Method for processing high-precision bearing adapter sleeve

A processing method and adapter sleeve technology, applied in the directions of bearing components, shafts and bearings, metal processing equipment, etc., can solve problems such as offset and deformation of the rotation center of the workpiece, and achieve no vibration and noise, improved service life, and stable bearing operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Processing technology for producing high-precision bearing adapter sleeves:

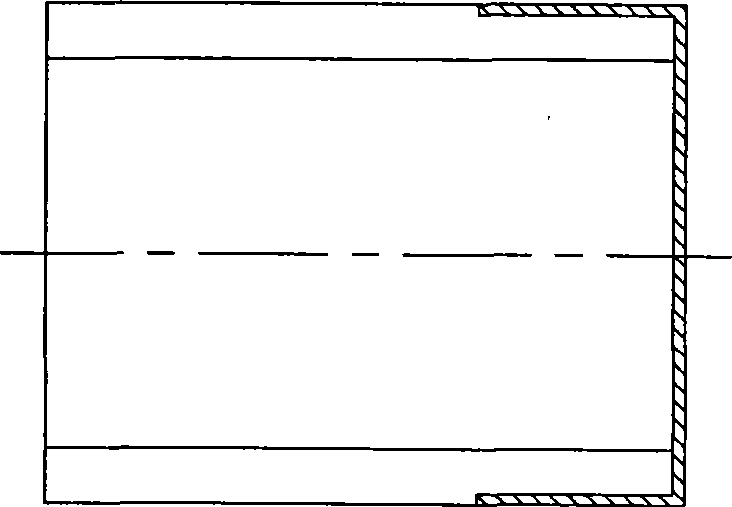

[0040] The general process method of the present invention adopts the one-time clamping molding process of the numerical control machine tool. Take the processing of H318 as an example, such as figure 2 The tube blank is selected as shown, the outer diameter of the tube is φ95, the inner diameter is φ76, and the width B1=68

[0041] Processing method of the present invention is as follows:

[0042] 1. Internal stress relief annealing:

[0043] 30KW well-type resistance furnace, heating up to 730°C, holding for 1.5 hours, then cooling down to below 200°C with the furnace.

[0044] 2. Machining datum surface: such as figure 2 shown

[0045] φ93 +0.1 Datum surface out of roundness ≤0.03

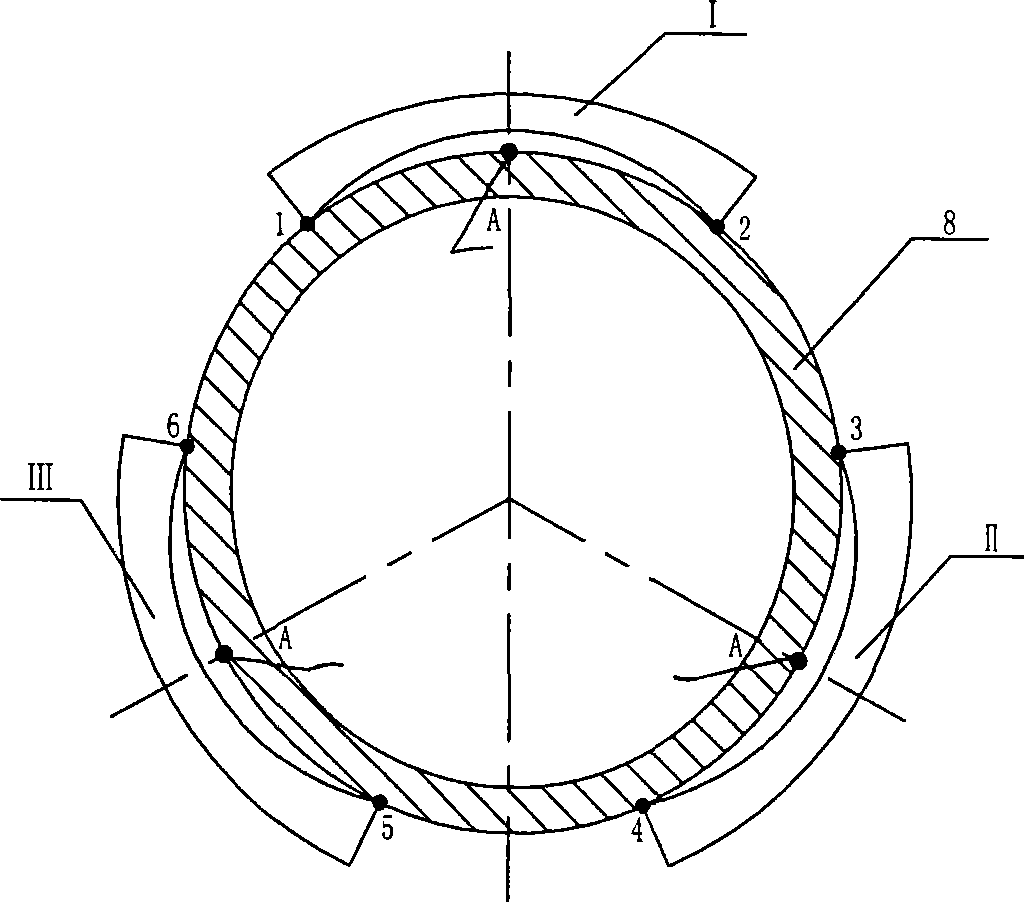

[0046] 3. Car hydraulic automatic chuck jaws: the turning diameter of the three jaws is φ92-0.1, and soft jaws are used. The arc length of the three soft jaws is not less than 1 / 3 of the circumference o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com