Method for continuous production of sulphur chlorination isobutene

A technology for chlorinating isobutene and isobutene by sulfur, which is applied in chemical instruments and methods, preparation of organic compounds, organic chemistry and other directions, can solve the problems of dark product color, complicated process and reduced yield, and saves process steps and processes. Simple process and light-colored product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

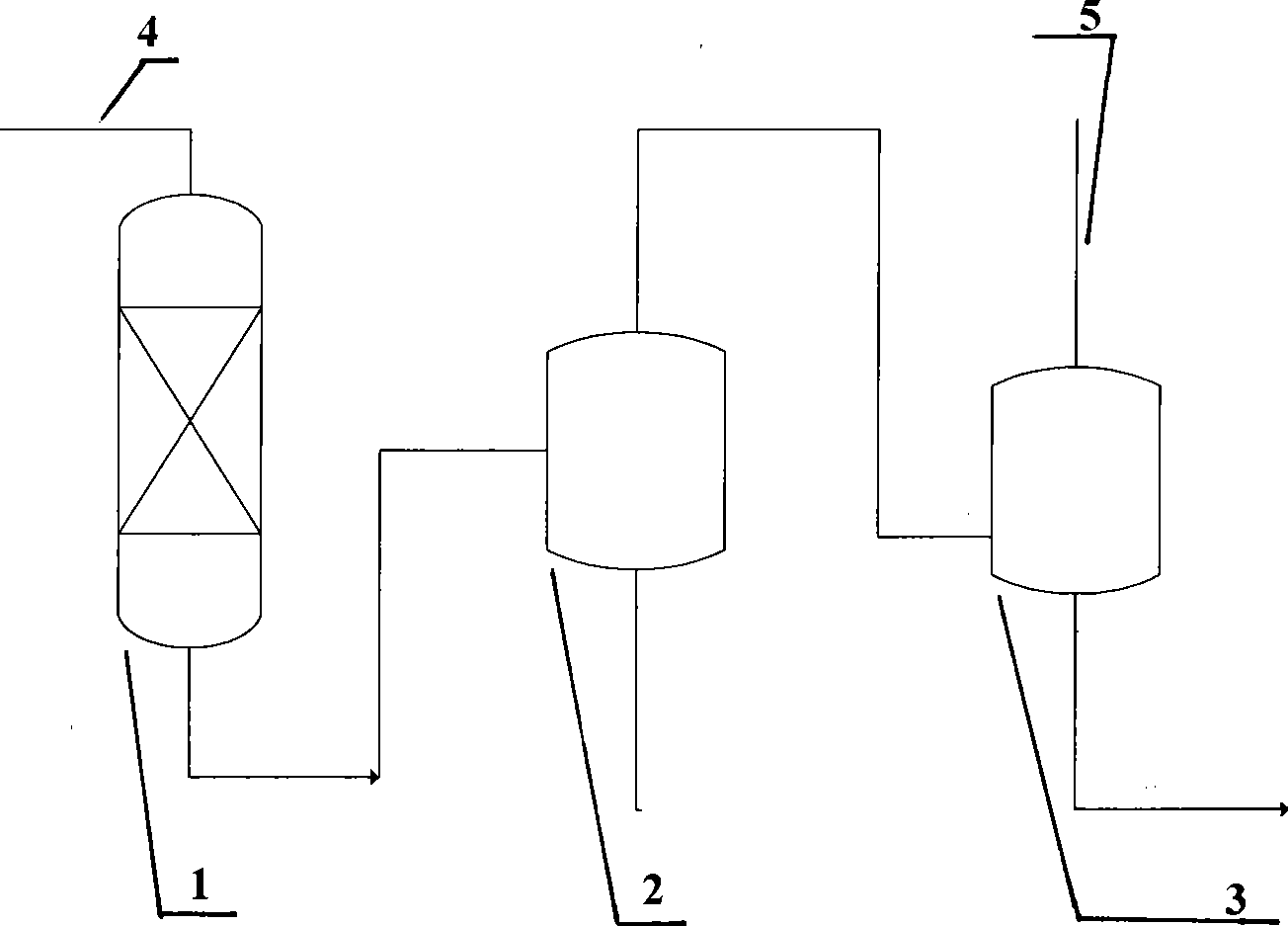

Image

Examples

Embodiment 1

[0026] The inner diameter of the cracking reactor is φ37mm, the height of the reaction catalyst bed is 1200mm, and 1600 milliliters of cracking catalyst is installed inside. The cracking catalyst is an acidic cation exchange resin (produced by Dandong Mingzhu Special Resin Co., Ltd., DWN).

[0027] The isobutylene recovery tower has an inner diameter of φ14mm, a packing of φ3mm inside, and a filling height of 35mm.

[0028] The sulfur chlorination reactor has an inner diameter of φ39mm, the reaction catalyst is Lewis acid, and the reactor is filled with 3500 grams of inert packing.

[0029] Firstly, the MTBE cracking reaction is carried out in the cracking reactor, and the reaction is carried out under the conditions of pressure 0.5MPa and temperature 155°C, and the MTBE feeding space velocity is 4h -1 The reacted mixture enters the isobutene recovery tower with an operating pressure of 0.4 MPa, a tower top temperature of 39° C. and a reflux ratio of 0.8. From the top of the ...

Embodiment 2

[0032] Operating equipment is the same as embodiment 1

[0033] Firstly, the MTBE cleavage reaction is carried out in the cleavage reactor. The reaction was carried out at a pressure of 0.30 MPa and a temperature of 180° C., and the MTBE feed rate was 5500 g / hour.

[0034] The reacted mixture enters the isobutene recovery tower with an operating pressure of 0.6 MPa, a tower top temperature of 40°C, and a reflux ratio of 1.8. 3445.1 grams of isobutene, 22.2 grams of MTBE and 31.0 grams of methanol can be obtained per hour from the top of the tower.

[0035] The obtained isobutylene enters from the bottom of the sulfur chlorination synthesis tower, and enters sulfur monochloride from the upper part of the synthesis tower at 3250 grams per hour. The reaction temperature was 40°C, and the obtained liquid mixture of sulfur-chlorinated isobutylene was 6062.3 g / hour, with a density of 1.16 and a sulfur content of 43.9%.

Embodiment 3

[0037] Operating equipment is the same as embodiment 1

[0038] Firstly, the MTBE cleavage reaction is carried out in the cleavage reactor. The reaction was carried out at a pressure of 0.60 MPa and a temperature of 120° C., and the feed rate of MTBE (96.88w%) was 6500 g / hour.

[0039] The reacted mixture enters the isobutene recovery tower with an operating pressure of 0.30 MPa, a tower top temperature of 40°C, and a reflux ratio of 1.6. 4075.5 grams of isobutene, 10.2 grams of MTBE and 19.7 grams of methanol can be obtained per hour from the top of the tower.

[0040] The obtained isobutylene enters from the bottom of the sulfur chlorination synthesis tower, and enters sulfur monochloride from the upper part of the synthesis tower at 3300 g / h. The reaction temperature was 40°C, and the obtained orange-yellow sulfur-chlorinated isobutylene liquid mixture was 6089.7 g / hour, with a density of 1.14 and a sulfur content of 42.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com