Bastard tamarind legume extract, and preparation method thereof and anti-bacteria agent

A technology of extracts and antibacterial agents, applied in the fields of Albizia Julibrissin pod extract and its preparation and antibacterial agents, can solve the problems of underutilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

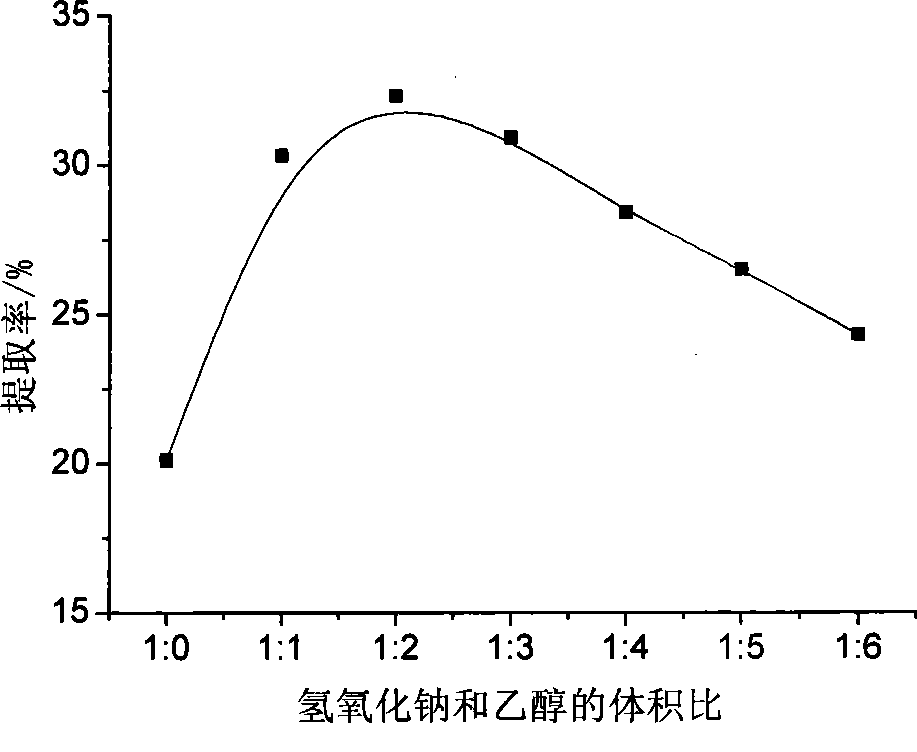

[0024] Embodiment 1: the selection of extraction solvent

[0025] Get 50g and crush it to 8 meshes of Albizia juliensis pods, use an extraction solvent consisting of 150mL of industrial alcohol with a concentration of 95% by volume, 50mL of NaOH solution with a mass fraction of 6%, and 100mL of industrial alcohol, or 150mL of a NaOH solution with a mass fraction of 3%, or 150mL Water, or 150mL of 3% hydrochloric acid solution with a mass fraction of 150mL, respectively, reflux at 80°C for 3 hours, filter while hot, repeat three times, and combine the three extracts.

[0026]Adjust the pH value of the extracted extract to 4-6, then rotate and distill it to 1 / 2 the volume of the original extract; directly add 10 g of 80-mesh silica gel to the industrial alcohol extract, stir evenly, and continue distilling until a loose powder is obtained. The loose matter and the loose matter are separated and extracted in a Soxhlet extractor with the separation solvent petroleum ether, diethyl...

Embodiment 2

[0031] Embodiment 2: Selection of extraction time

[0032] Mix 50mL of NaOH solution with a mass fraction of 6% and 100mL of industrial alcohol to form the extraction solvent, take 20g and crush it into 5 parts of Albizia juliensis pods of 8 meshes, soak them in the extraction solvent respectively, and reflux at 80°C for 20min, 60min, 90min, respectively. 20min, 150min, filter while hot, repeat three times, and combine the three extracts.

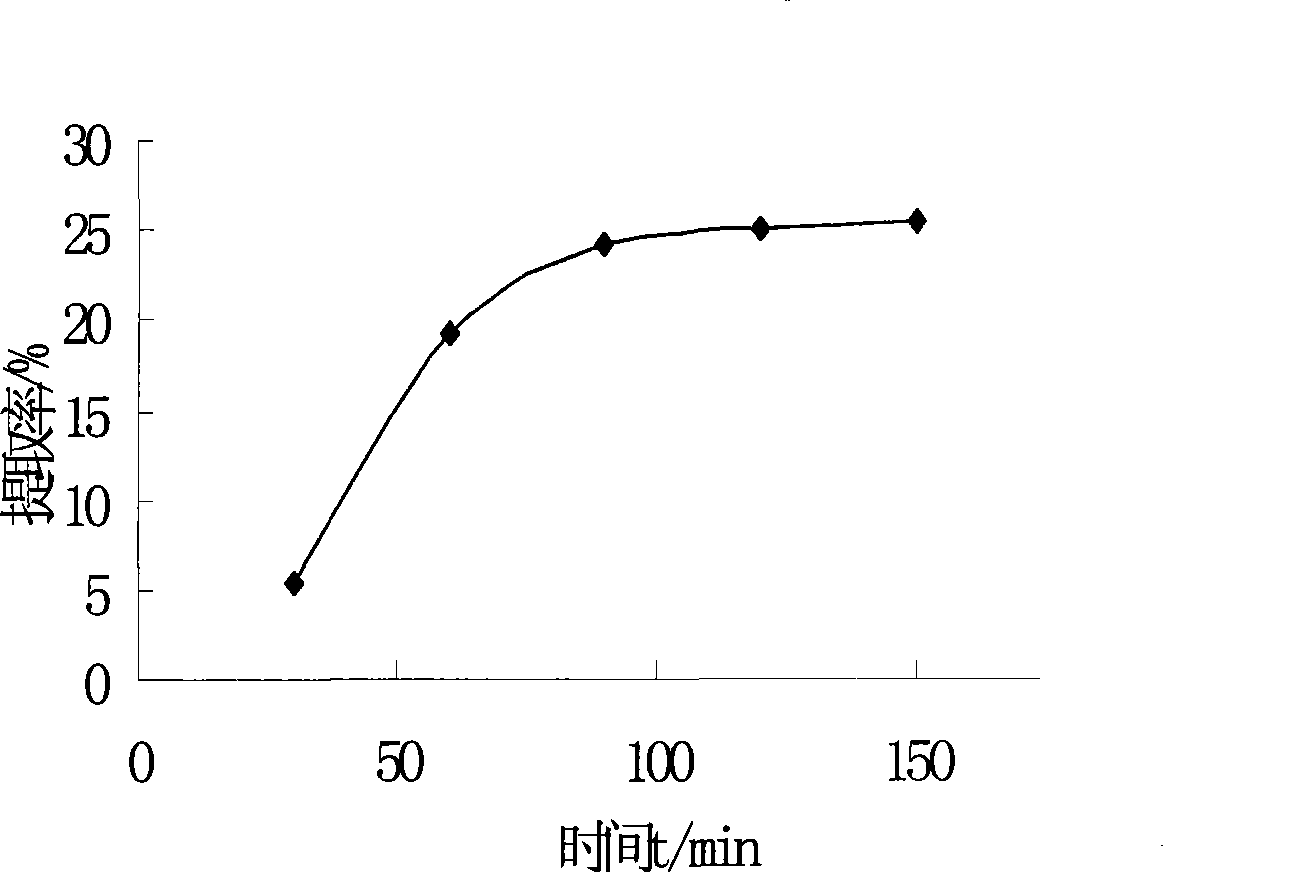

[0033] Use hydrochloric acid to adjust the pH value to 4-6, and then distill under reduced pressure, distill to 1 / 2 volume of the original extract, and use separation solvent petroleum ether, diethyl ether, ethyl acetate, normal Butanol is extracted in a separatory funnel; the extraction phase of each separation solvent is distilled to obtain extracts of different extraction solvents, and the extraction rate is calculated according to the above formula for calculating the extraction rate. For specific values, see figure 1 . from figure 1...

Embodiment 3

[0034] Embodiment 3: the selection of the crushed particle size of pods of Albizia Julibrissin

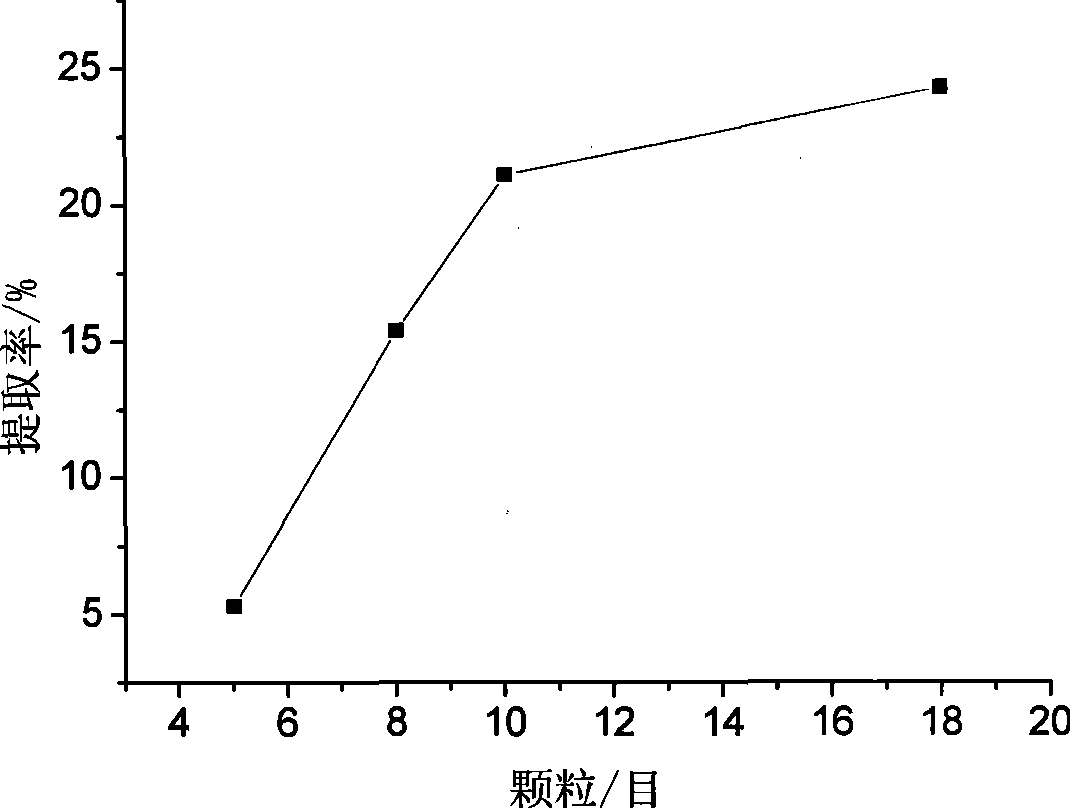

[0035] The specific operation is the same as the above-mentioned Example 2, the fixed extraction time is 90min, and the particle size of Albizia juliensis pods is 5 mesh, 8 mesh, 10 mesh, and 18 mesh respectively, and the extraction rate is calculated according to the above formula for calculating the extraction rate. The results show that the larger the mesh number, the smaller the particles and the higher the extraction rate, but the smaller the particles, the more difficult the subsequent separation. Therefore, the best particle selection is 8-10 mesh. see results figure 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com