Continuous plasma flow ignition exciter

A technology of plasma flow and exciter, applied in combustion ignition, incandescent ignition, machine/engine, etc., can solve the problem of serious electromagnetic radiation, affecting the performance and life of ignition device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in more detail below in conjunction with accompanying drawing example:

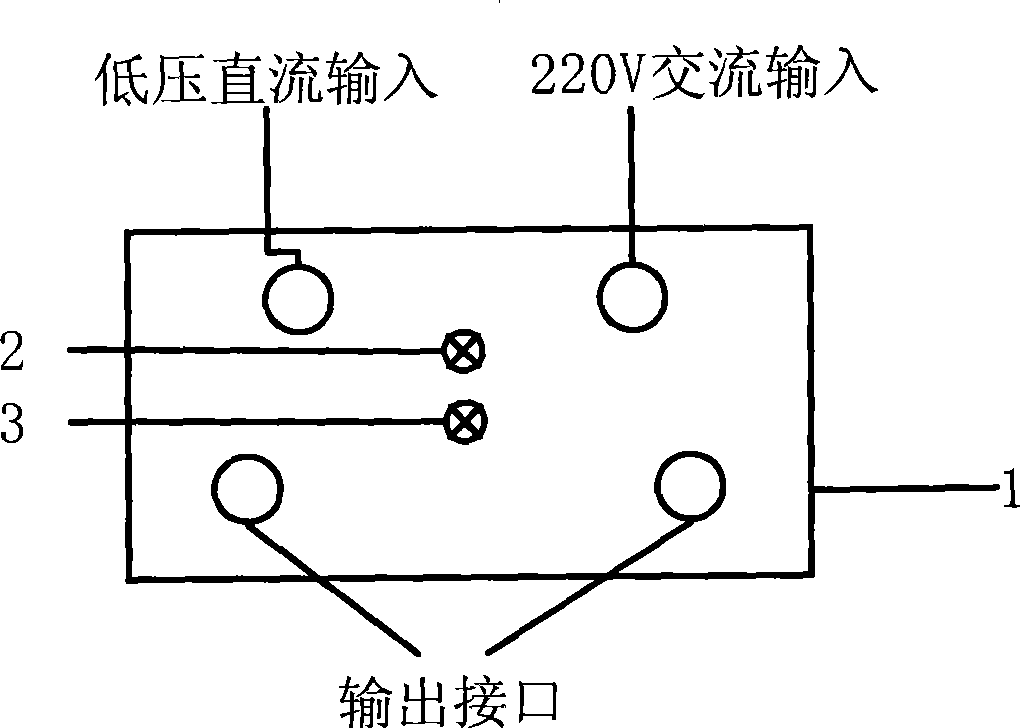

[0023] combine figure 1 , figure 1 It is a schematic diagram of the external connection of the continuous plasma flow ignition actuator of the present invention. Its external interface and indicator light mainly include: a 220V AC input interface, a low-voltage DC control input interface, a working indicator light, a fault indicator light, and an output interface. The number of output interfaces of the exciter can be determined according to the number of ignition sources determined by factors such as gas turbine power and fuel. According to the number of output interfaces, the exciter module can be expanded. For example, if one exciter is designed to have 2 outputs, if 4 ignition sources are required, two exciters, 4 sets of plasma generators and high-voltage ignition cables are equipped.

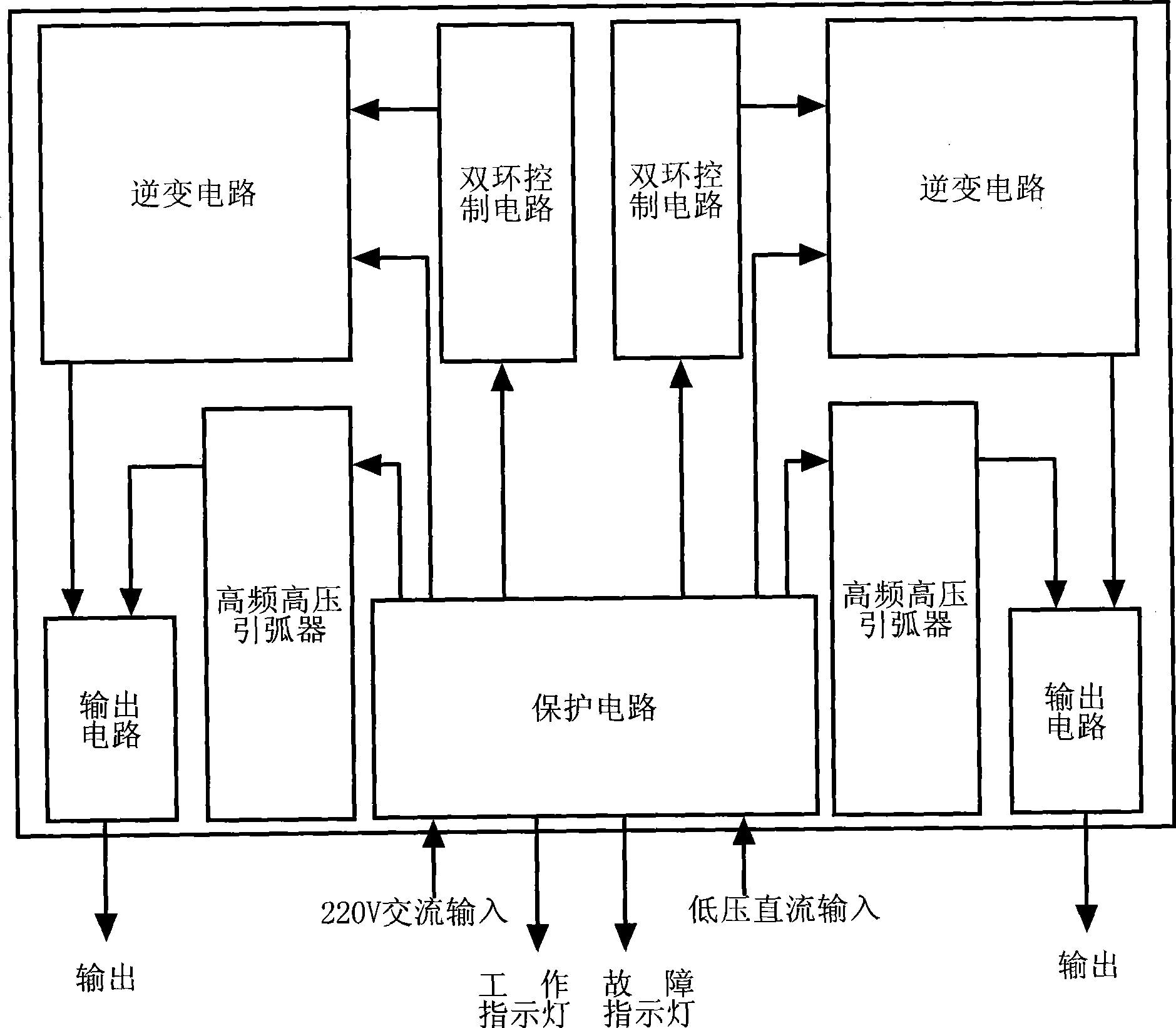

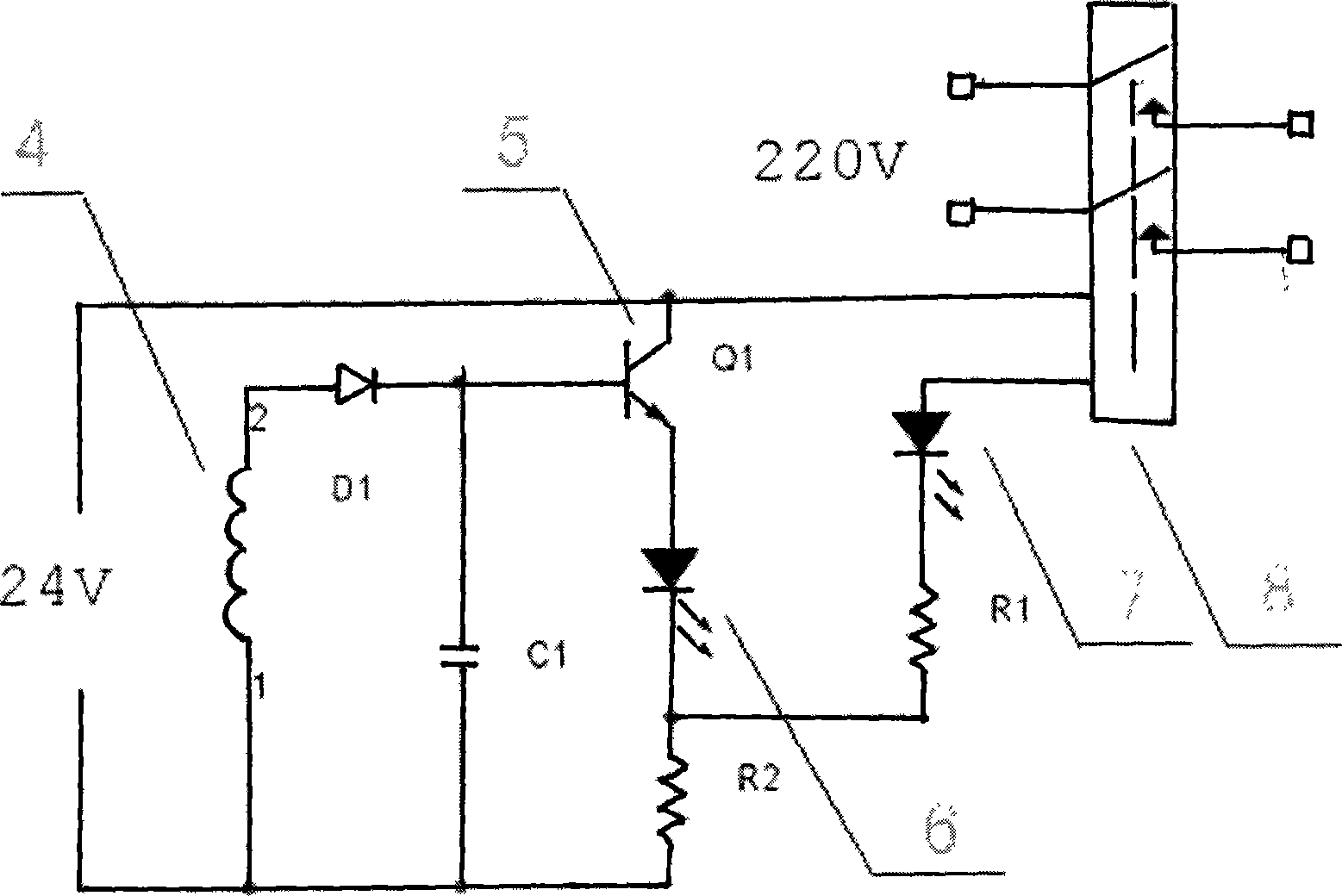

[0024] figure 2 It is a schematic diagram of the internal structure m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com