Method for the production of copper-chromium contacts for vacuum switches, and associated switching contacts

A manufacturing method and technology of switch contacts, applied in contacts, electric switches, high-voltage/high-current switches, etc., can solve problems such as unfavorable switching and burning characteristics, and achieve improved switching characteristics, high economy, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

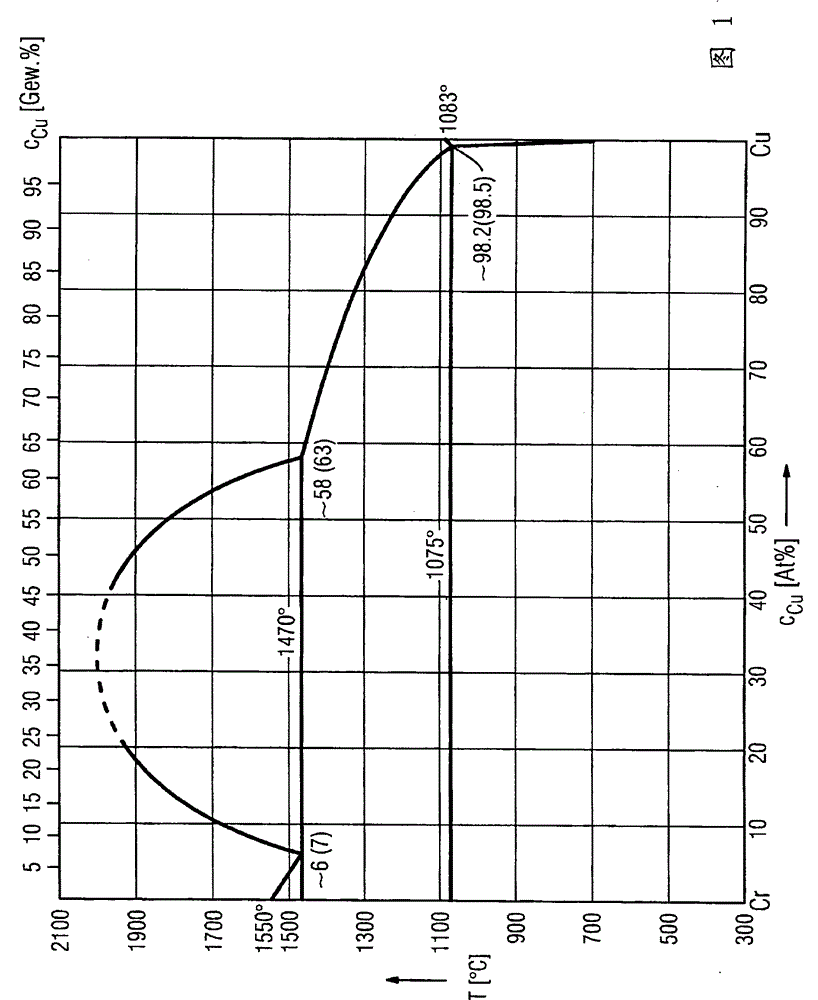

[0028] figure 1 The chromium-copper phase diagram is shown in such a way that 100% chromium content is plotted on the left and 100% copper content is plotted on the right. Chromium is known to have a relatively high melting point, namely 1550°C. In contrast, copper has a relatively low melting point of 1083°C. The eutectic forms at a temperature of 1075° C. at a copper content of 98.2. There is a narrow solubility range for chromium below the melting point of copper. In addition, solid copper and chromium are insoluble in each other below 700°C.

[0029] In addition, the chromium-copper phase diagram is also characterized by a mixed gap (Mischungslücke) in the liquid state, in which a metaeutectic is formed: above the metaeutectic temperature of 1470 ° C, between about 6% copper and 58% copper Two different mutually immiscible CuCr melts occur up to a temperature of approximately 2000° C.

[0030] The latter means for the practical manufacture of a homogeneous copper-chro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com