Test construction for transistor

A technology for testing structures and transistors, which is applied in the direction of electrical solid-state devices, semiconductor devices, semiconductor/solid-state device components, etc., and can solve problems such as deviation from the standard value range and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

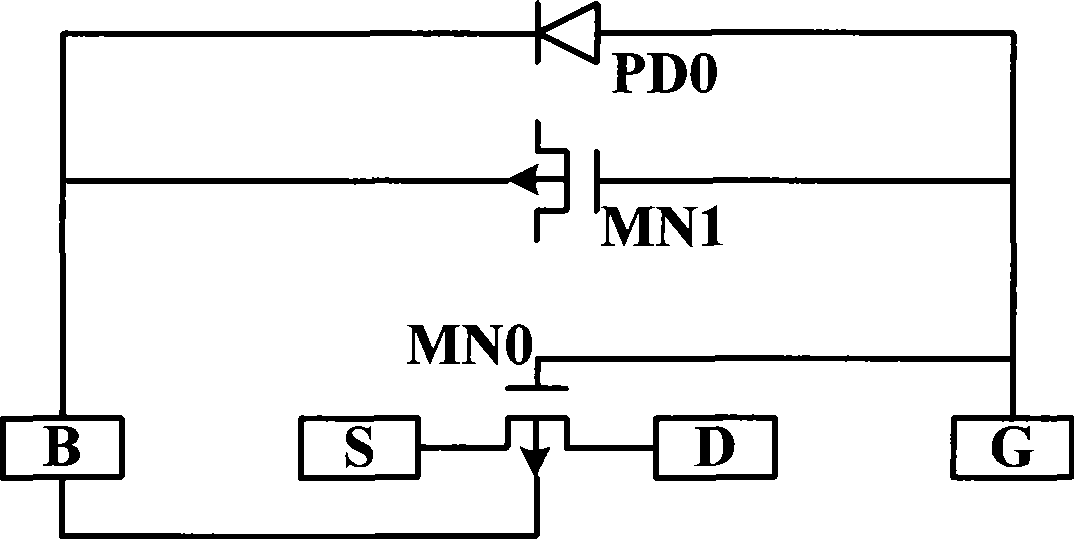

[0028] Please refer to image 3 , the test structure of the transistor in this embodiment includes a test transistor MN0, a protection transistor MN1 and a diode PD0.

[0029] In this embodiment, the test transistor MN0, that is, the transistor to be tested is an NMOS transistor. The protection transistor MN1 is used as a charge storage element to connect the gate G of the test transistor MN0 to the substrate B, that is, the gate of the protection transistor MN1 is connected to the gate G of the test transistor MN0, and the substrate of the protection transistor MN1 is connected to the substrate of the test transistor MN0 B connection, the protection transistor MN1 has the function of communicating AC and blocking DC, and the protection transistor MN1 is an NMOS transistor. The diode PD0 is used as a discharge element to connect the gate G of the test transistor MN0 and the substrate B, and the diode PD0 has the function of communicating AC and blocking DC. Therefore, the pr...

no. 2 example

[0039] Please continue to refer Figure 5 The difference between this embodiment and the first embodiment is that in this embodiment, a parallel plate capacitor C1 is used as a charge storage element connected between the gate G of the test transistor MN0 and the substrate B.

[0040] The transistor testing structure of this embodiment includes a testing transistor MN0 , a capacitor C1 and a diode PD0 . The test transistor MN0 means that the transistor to be tested is an NMOS transistor. The capacitor C1 is used as a charge storage element to connect the gate G of the test transistor MN0 to the substrate B. The capacitor C1 has the function of communicating and blocking DC, and the diode PD0 is used as a discharge element to connect to the test transistor MN0. The gate G of the test transistor MN0 and the substrate B, therefore, the capacitor C1 and the diode PD0 are connected in parallel between the gate G of the test transistor MN0 and the substrate B.

[0041] Figure 5 T...

no. 3 example

[0048] Please continue to refer Figure 6 The difference between this embodiment and the first embodiment is that in this embodiment, the transistor MN2 is used as a discharge element connected between the gate G of the test transistor MN0 and the substrate B.

[0049] The transistor testing structure of this embodiment includes a testing transistor MN0 , a first protection transistor MN1 and a second protection transistor MN2 . The test transistor MN0, that is, the transistor to be tested is an NMOS transistor, the first protection transistor MN1 is connected to the gate G of the test transistor MN0 and the substrate B as a charge storage element, and the second protection transistor MN2 is connected to the gate G of the test transistor MN0 as a discharge element and the substrate B, therefore, the first protection transistor MN1 and the second protection transistor MN2 are connected in parallel between the gate G of the test transistor MN0 and the substrate B.

[0050] Fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com