Pumpkin seed oil extraction method using water enzyme method

A technology of pumpkin seed oil and water enzymatic method, which is applied in the direction of edible oil/fat, food science, application, etc., can solve the difference of extraction methods and the conditions of germination (bud length, temperature, humidity are difficult to control, not suitable for large-scale production And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0021] Embodiment 1: Determination of the optimal enzymatic hydrolysis conditions for the aqueous enzymatic method

[0022] Determine the pumpkin seed size of pumpkin seed oil produced by aqueous enzymatic method:

[0023] Use a high-speed universal cell grinder to crush the pumpkin seeds for 5 seconds (note that the degree of crushing is not too high), and use a standard inspection sieve to screen out pumpkin seed powders with particle sizes of 0.325 mm, 0.5 mm, 1.0 mm, and 1.5 mm. Take 7g of raw materials with the above particle size respectively, and add 0.1mol / L acetic acid-sodium acetate buffer solution with a pH value of 4.8 at a solid-to-liquid ratio of 1:2. Add 0.5mL cellulase stock solution, enzymatically hydrolyze at 50°C for 2h, centrifuge, add 56mL n-hexane solvent to extract, and rotate to evaporate the oil sample. After constant weight, use the oil yield as an indicator to determine the optimum crushing particle size for pumpkin seed oil extraction Control withi...

Embodiment approach 2

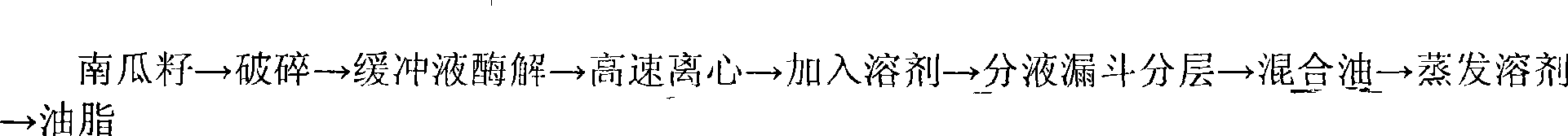

[0046] Embodiment 2: Extraction of pumpkin seed oil by aqueous phase enzymatic hydrolysis and organic solvent extraction

[0047] Use a high-speed universal cell grinder to crush the pumpkin seeds for 5 seconds (note that the degree of crushing should not be too high), take 7 g of pumpkin seed powder that has passed through a 0.5 mm aperture sieve, add 25500 U of compound enzyme, and then add 0.1 mol / L acetic acid-sodium acetate buffer solution to 21mL, enzymolysis at pH 4, 40°C for 4h, high-speed centrifugation (3000-10000r / min) of the solution obtained after enzymolysis to break the emulsion, adding 56mL of n-hexane solvent to the centrifugation liquid, extracting 3-4 times, and combining the extraction The oil sample was obtained by rotary evaporation, and the pumpkin seed oil yield was 38.34% after constant weight.

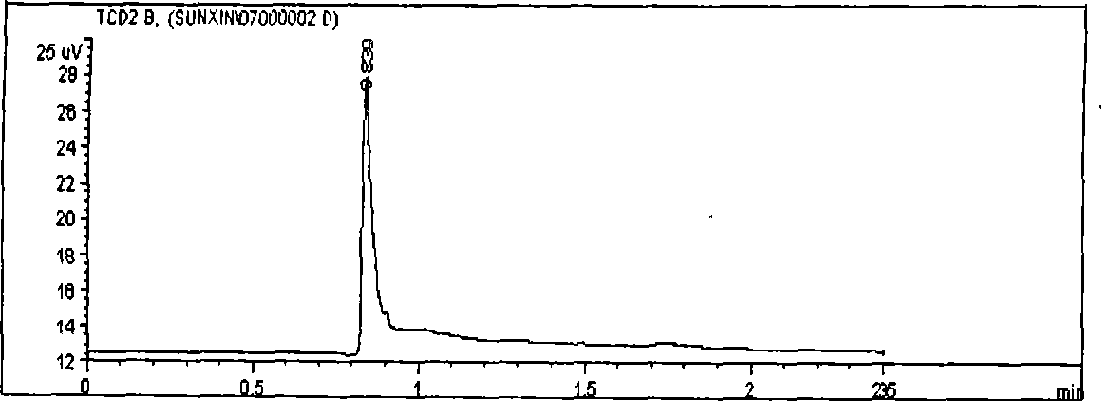

[0048] To test the residual determination of n-hexane in the aqueous phase enzymatic hydrolysis organic solvent oil extraction method.

[0049] 20g of pumpki...

Embodiment approach 3

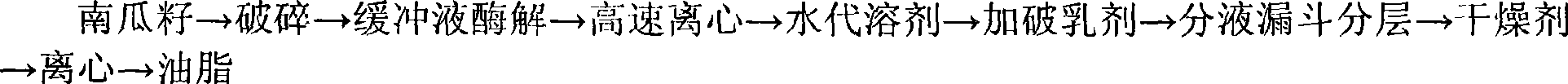

[0053] Embodiment 3: Extraction of pumpkin seed oil by aqueous phase enzymatic hydrolysis

[0054] Use a high-speed universal cell grinder to crush the pumpkin seeds for 5 seconds (note that the degree of crushing should not be too high), take 7 g of pumpkin seed powder that has passed through a 0.5 mm aperture sieve, add 25500 U of compound enzyme, and then add 0.1 mol / L acetic acid-sodium acetate buffer solution to 21mL, enzymolysis at pH 4, 40°C for 4h, high-speed centrifugation (3000-10000r / min) of the solution obtained after enzymolysis to break the emulsion, adding aqueous solution to the centrifuge to extract oil, adding demulsifier saturated NaCl solution 5-15mL , extracted 3 to 4 times, and added 0.1 to 0.3 g of anhydrous CaCl to the obtained oil phase 2 After drying and centrifuging, a clear, yellow-green oil is obtained, and the oil yield of pumpkin seeds is 37.40%. 100g of pretreated pumpkin seeds were weighed, and the scale-up experiment was carried out according...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com