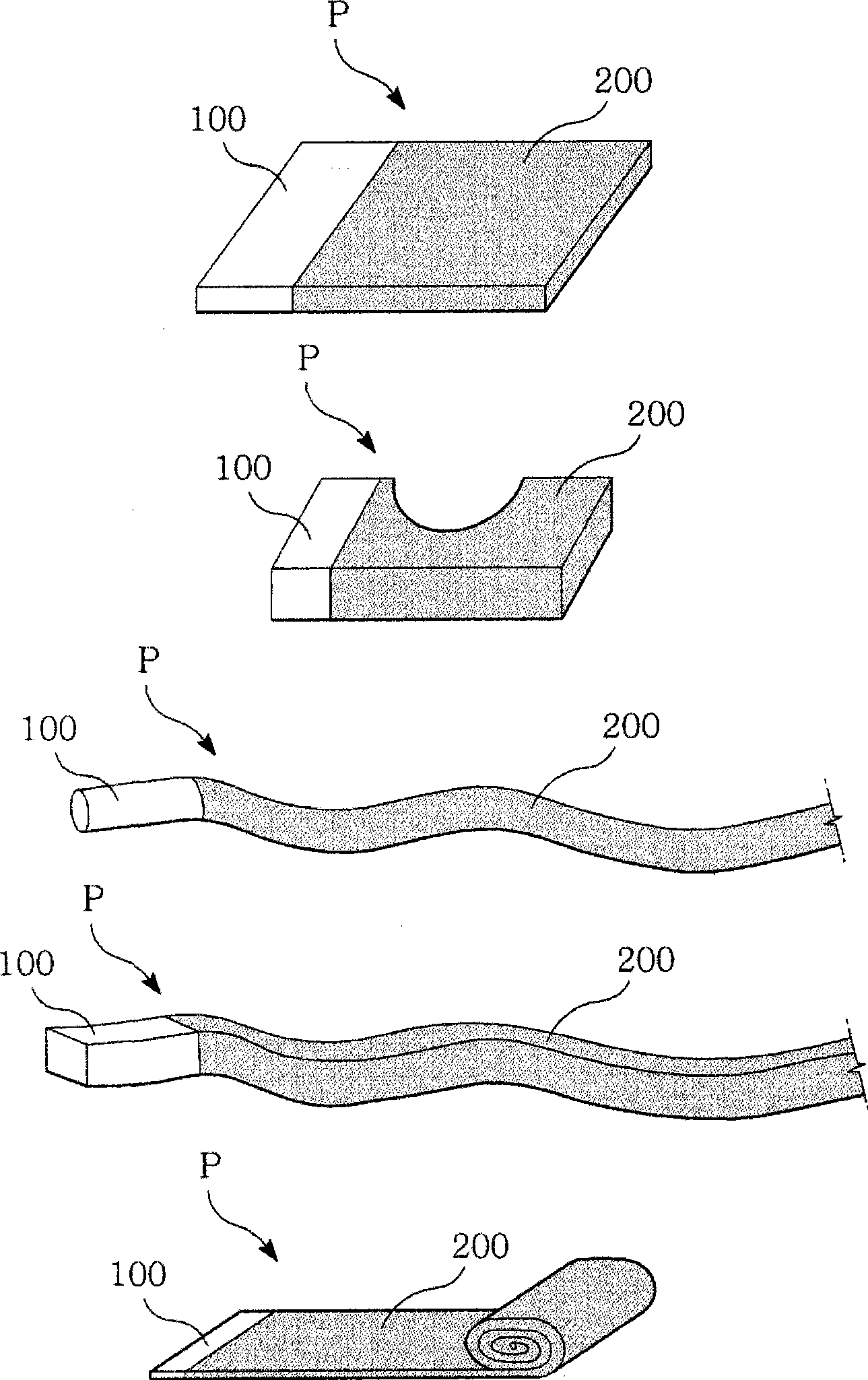

[0028] Figure 4 and 5 The filling material P for the firestop system is shown.

[0029] like Figure 4 and 5 As shown, the insulating material layer 100 is made of one selected from inorganic mineral wool, glass wool, Creak (ceramic) wool, vermiculite wool, and polyester-based insulating materials. Among them, mineral wool, glass wool, vermiculite wool and perlite wool are based on mineral fibers. The polyester-based heat insulating material may include non-woven fabric type SKY VIVA manufactured by SK Chemicals. In existing construction methods, insulation materials are cut and processed by workers at the building construction site, but in the present invention, such as image ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| compression ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com