Double-silver low-emissivity glass and production process thereof

A low-emissivity glass and production process technology, applied in coating and other directions, can solve the problems of high production cost and complex structure, and achieve the effects of low production cost, good heat transfer performance and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

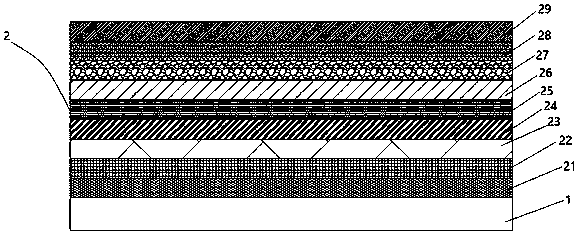

[0027] refer to figure 1 , a kind of double-silver low-emissivity glass of the present invention, described double-silver low-emissivity glass comprises: glass substrate 1; The surface of described glass substrate 1 is provided with double-silver low-emission film layer 2, and described double-silver low-emission The radiation film layer 2 includes the first SnO arranged on one side of the glass substrate 1 sequentially from the inside to the outside. x Layer 21, first ZnO x layer 22, first AgTi layer 23, second ZnO x Layer 24, the second SnO x Layer 25, third ZnO x layer 26, second AgTi layer 27, fourth ZnO x layer 28 and the third SnO x Layer 29; the double-silver low-emissivity film layer is coated on the surface of the glass substrate 1 by a magnetron sputtering process.

[0028] Further, the glass substrate 1 is white glass, and the thickness of the glass substrate is 5-10mm.

[0029] Further, the shading coefficient of the double-silver low-e glass is ≤0.48.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com