Control system for energy feedback-brake unit integrated machine of frequency conversion elevator

A brake unit and energy feedback technology, applied in the direction of motor generator control, control system, electrical components, etc., can solve the problems of elevator frequency converter not working normally, elevator not running normally, etc. Safe and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

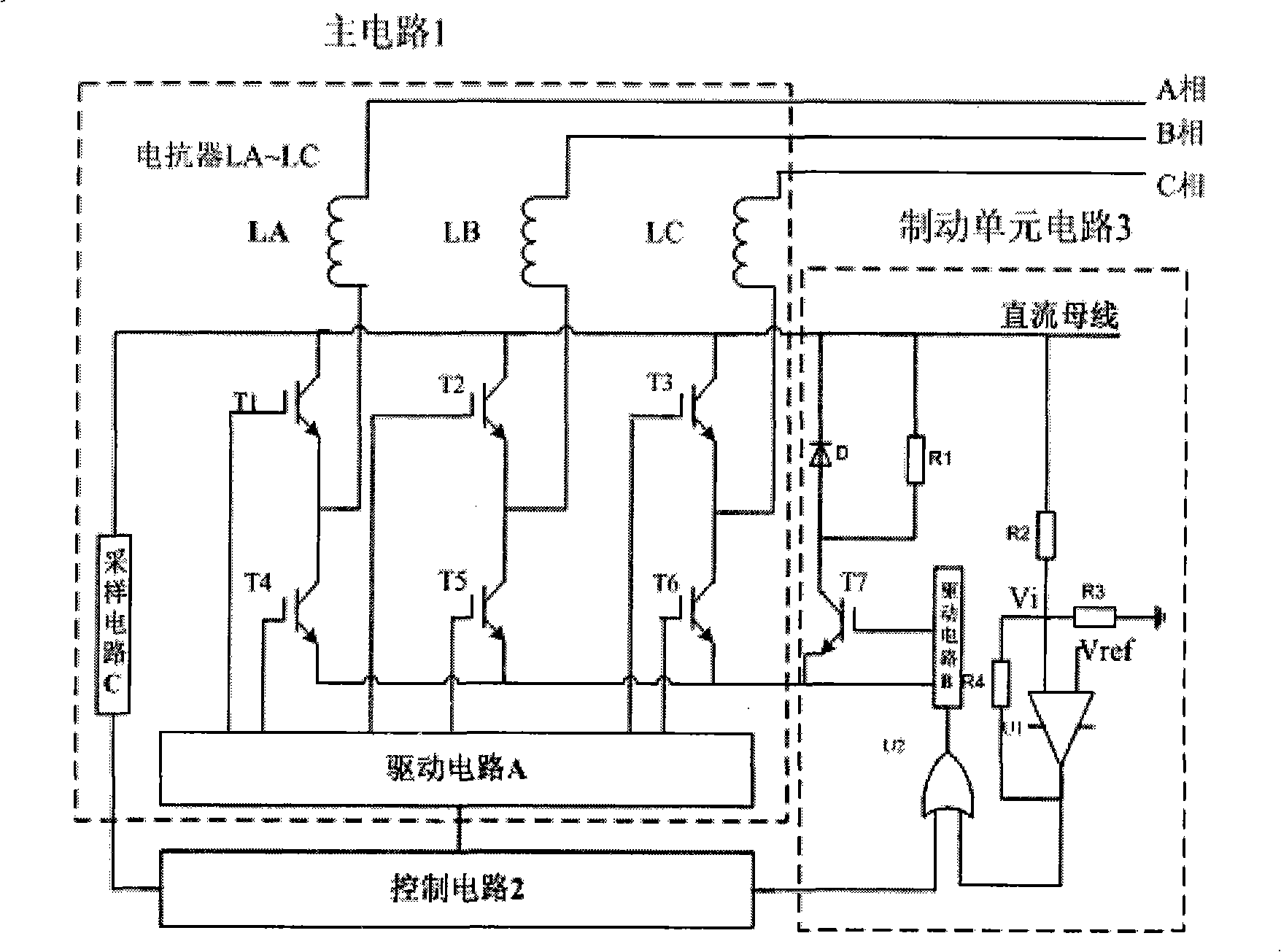

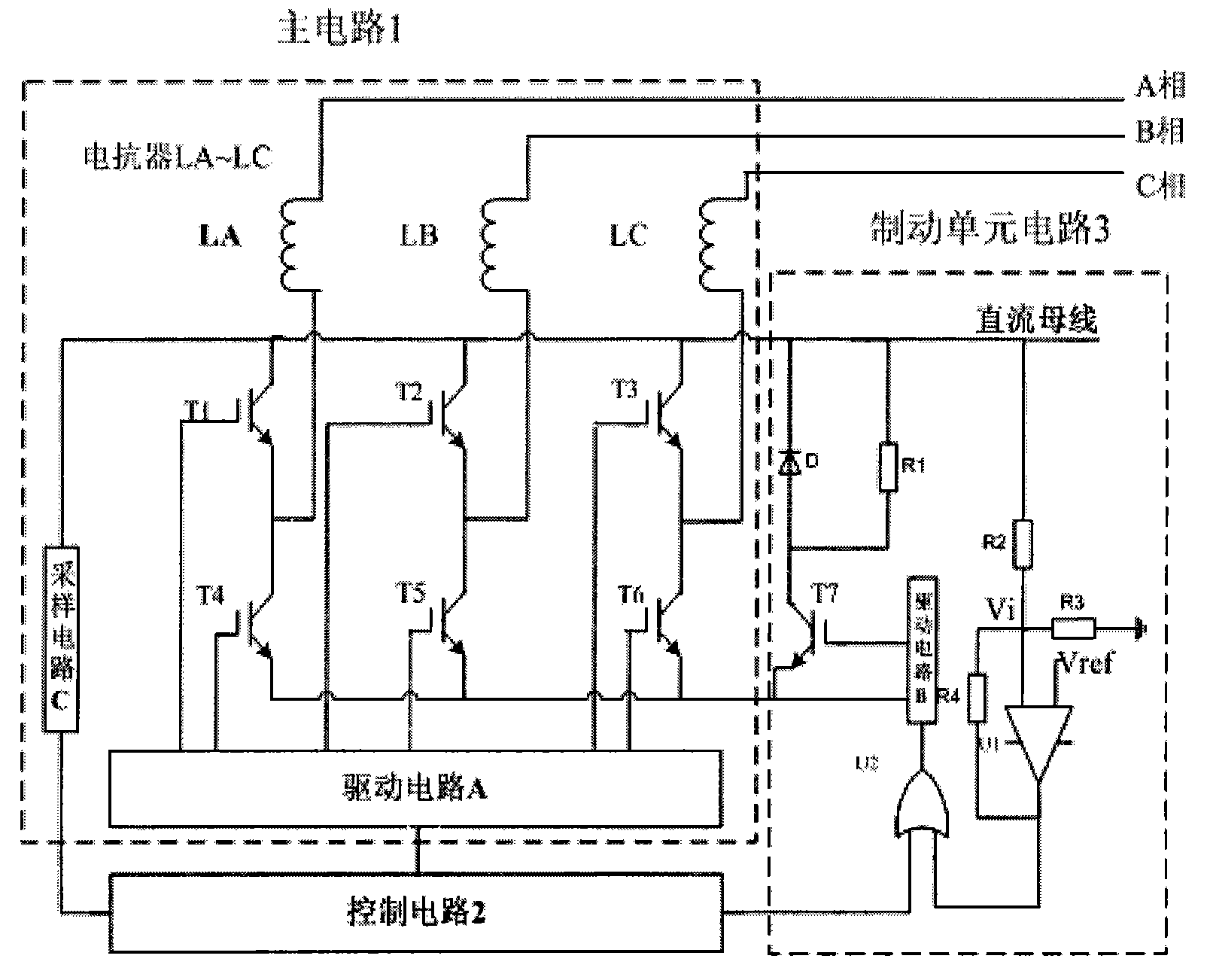

[0010] Further illustrate the present invention below in conjunction with accompanying drawing.

[0011] refer to figure 1 , the energy feedback-braking unit integrated control system of variable frequency elevators, including main circuit 1 and control circuit 2, the main circuit includes three-phase reactors LA, LB, LC, six switch tubes T1 ~ T6, drive circuit A and The sampling circuit C is characterized in that it also includes a braking unit circuit 3, and the braking unit circuit 3 includes a transistor switch T7, a transistor drive circuit B, a diode D, a comparator U1 and an OR gate U2, and a gate of the transistor T7 The pole is connected with an output end of the crystal switch tube drive circuit B, the collector of the crystal switch tube T7 is connected with the anode of the diode D and one end of the first resistor R1, and the emitter of the transistor switch T7 is connected with the six switch tubes of the main circuit The emitter is connected to the other output...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com