Organic acid type roughening liquid

An organic acid and coarsening liquid technology, applied in the field of organic acid type coarsening liquid, can solve the problems of short service life and frequent replacement, and achieve the effects of ensuring quality, prolonging service life, and strong resistance to impurity ion pollution.

Active Publication Date: 2010-11-10

SHENZHEN BANMING SCI & TECH CO LTD

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the organic acid type roughening solution is easily interfered by impurity ions such as tin and iron, and has a short service life and frequent replacement

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment approach 1

specific Embodiment approach 2

specific Embodiment approach 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

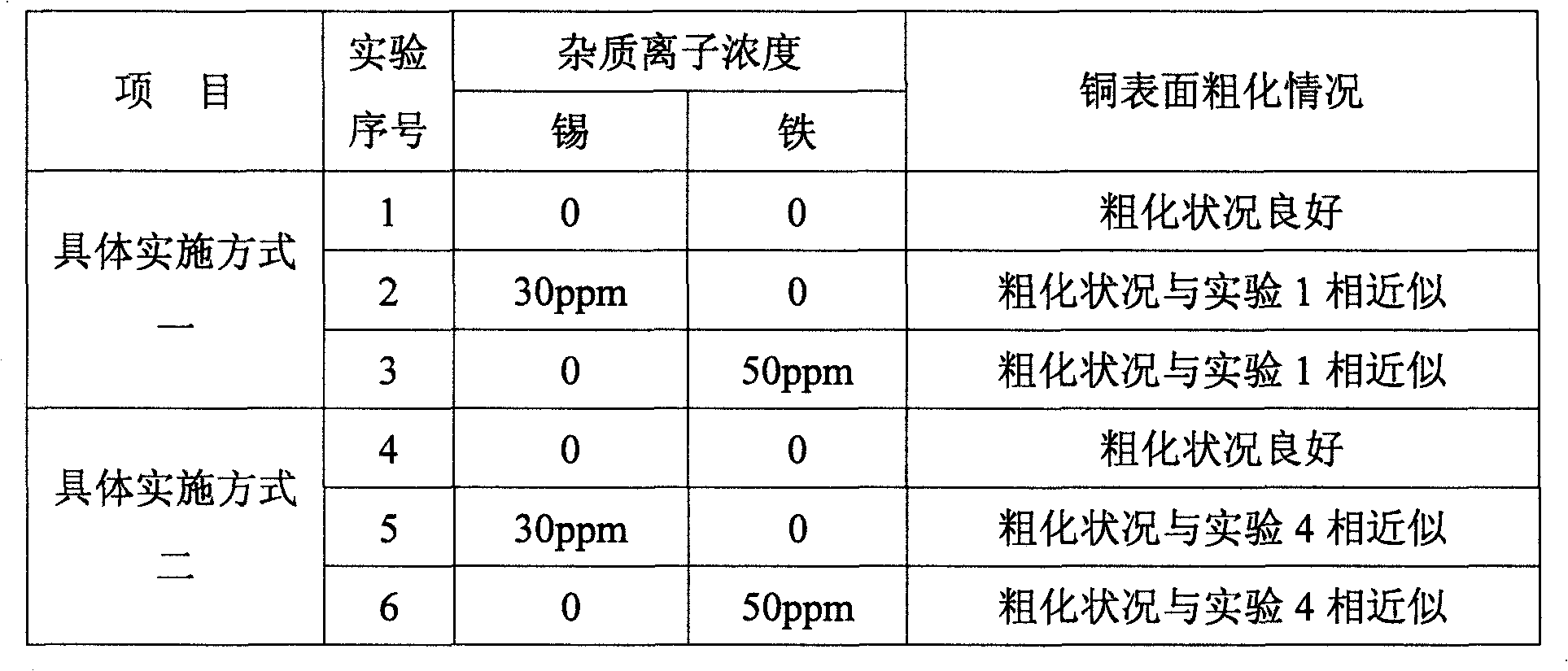

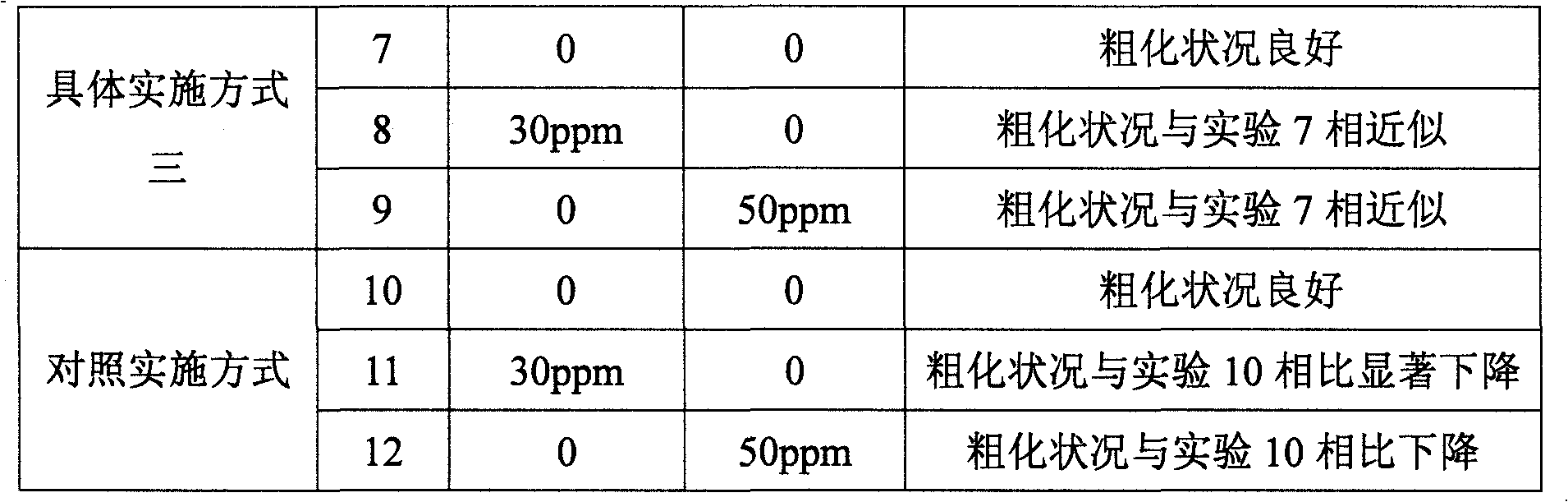

The invention discloses an organic acid roughening solution, the ingredient of which comprises organic acid; the organic acid roughening solution is characterized in that the ingredient of the organic acid roughening solution comprises 0.1-3.0% of impurity ion masking agent by percentage composition. Compared with the prior art, the organic acid roughening solution has the beneficial effects that: by adopting the impurity ion masking agent, the organic acid roughening solution can effectively solve the problem that the roughening solution is easy to be interfered by impurity ions such as tin,iron, and the like; the organic acid roughening solution reduces the time by which the roughening solution is replaced during the surface treatment technique of the copper used for a printing circuitboard and prolongs the service life of the roughening solution. The organic acid roughening solution has the advantages of strong capability of impurity ion pollution resistance, large process tolerance and convenient use; furthermore, under the condition of identical small copper corroding amount, the roughening degree of the surface of the copper is high; therefore, the organic acid roughening solution can obviously reinforce the adhesion of the surface with other coating or polymer and ensure the quality of coating and electro-plating or chemical-plating treatment.

Description

An organic acid type roughening solution technical field The invention relates to a composition for chemical etching of metal materials, in particular to an organic acid type roughening solution. Background technique Roughening solution is a chemical for micro-etching of conductive metal surface specially used for printed circuit boards, also known as micro-etching solution. It can completely remove oxides on the surface of conductive metal, and moderately roughen the surface of conductive metal to increase the specific surface area of its surface , and then enhance the bonding force between its surface and other coatings or polymers to ensure the quality of film and electroplating treatment. Existing roughening liquid includes peroxide type and organic acid type, and the roughening liquid of organic acid type discloses a kind of surface roughening of copper or copper alloy containing non-ionic group macromolecule compound as Chinese invention patent CN1629357A agent, w...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C23F1/18C23F1/16

Inventor 黄志齐黄京华郝意

Owner SHENZHEN BANMING SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com