Auxiliary equipment for display substrate testing and display substrate testing method

A technology for display substrates and auxiliary equipment, which is applied in printed circuit testing, electronic circuit testing, etc., and can solve the problems of low design utilization rate, low efficiency, and increased manufacturing cost of display substrates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to improve the efficiency of testing the display panel unit of the display substrate and improve the design utilization rate of the display substrate, an embodiment of the present invention provides an auxiliary device for testing the display substrate and a testing method for the display substrate. In order to make the purpose, technical solution and advantages of the present invention clearer, the following examples are given to further describe the present invention in detail.

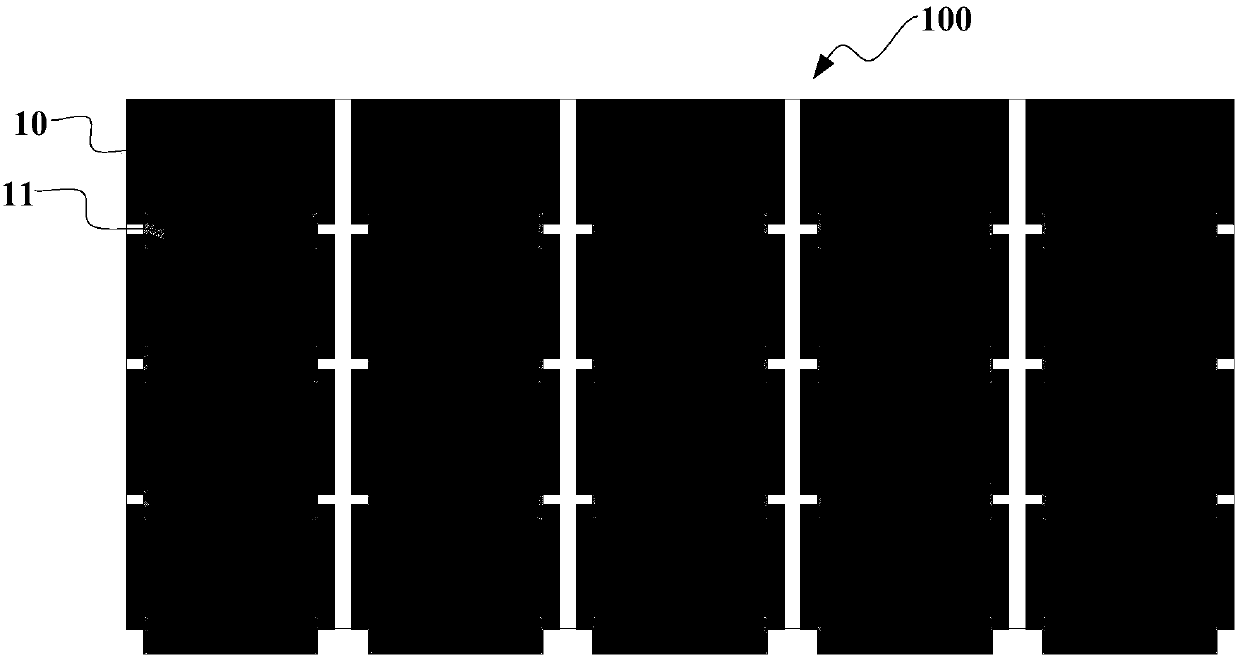

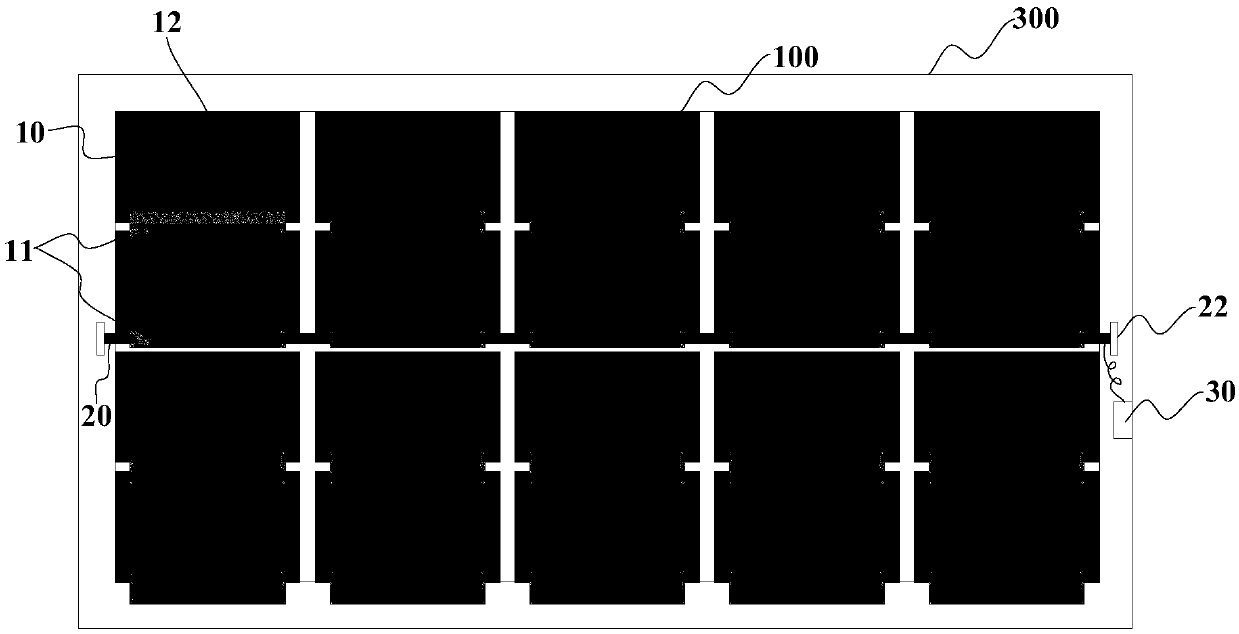

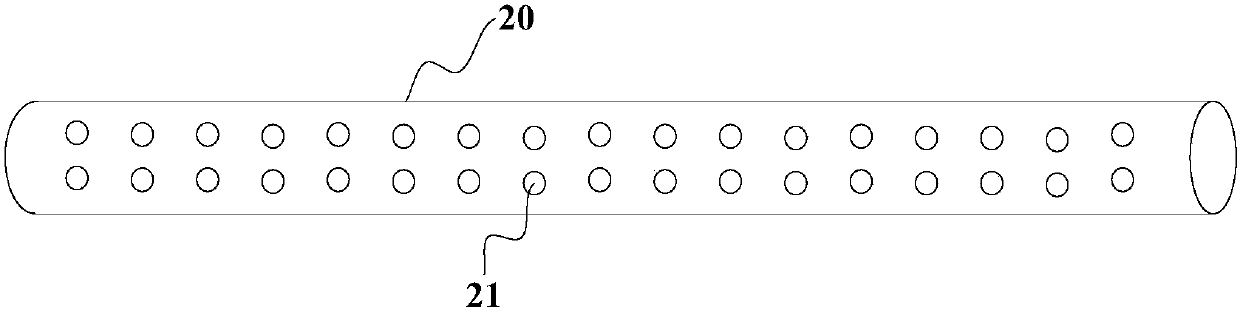

[0037] Such as figure 2 , image 3 and Figure 4 As shown, the auxiliary equipment for display substrate testing provided by the embodiment of the present invention includes a pressing roller 20 and a vacuum device 30, wherein: the pressing roller 20 is fixed above the binding area 12 of the display panel unit 10 of the display substrate 100, There are multiple vacuum suction passages 21 leading to the surface of the roller 20 ;

[0038] Optionally, the pressing rollers 20 may be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com