Dissolvant type polyurethane curing agent synthetic method for producing low free toluene diisocyanate content

A technology of toluene diisocyanate and polyurethane curing agent, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of high content of toluene diisocyanate, narrowing difference in reactivity and high reaction temperature, and achieve low content of free toluene diisocyanate. , low production cost, good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

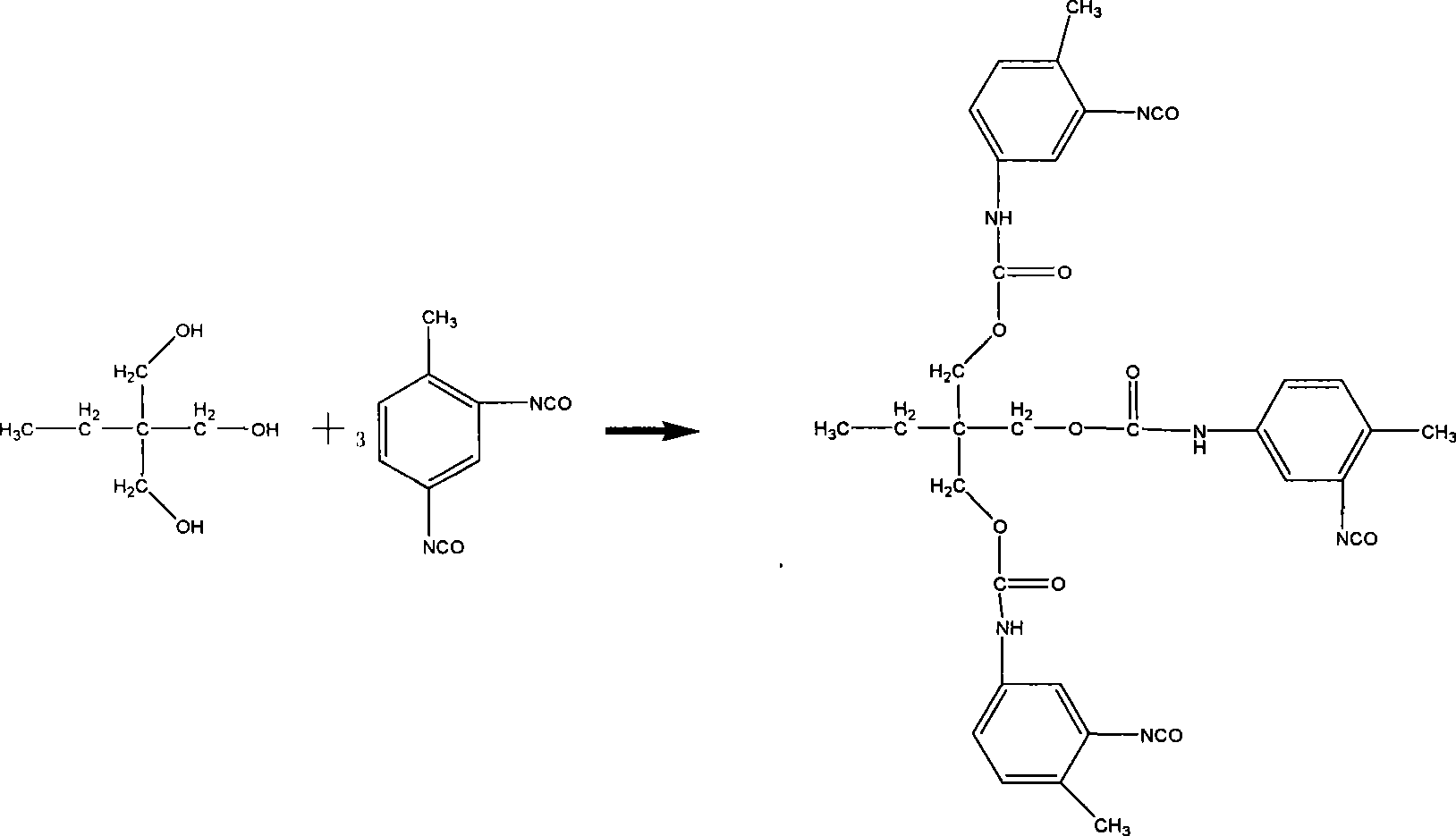

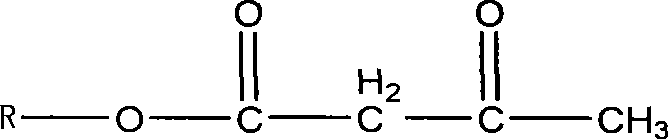

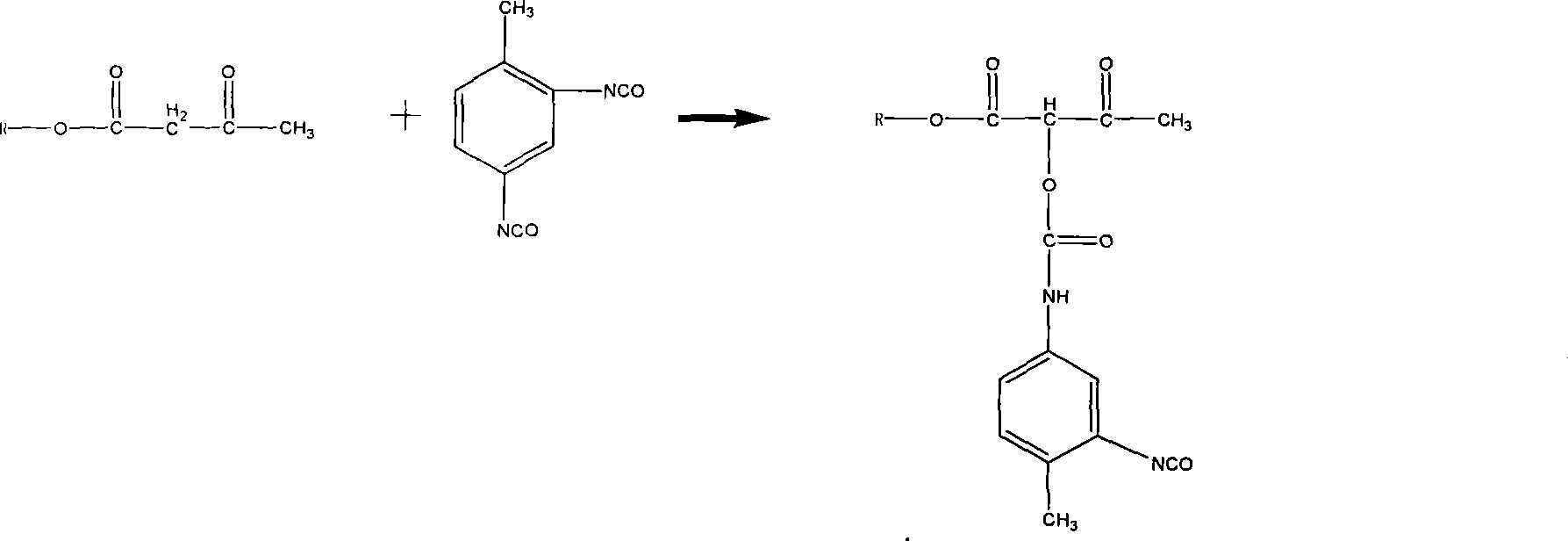

Method used

Image

Examples

no. 1 example

[0052] In the reactor that stirring, nitrogen and thermometer are installed, drop into 522 grams of toluene diisocyanate and 227 grams of butyl acetate as solvent, start stirring, and start to heat up. When the material temperature of the mixture in the reactor reached 50° C., 134 grams of trimethylolpropane was started to be added dropwise. The molar ratio of NCO / OH in toluene diisocyanate and trimethylolpropane is 2:1. The dropwise addition time is about 1 hour. After the dropwise addition of trimethylolpropane, keep the temperature at 50°C. During the heat preservation period, take a sample from the reactor every hour to detect the NCO content until the NCO content is stable, and the NCO content is 14.3%. During the above dropping process, turn on the freezer and set the outlet temperature of the chilled water to 15°C. When the outlet water temperature reaches 15°C and stabilizes, it is ready for use. When the NCO content is stable, stop heating immediately, remove the he...

no. 2 example

[0055] Same as the first embodiment, only the amount of trimethylolpropane triacetoacetate is replaced by 16 grams. Trimethylolpropane triacetoacetate accounted for 2.38% by weight of non-volatile matter.

[0056] The viscosity of the polyurethane curing agent product is 1500mPa.s, the NCO content is 13.93%, and the color is 20#. It is measured by Pt-Co colorimetry, and the free toluene diisocyanate content is 0.42%, and the non-volatile matter is 73.7%.

no. 3 example

[0058] Same as the first embodiment, only the temperature of the second low-temperature reaction is set to 25°C. Product viscosity is 2100mPa.s, NCO content is 13.42%, color is 20#, measured by Pt-Co colorimetric method, free TDI content is 0.46%, non-volatile matter is 73.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com