Tool and method for processing half-speed machine crankshaft

A technology for crankshaft processing and tools, which is applied in the field of medium-speed machine crankshaft processing tools and processing, can solve problems such as difficult quality assurance, low production efficiency, and inability to meet the requirements of mass production, so as to achieve the effect of ensuring product quality and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

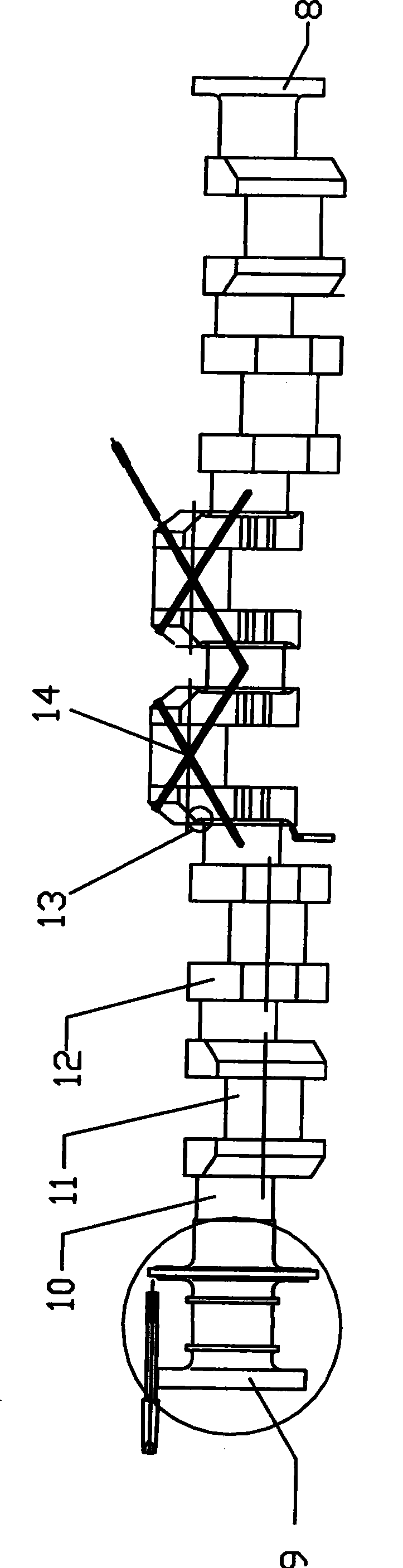

[0031] refer to image 3 , Figure 4 , The crankshaft of the medium-speed machine is mainly composed of free end 8, thrust end 9, main journal 10, turning neck 11, turning arm 12 and other parts. There are also load relief grooves 13, φ20 crossing oblique oil holes 14, and balance block surfaces 15 on it.

[0032] The processing method of the present invention is, first press TR pier forging to form medium-speed machine crankshaft blank according to the traditional method, then carry out the main journal, turning neck, discharge groove and output end, free end flange, milling balance block, crank arm shape , Drilling and machining of evenly distributed holes and screw holes on the end face of the flange, grinding the main journal and turning neck, and finishing. Then use the medium-speed machine crankshaft machining tool of the present invention to process load relief groove, balance block surface, φ 20 oblique oil holes and φ 700 flange holes.

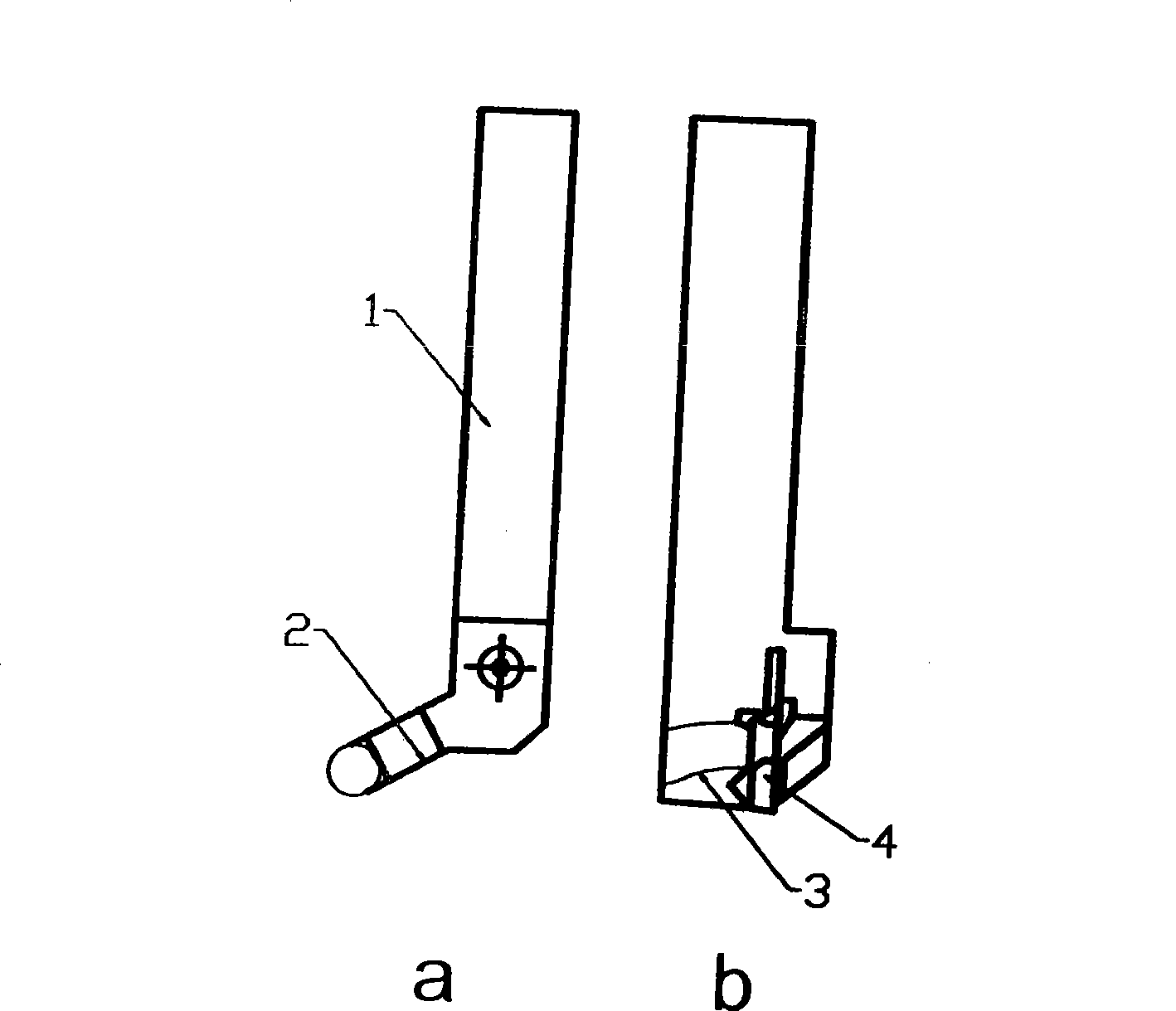

[0033] refer to figure 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com