Low-discharge two-stroke gasoline engine

A two-stroke, low-emission technology, used in mechanical equipment, combustion engines, machines/engines, etc., can solve the problems of overheating, increase costs, and contain harmful components, and achieve the effect of increasing airflow speed and reducing opening area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

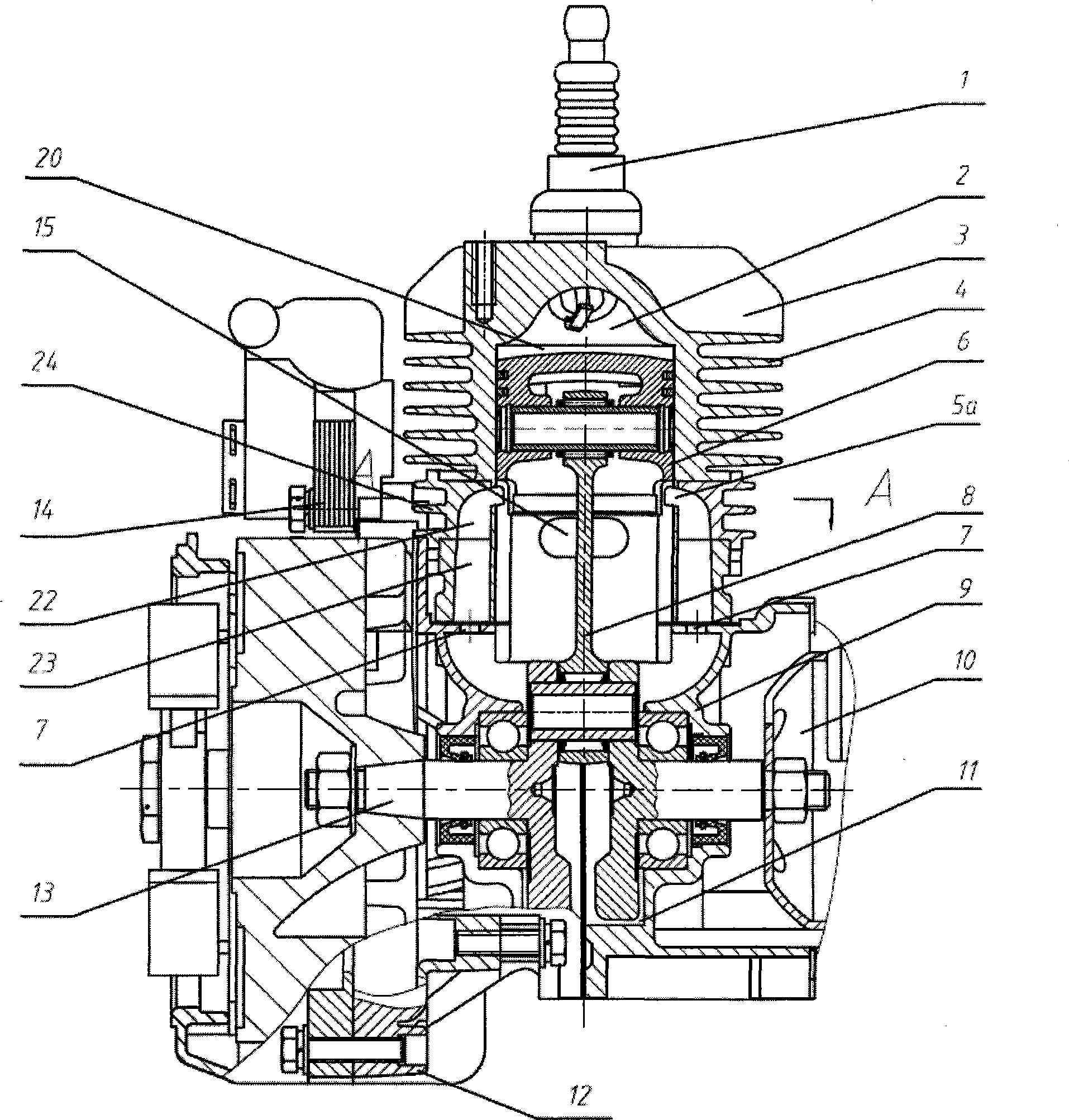

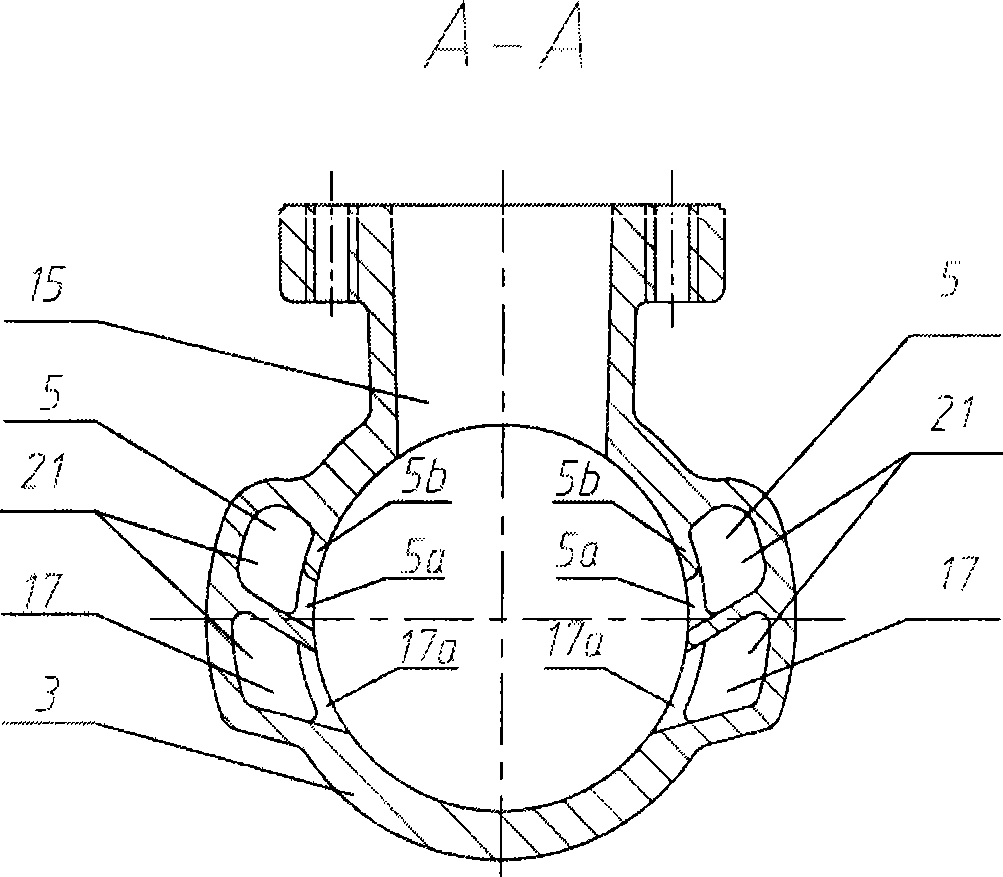

[0024] Such as figure 1 , figure 2 , image 3 , Figure 4 Shown, according to the two-stroke gasoline engine of the present invention, comprise cylinder block 3, cylinder chamber 20, the scavenging passage 21 that is made up of the upper sweeping passage 23 on the cylinder block 3 and the lower sweeping passage 22 on the end cap, front half crankshaft Crankshaft chamber assembly composed of box 12 and rear half crankcase 9, motion assembly composed of crankshaft 13, connecting rod 8, piston 6, etc., ignition system composed of magneto 14, spark plug 1, etc., carburetor (not shown in the figure), starter Parts such as dial 10.

[0025] Air inlet 16, exhaust port 15, scavenging air passage 21 (comprising air scavenging passage one 5, air scavenging passage two 17, air scavenging outlet 1 5a, air scavenging outlet 2 17a) are designed on the trunk part of the cylinder body, Wherein the position of air inlet 16 in the vertical direction is lower than exhaust port 15 and scaven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com