Method for preparing p-hydroxybenzene formaldehyde by diazo salt hydrolysis of p-aminobenzaldehyde

A technology of p-hydroxybenzaldehyde and p-aminobenzaldehyde, which is applied in the field of p-hydroxybenzaldehyde preparation, can solve problems such as unstable product quality, difficult process control, and low production efficiency, and achieve rapid temperature rise, reduced back-mixing, and improved The effect on product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

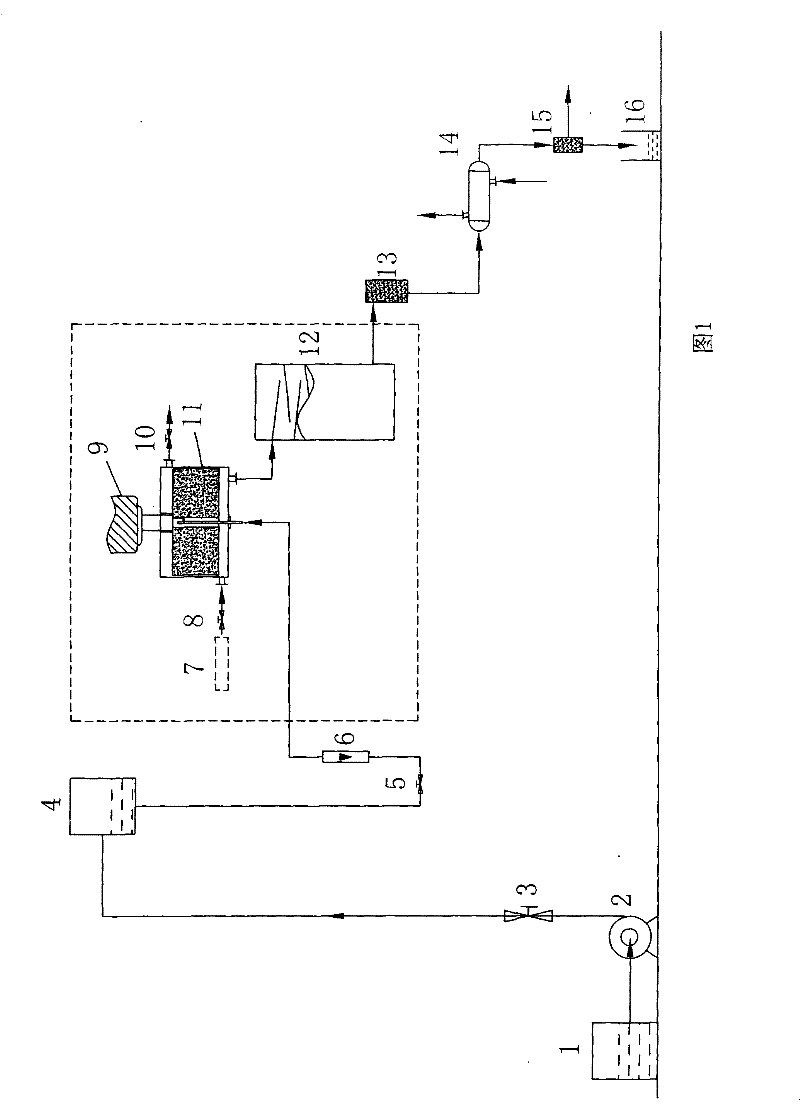

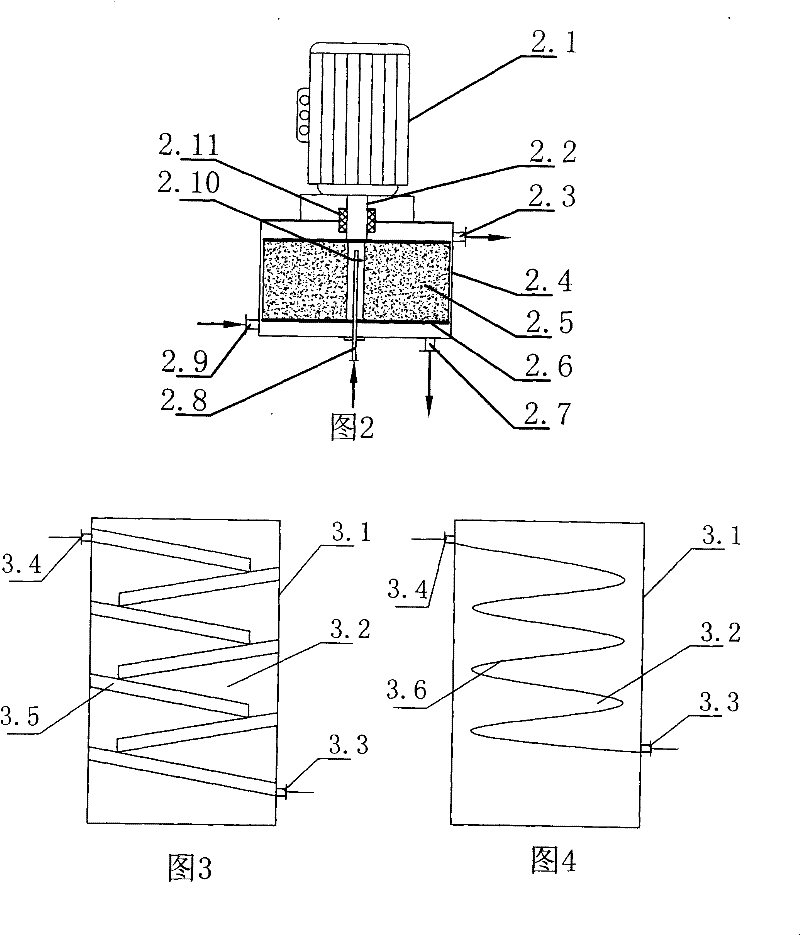

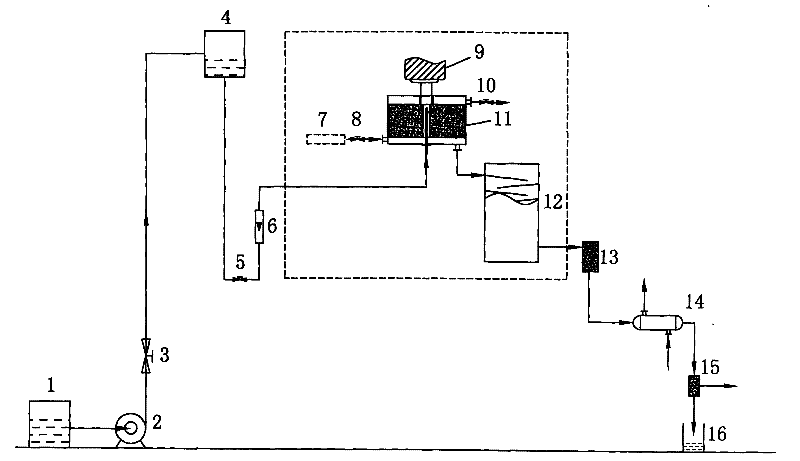

[0043] Put the diazonium salt solution of p-aminobenzaldehyde into the head tank 4 with the pump 2, open the hot air intake valve 8, heat the rotary packed bed 11 to 65°C, and adjust the rotating speed of the rotary packed bed 11 to 600r / min at the same time , open the discharge valve 5 of the head tank 4 to a certain opening, and adjust the flow rate of the raw material diazonium salt into the rotary packed bed 11 to be 1.0m 3 / h, the material enters the deflector tower 12 to continue post-reaction after mixing and preliminary reaction in the rotating packed bed 11, and the total residence time of the reaction materials passing through the rotating packed bed 11 and the deflector tower 12 is 140s. After the reaction is completed, the reaction solution enters the filter I13 equipped with activated carbon from the liquid outlet of the deflector plate tower 12 to filter out the oily by-product while it is hot, and then enters the tube condenser 14 to rapidly cool the gained hydro...

Embodiment 2

[0045] Use the pump 2 to pump the diazonium salt solution of the raw material p-aminobenzaldehyde into the head tank 4, open the hot air intake valve 8, heat the rotary packed bed 11 to 68°C, and simultaneously adjust the rotating speed of the rotary packed bed 11 to 600r / h min, open the discharge valve 5 of the head tank 4, and adjust the flow rate of the raw material diazonium salt into the rotary packed bed 11 to be 0.5m 3 / h, the material enters the deflector tower 12 to continue post-reaction after mixing and preliminary reaction in the rotating packed bed 11, and the total residence time of the reaction materials passing through the rotating packed bed 11 and the deflector tower 12 is 180s. After the reaction is completed, the reaction liquid enters the filter I13 equipped with glass wool from the outlet of the deflector plate tower 12 to filter while it is hot, and then enters the tube condenser 14 to rapidly cool the gained hydrolyzate to room temperature. After cooling...

Embodiment 3

[0047] Use the pump 2 to pump the diazonium salt solution of the raw material p-aminobenzaldehyde stored in the diazo liquid storage tank into the head tank 4, open the hot air intake valve 8, heat the rotating packed bed 11 to 72 ° C, and rotate the packing The rotating speed of bed 11 is adjusted to 800r / min, the discharge valve 5 of head tank 4 is opened, and the flow rate of raw material diazonium salt entering rotary packed bed 11 is adjusted to 0.5m 3 / h, the material enters the deflector tower 12 to continue post-reaction after mixing and preliminary reaction in the rotating packed bed 11, and the total residence time of the reaction materials passing through the rotating packed bed 11 and the deflector tower 12 is 180s. After the reaction was completed, the reaction liquid entered the filter I13 equipped with gac from the liquid outlet of the deflector plate tower 12 to filter while it was hot, and then entered the tube condenser 14 to cool the gained hydrolyzate to roo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com