Radiating device

A technology of heat dissipation device and heat pipe, which is applied in the direction of cooling/ventilation/heating transformation, electrical components, electric solid devices, etc., can solve the problems of increased manufacturing cost of radiators, and achieve the effect of overall manufacturing cost control and overall manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

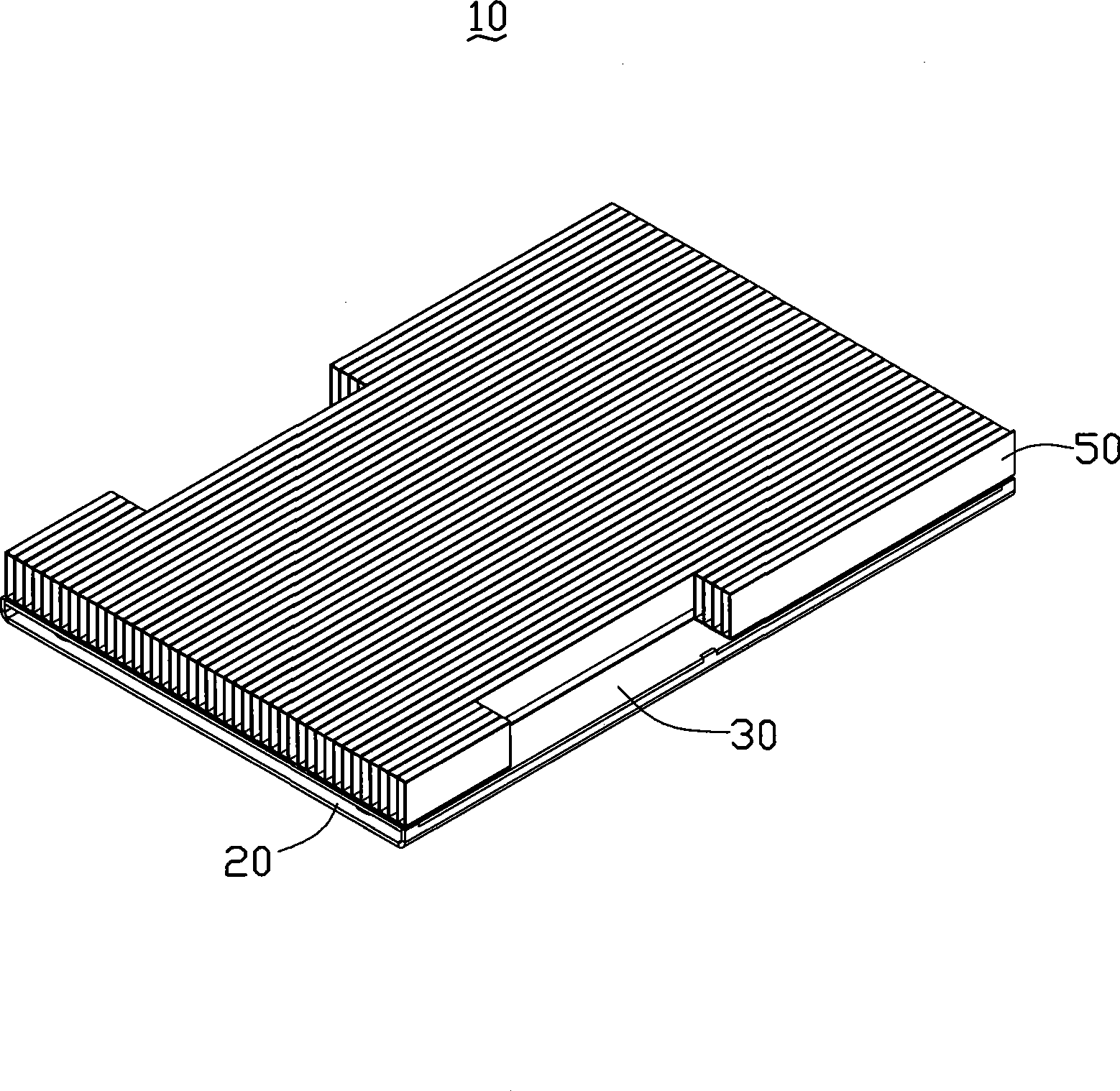

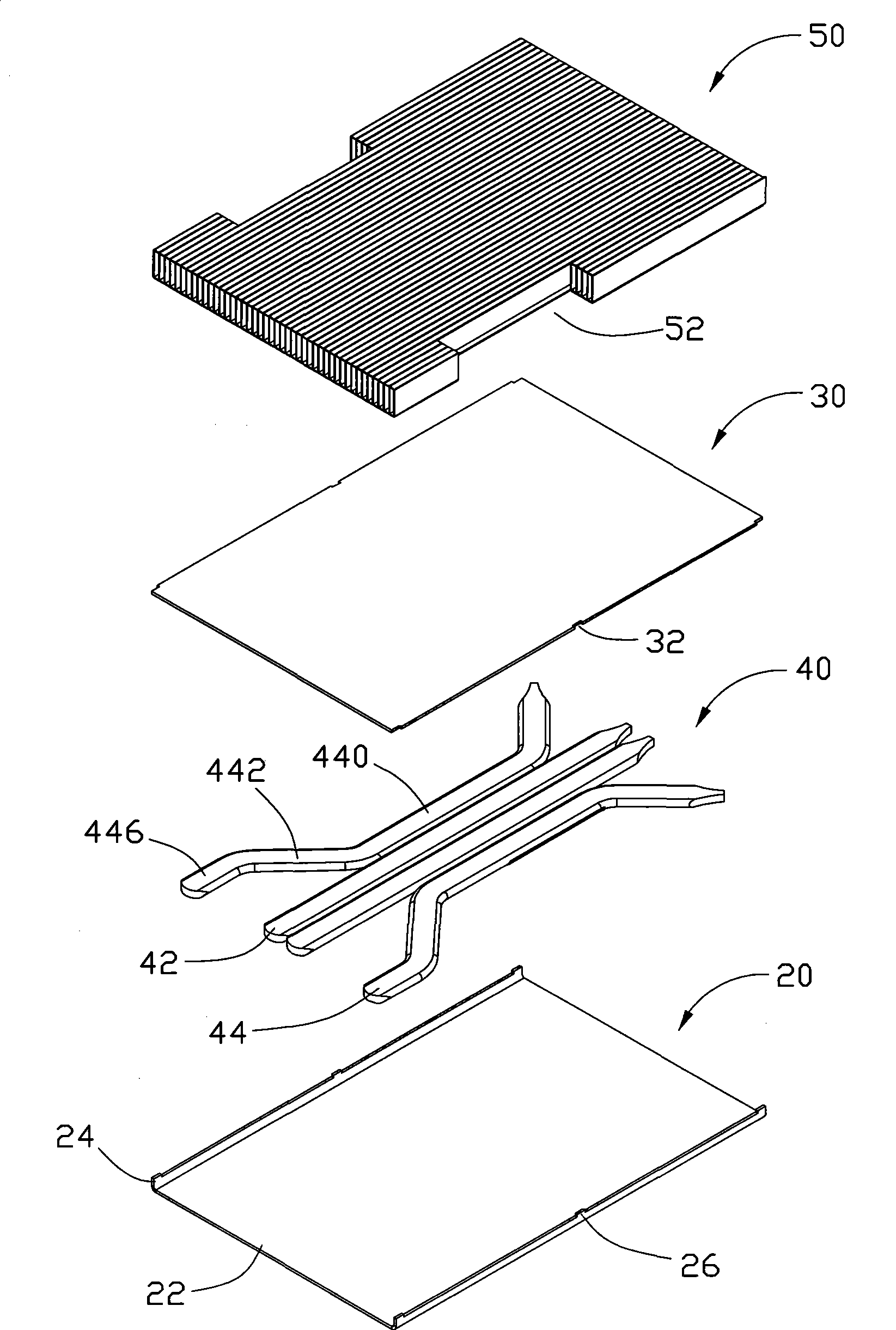

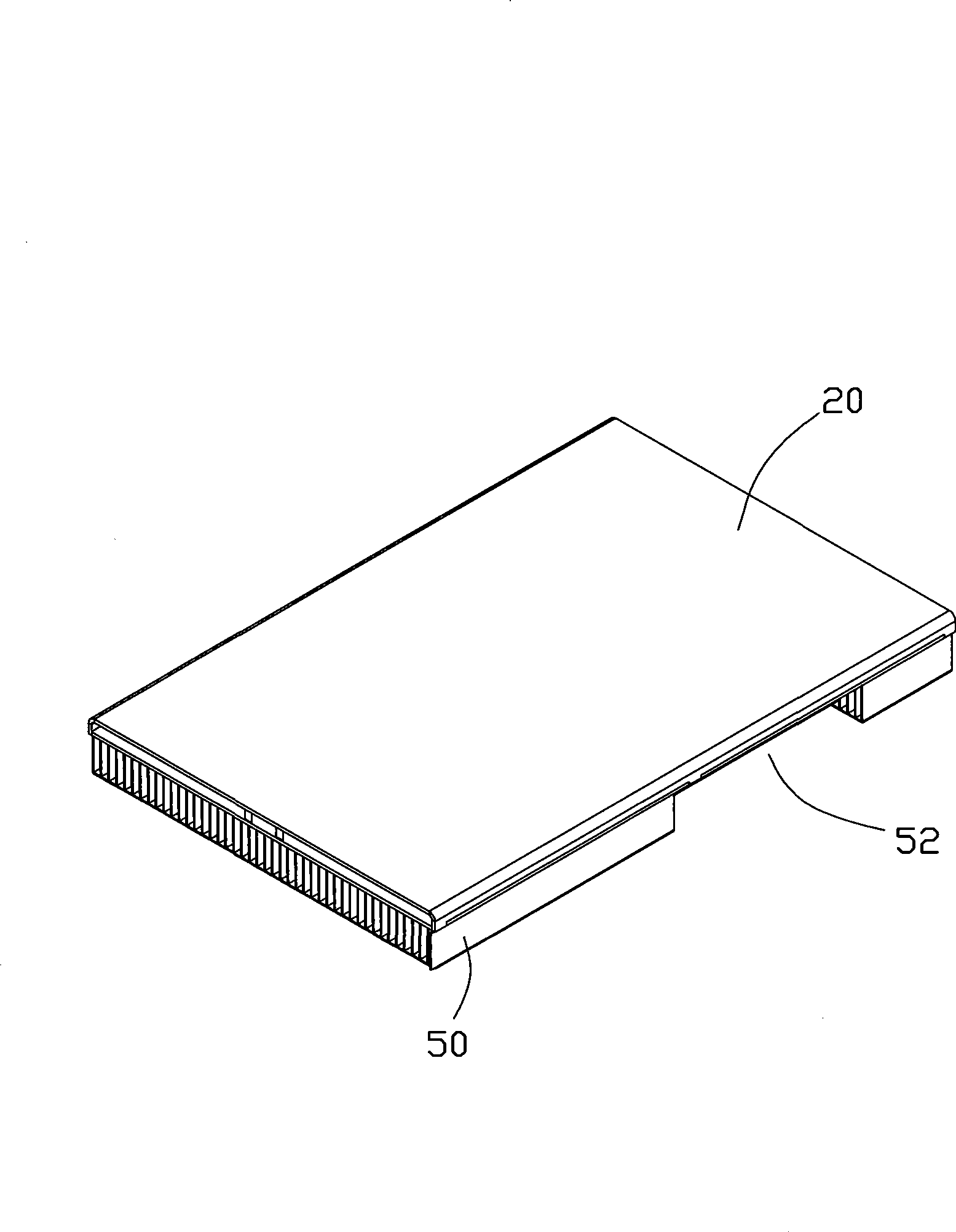

[0014] Such as figure 1 and 2 As shown, the heat dissipation device 10 of the present invention is used to dissipate heat from electronic components (not shown) mounted on a circuit board (not shown), and includes a base plate 20, a top plate 30 mounted on the base plate 20, a combination To the fin group 50 on the top plate 30 and a plurality of plate-shaped heat pipes 40 sandwiched between the bottom plate 20 and the top plate 30 .

[0015] Please also refer to Figure 4 , the bottom plate 20 is integrally formed by a metal plate, which is in contact with the electronic components to absorb the heat generated by the electronic components. The longitudinal section of the bottom plate 20 is roughly "U"-shaped, and it includes a flat rectangular plate body 22, two side walls 24 extending vertically upward from opposite sides of the plate body 22, and a plurality of rectangular plates respectively formed on the side walls 24. Positioning piece 26. Each side wall 24 is rectan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com