Measurement and control device used for eddy current retarder delivery inspection

An eddy current retarder and factory inspection technology, which is applied to measuring devices, instruments, measuring electronics, etc., can solve the problems of high labor intensity, complicated operation, and easy misjudgment, and achieve convenient, fast and automatic maintenance and equipment measurement The effect of high degree and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

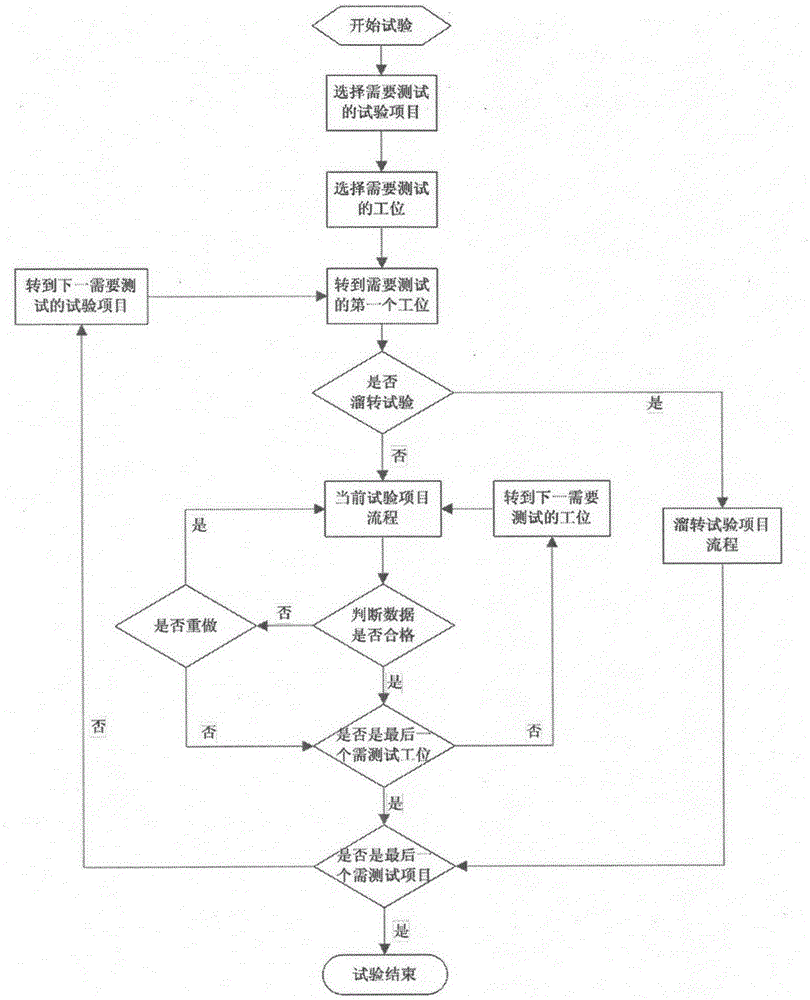

[0021] Such as figure 1 As shown, the measurement and control device for the factory inspection of the eddy current retarder in this embodiment includes an industrial control computer, and the industrial control computer is connected to a display, a barcode scanner, a printer and a communication card, and the communication card is connected to the measurement Instruments and meters, the measuring instruments and meters include a DC regulated power supply, a DC resistance meter, an insulation resistance meter, a power frequency withstand voltage meter, an electrical parameter meter and an I / O controller, and the communication card is connected to the DC regulated power supply, DC resistance meter, insulation resistance meter, power frequency withstand voltage meter, electrical parameter meter and I / O controller, the DC stabilized power supply, DC resistance meter, insulation resistance meter, power frequency withstand voltage meter, electrical parameter meter and The I / O contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com