Hydraulic support for large-mining height caving coal

A technology of hydraulic support and top coal caving, which is applied in mine roof support, mining equipment, earthwork drilling and mining, etc. It can solve the problems of poor torsional performance, increased labor intensity, and occupying the installation space of double rear connecting rods, etc., to achieve stability Good performance, improved work efficiency, and a reasonable ratio of extraction and discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

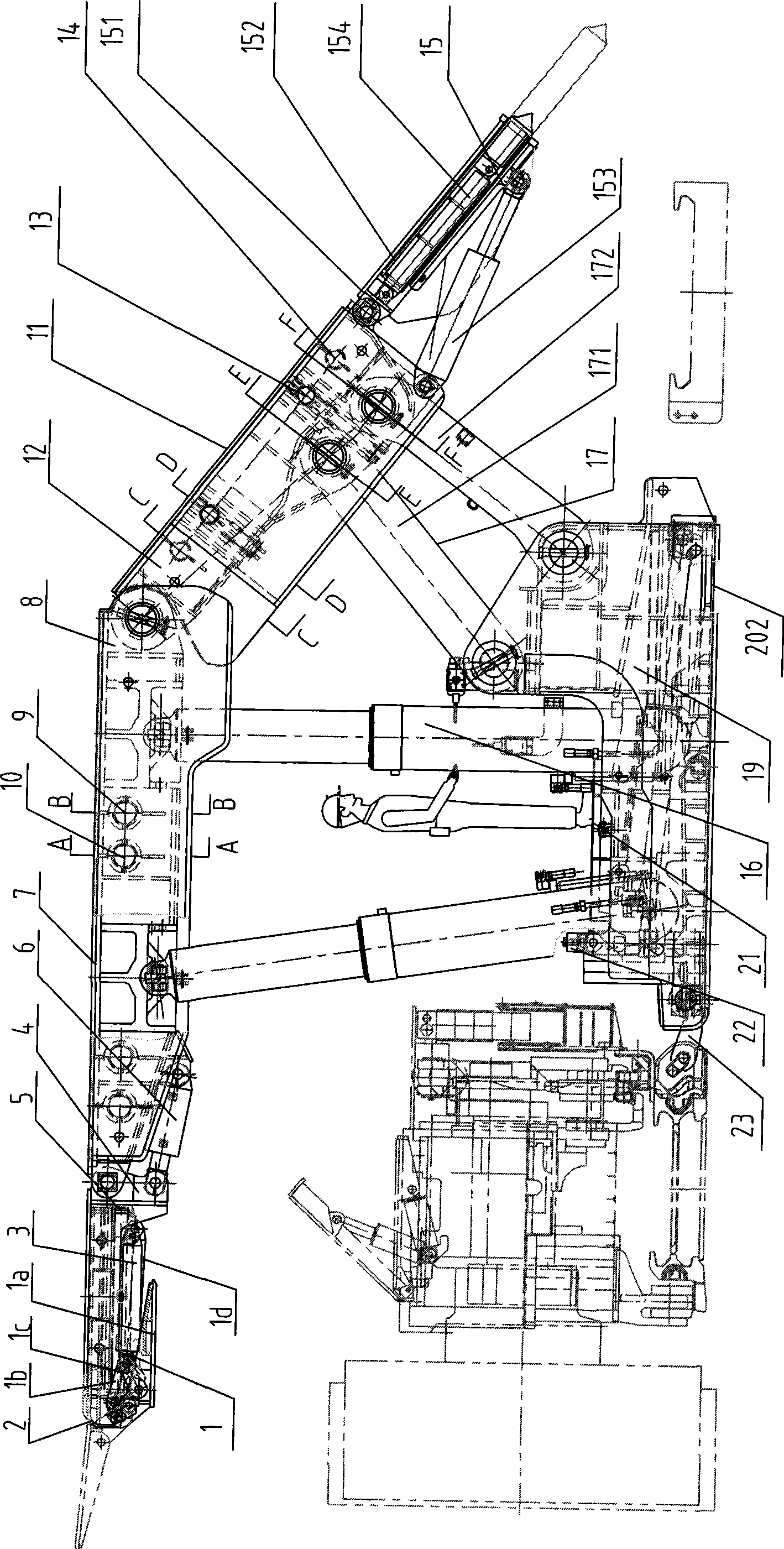

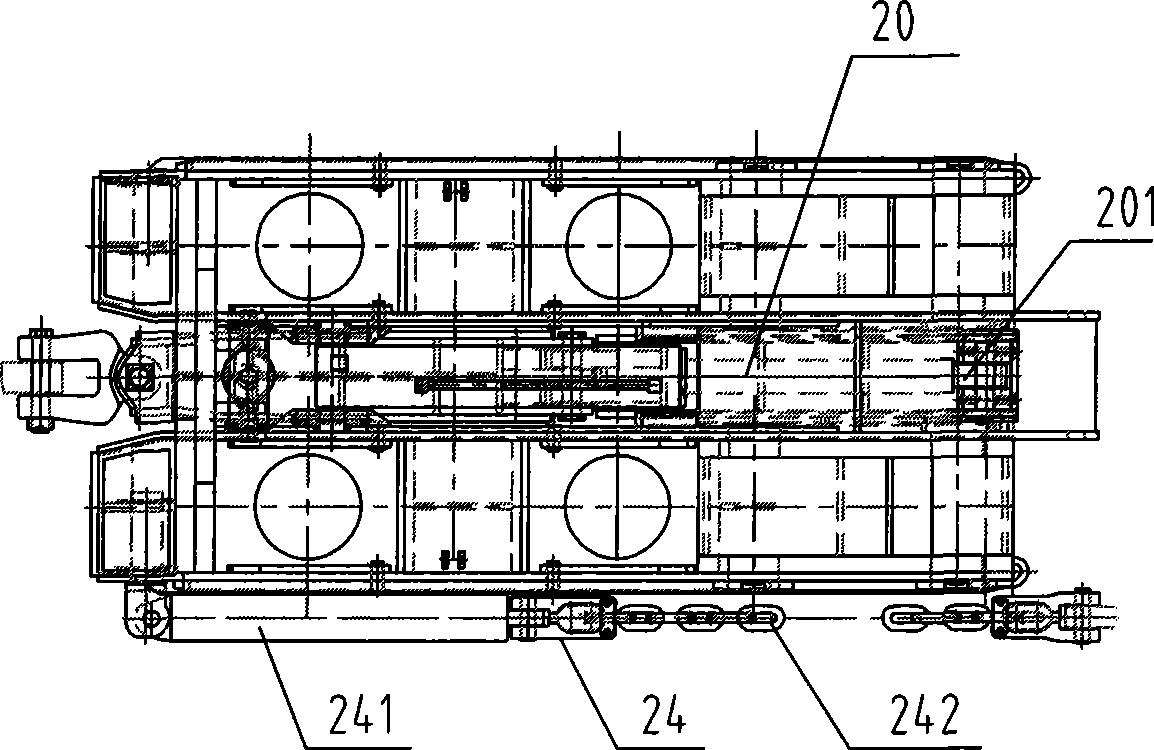

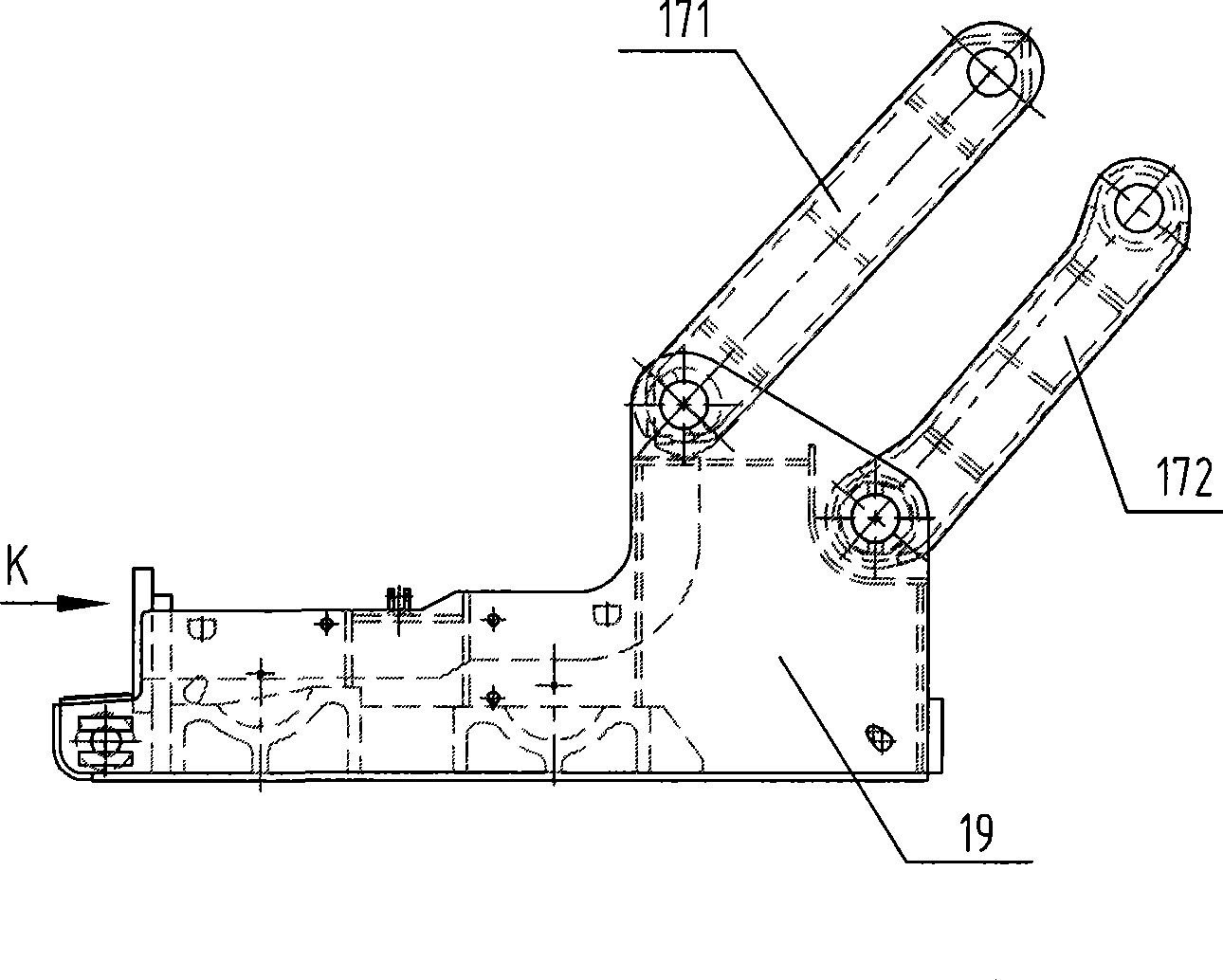

[0026] see figure 1 , figure 2 , Figure 4 , Figure 7 , Figure 8 , Figure 9 , Figure 10As shown: the hydraulic support for large mining and high-level top-coal caving is used in the large-scale high-level top-coal caving working face, which mainly includes a column 16 and a top beam 7 and a base 19 respectively hinged at both ends. The column 16 makes the maximum height of the support reach 4.0 meters to 5.2 meters, four columns 16 are used, and the four columns 16 are arranged symmetrically in two rows. There is a passage between the columns 16; one side of the top beam 7 is provided with a top beam side guard plate 8, which is used for sealing and anti-falling between the frames. A side push mechanism a9 is hinged between the top beam 7 and the top beam side guard plate 8, and the top beam side guard plate 8 is hinged with the side push jack a91 inside the top beam 7 through the guide rod a92, and is realized by means of the push of the side push jack a91. Telesco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com