compressor

A compressor and oil technology, applied in the field of compressors, can solve the problems that the frictional motion pair of the compressor cannot be lubricated well, affects the reliability of the compressor, and the centrifugal force of the pump oil is not large enough to achieve good oil pumping effect, The effect of simple structure and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

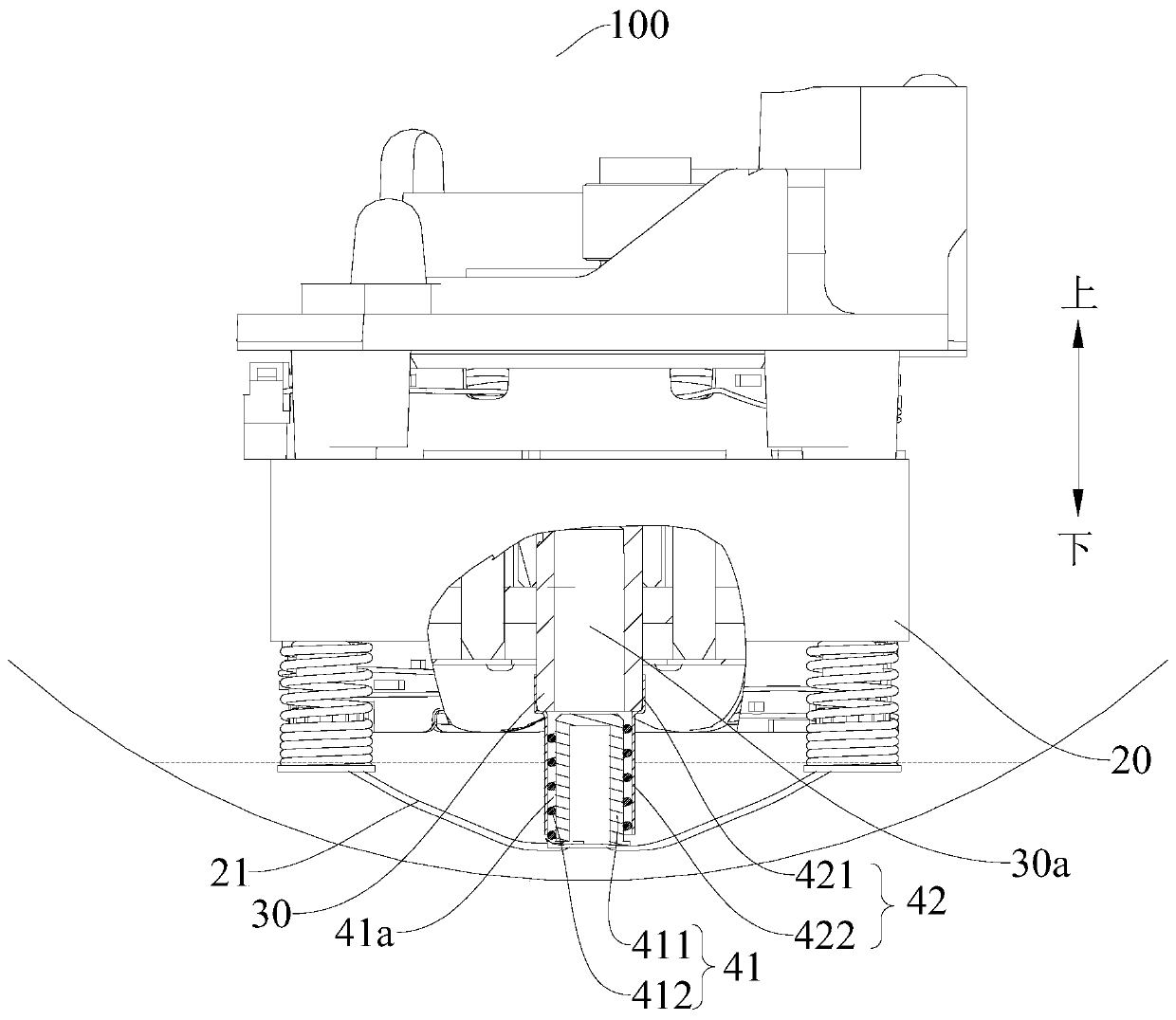

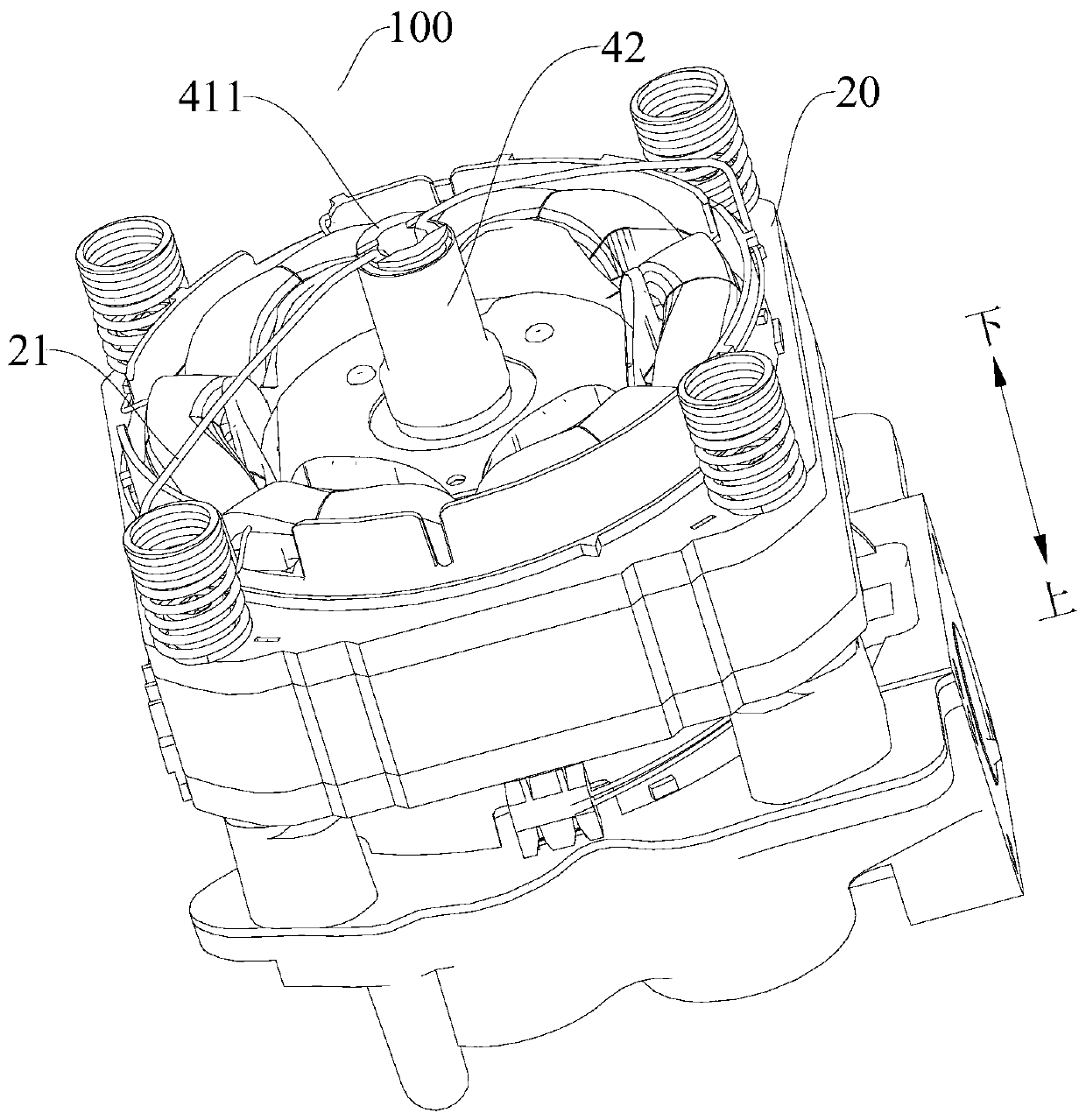

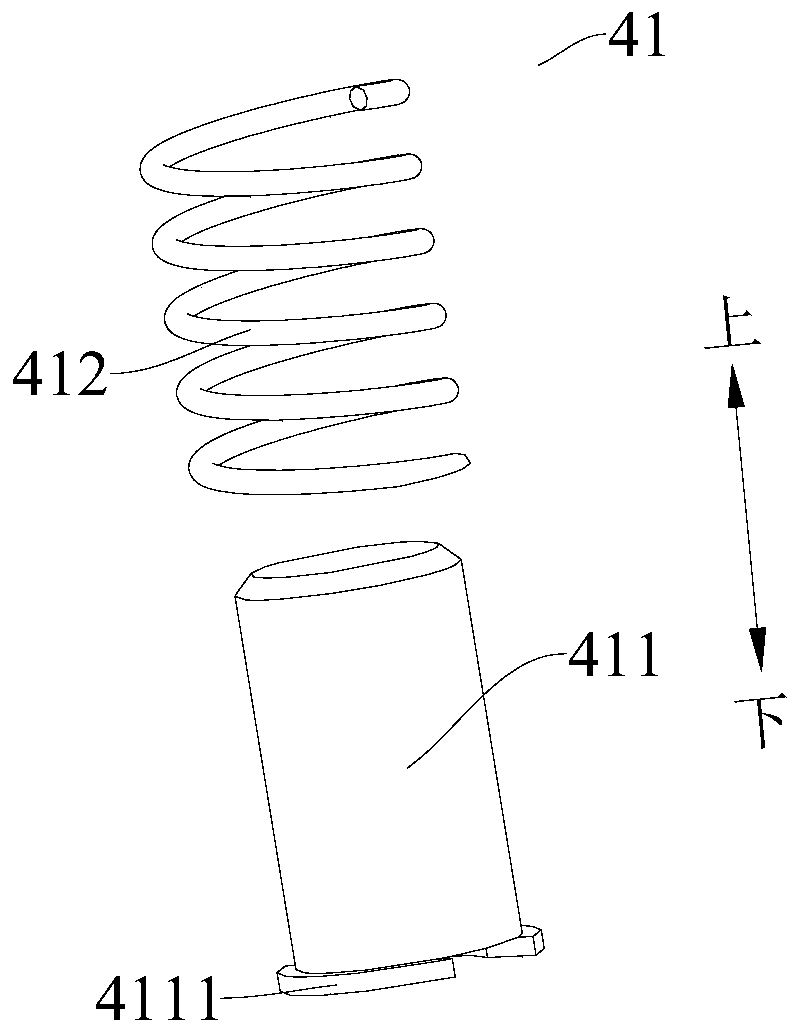

[0033] Embodiments of the invention are described in detail below, examples of which are illustrated in the accompanying drawings. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

[0034] The oil pumping device in the related art uses traditional centrifugal oil pump components to pump oil. The disadvantage of this oil pumping method is that when the compressor is running at a low speed, the centrifugal force of the pump oil is not large enough, causing the compressor to rotate at a low frequency. When the oil pump capacity is insufficient, the frictional motion pairs of the compressor cannot be lubricated well, which affects the reliability of the compressor.

[0035] Also, the compressor in the related art uses the screw principle of lubricating oil to pump oil. The oil pump system is fixedly connected with a cylindrical oil pump housing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com