Carbon beaverboard anchorage

A carbon fiber board and anchor technology, which is applied in the field of anchors to achieve the effects of sufficient contact, increased friction and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

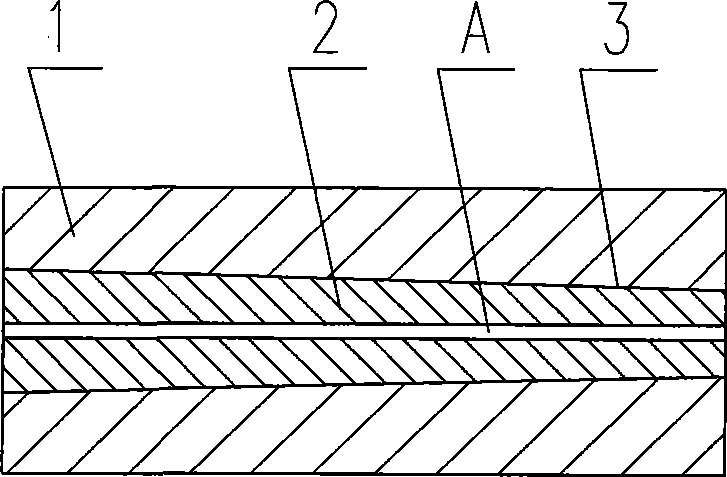

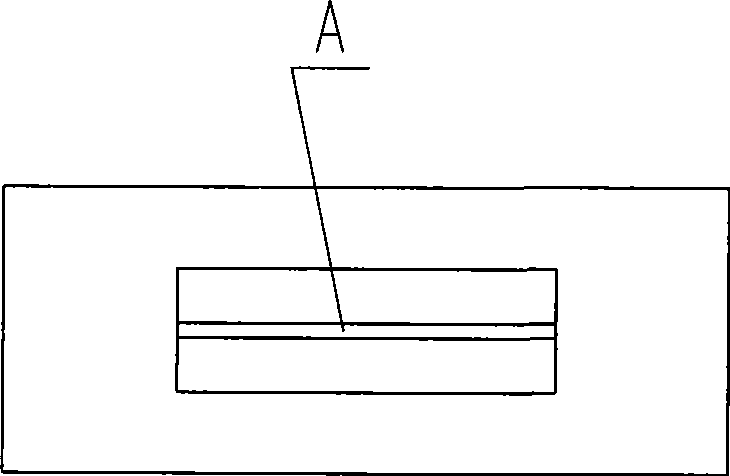

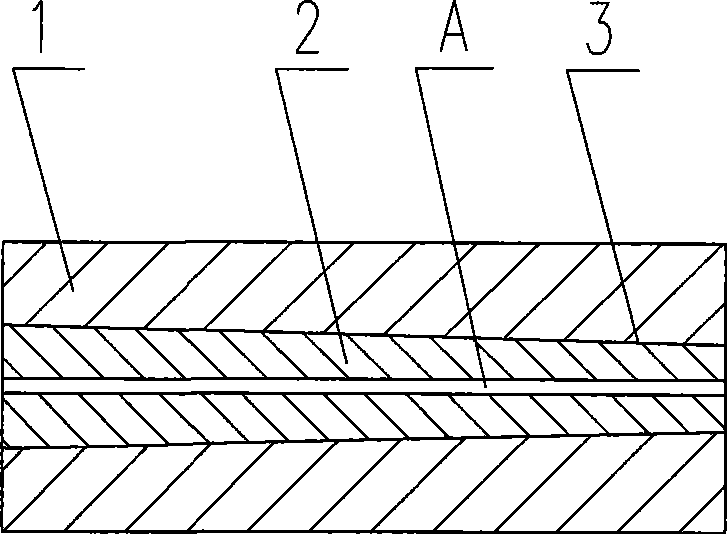

[0035] A carbon fiber plate anchor, the anchor plate 1 is a cylinder with a rectangular cross section, and a wedge-shaped through hole with a rectangular cross section and a tapered longitudinal section is opened inside, and the clip 2 is a two-piece wedge-shaped block , the closed shape after it is wedged into the anchor plate to clamp the carbon fiber plate is closely matched with the wedge-shaped through-hole with a rectangular cross-section and a tapered longitudinal section in the anchor plate (see Figure 1 ~ Figure 2 ).

Embodiment 2

[0037] A carbon fiber plate anchor, the anchor plate 1 is a cylinder with an elliptical cross-section, and a wedge-shaped through-hole with a rectangular cross-section and a taper in the longitudinal section is opened inside, and the clip is a two-piece wedge-shaped block , the closed shape after it is wedged into the anchor plate to clamp the carbon fiber plate is closely matched with the wedge-shaped through-hole with a rectangular cross-section and a tapered longitudinal section in the anchor plate (see Figure 3 ~ Figure 4 ).

Embodiment 3

[0039] A carbon fiber plate anchor, the anchor plate is a cylinder with a circular cross section, and a wedge-shaped through hole with a rectangular cross section and a taper in the longitudinal section is opened inside, and the clip is a two-piece wedge block. The closed shape after it is wedged into the anchor plate to clamp the carbon fiber plate is closely matched with the wedge-shaped through hole with a rectangular cross section and a tapered longitudinal section inside the anchor plate (see Figure 5 ~ Figure 6 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com