Two-locking bridge type stonecutter

A stone cutting machine, double locking technology, applied in the direction of stone processing tools, stone processing equipment, work accessories, etc., can solve the problems of easy damage of diamond cutter heads, increase time and cost, affect the quality of work, etc. Long life and good rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

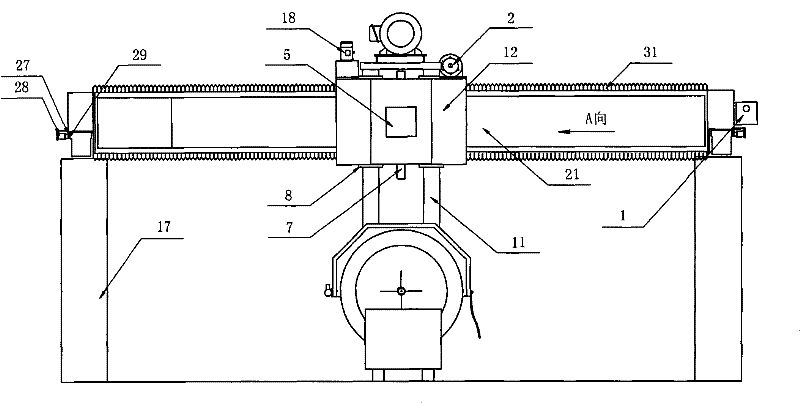

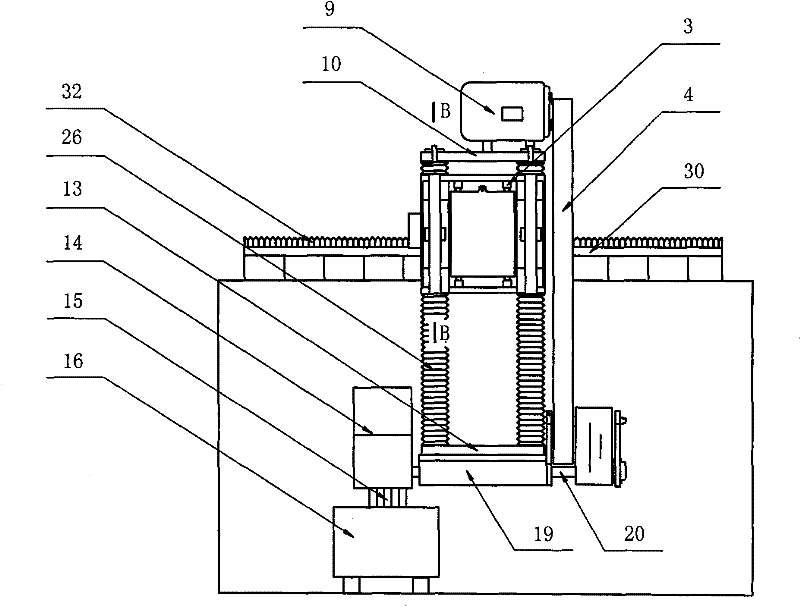

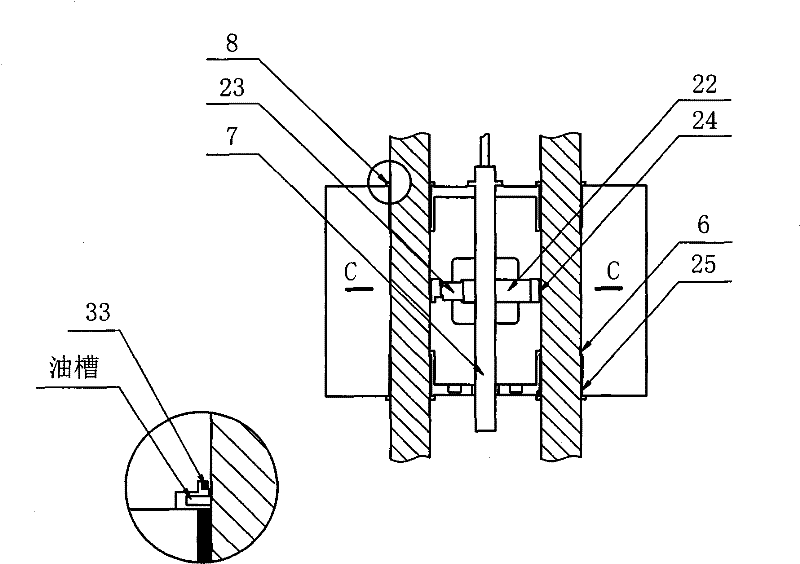

[0027] Such as figure 1 , 2 , 3, 4, 5, and 6 shown in double-locking bridge-type stone cutter, including machine pier 17, guide beam 30, girder 21, transmission device 1, 2, 4, hydraulic device 18, working parts, wherein the working parts It includes a body 12, a guide post 11, and a saw blade 15. Its structural features are: the stone cutter is equipped with a double locking device, and four sets of self-lubricating bearings 25 are installed in the body 12, and each set of self-lubricating bearings 25 is connected with a The guide post 11 is slidingly fitted, the self-lubricating bearing 25 and the guide post 11 are fitted with a combined double sealing device, the linear guide rail 3, the guide beam 30 and the girder are installed between the body 12 and the girder 21 passing through the body 12 21 is provided with a dust cover.

[0028]The double locking device is composed of a guide post hydraulic locking device and a girder hydraulic locking device, the guide post hydra...

Embodiment 2

[0035] Such as figure 1 , 2 , 3, 7, 8, 9 shown in the double locking bridge stone cutter, the double locking device is composed of the guide post cam locking device and the girder cam locking device, the guide post cam locking device is installed in the machine body, The girder cam locking device is installed at both ends of the girder. The guide post cam locking device is composed of a guide post locking cam 34, a guide post return spring 35, a guide post locking plate 22 and a guide post friction plate 24. The guide post friction plate 24 is fixed on the guide post locking plate 22, and the guide post locking plate 22 leans against the guide post locking cam 34; The girder friction plate 29 is composed of the girder friction plate 29 fixed on the girder locking plate 27, and the girder locking plate 27 leans against the girder locking cam 36; when the machine is in operation, the cam rotates at a certain angle to push the locking plate and the friction plate respectively I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com